Today, paper mills are completely focusing towards reducing the operational costs and increasing the operational efficiencies. Also there is a great competition on paper quality at the market place. So, the selection of right forming fabric plays an important role in helping the paper mills to achieve the desired results. To explore more on this team Paper Mart spoke with Mr. Amit Sharma, who has 17+ years of techno commercial industrial experience and is currently working as Asst. Vice President – Customer Solutions for Wires & Fabriks (S.A.) Ltd. Established in 1963, Wires & Fabriks is the leading manufacturer and supplier of paper machine clothing in India. The PMC product range includes forming fabrics constituting of single layer, double layer, triple layer and SSB, dryer screens, spiral linked screens and SS wire cloth. He shared with us some benefits of the STL forming fabric and how they are looking forward to create solutions for their customers.

.

Paper Mart: Tell us about your latest forming fabric developments?

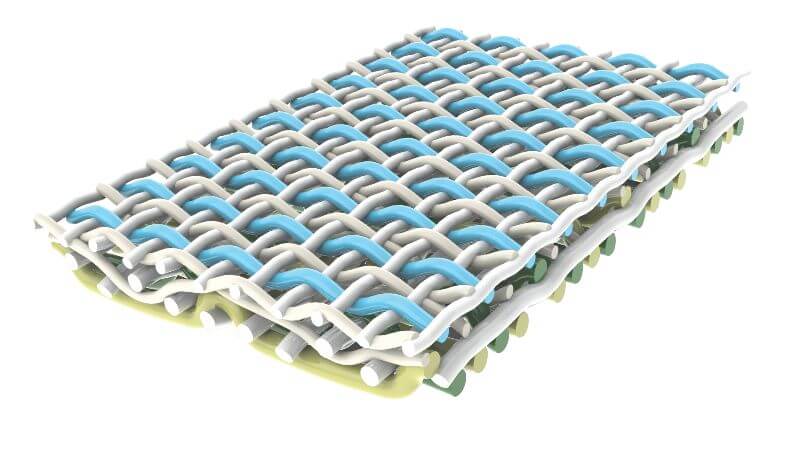

Amit Shrama: We had launched the fourth generation – STL (Shute Support Triple Layer) fabric about three years back in India and have made very significant progress towards establishing this product in the Indian market. When we started, we were the first and the only supplier making such designs in India. Recently many high-speed machines have been added in India and we have readily available best of designs to support these machines.

To support our product development we have made huge investments in our Jaipur facility on state-of-art machines from warping and weaving to heat setting, seaming and finishing. We also have in place the most sophisticated service equipment. I am happy to share that from our Jaipur facility, today we deliver products and services to over 20 countries.

PM: How do you compare it with best of the international product?

AS: We have a technical collaboration for latest forming fabrics with M/s Albany International – USA, the undisputed world leader of paper machine clothing. Albany has helped us in building our competence and has been a thorough support in our manufacturing applications, engineering and technical services for the SSB range what we call – STL (Shute Support Triple Layer).

PM: How has this product helped the industry?

AS: STL has been engineered and specifically designed to achieve better paper quality, mechanical stability, energy, chemical efficiency and better run-ability through various configurations. Some of the benefits that can reaped are improved retention, improved formation, less two-sidedness, better productivity, cleaner run, no wire marking, less drag load and high life potential. There are significant benefits experienced by customers who have upgraded from double layer to STL. But the benefits derived depend on machine parameters too.

PM: Does this fabric really help in the energy saving?

AS: Yes, the inherent MD stiffness in this fabric makes it deflect less into the slots of a vacuum assisted element. At a given speed, lesser deflection results in the electrical horsepower saving.

PM: What has been your achievement with respect to the value you have brought to the Indian customers?

AS: With this technology, we have opened the doors for the medium and some of the large scale mills which had only experienced and used the SL/DL forming fabric and were not really able to attempt the internationally available superior products because of high price, uncertainty of inventory and service. Wires & Fabriks has competitively made the STL designs available locally and is partnering with paper mills to deliver best solutions for all range of products. There are now more variants available within the STL category as we have launched new designs for packaging and specialty grades. We have a healthy reference list of improvements achieved with the STL forming fabric in India and abroad, which we do share with mills interested in switching over to STL.

PM: What would be your approach to further build the partnerships?

AS:Our approach would be to work very closely with the customers as a partner and not just as a vendor, to develop most optimized solution which is a combination of product and service keeping a clear focus on the paper machine efficiency, environment and energy. This consultative approach would involve a healthy participation from customer side as well. The partnership promises to deliver innovative products, service, support, education and key learning’s. Further, we have also engaged best international experts and consultants who frequently interact with our customer’s operations team and help us continuously upgrade our products and service delivery. We also encourage technical team visits from paper mills to our facility to have a first-hand feel of our capability and to see the progress we have made.

PM: How does this technical advisory work?

AS: Well, it is actually a scientific approach. If I were to share the critical components, it would constitute of identifying machine table profile, drainage profile allocation, identifying the needs in terms of paper quality, customer’s initiatives, supplying the recommended design and monitoring the performance. We also provide the research reports and the relevant statistical reports.