Increased knowledge about wood polymer interactions opens for a more sustainable future

By creative use of a combination of advanced analytical and evaluation methods, Swedish scientist Jasna S. Stevanic has managed to reach a new level of understanding of the ultrastructure and of the polymer interactions in the cell wall of spruce wood. This research project, carried out at Swedish research institute of Innventia, can make way for development of new types of renewable materials e.g. for the packaging industry, as well as a more energy efficient production of newsprint.

Over the years, paper makers have tried a number of methods for pretreating wood chips to save energy in refining. Many scientists have also tried to figure out how the strong and durable wood fibre could be imitated to produce new types of renewable materials. One obstacle in both cases has been the extreme complexity of the wood fibre. The understanding on the interactions between the different kinds of wood polymers is still incomplete. In her research, Jasna Stevanic has used a number of methods, e.g. dynamic mechanical analysis, DMA, imaging FTIR spectroscopy and dynamic FTIR spectroscopy.

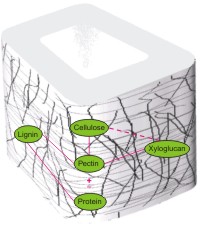

Dynamic FTIR spectroscopy in combination with dynamic 2D FTIR spectroscopy was used to examine how the lignin, protein pectin, xyloglucan and cellulose interact in the primary cell wall. The creative combinations of techniques being used proved very useful for studying molecular interactions in the complex polymeric systems of cell walls. By introducing minor stress to the material, and analyse the results with methods such as DMA and 2D FTIR spectroscopy, it proved possible to produce a complete map of the molecular interactions in both the primary and secondary cell wall. Based on the results, schematic pictures of the cross-linkages could be produced.

Imaging FTIR microscopy proved a very useful method in analysing the orientation of cellulose, glucomannan, xylan and lignin in the secondary cell wall.

New materials for the packaging market

Trying to build renewable materials for packaging, using wood fibre as the starting point, has been a goal for R&D within paper industry for a long time. Wood science, nano technology and other research areas have taken major steps forward, being close to the point where knowledge can be transferred into a number of new products. Maybe we are closing up on this point today.

- There is a great potential in using the interactions of the cell wall to build new materials, once we have a clear picture of the ultrastructure and polymer interactions, says Jasna S. Stevanic.

The results from the analytical part of the project indicated a parallel orientation of polysaccharides with respect to each other and the fibre axis and a partial parallel orientation of lignin. The results also indicated a strong interaction between cellulose and the hemicellulose glucomannan.

The next step of Jasna S. Stevanic’s research was to create a biocomposite film based on cellulose reinforced hemicellulose, thus utilizing the previous findings about the strong interaction between these polymers. Bacterial cellulose & rye arabinoxylan were used as model compounds in these experiments because of their purity, but the goal is obviously to use materials from waste material streams in pulp mills for industrial production of biocomposite products and therefore spruce galactoglucomannan and microfibrillated cellulose were also used.

The interactions were studied, using among other methods the DMA method mentioned above, based on the understanding of the ultra-structural organisation of the primary and secondary walls from earlier stages of the research. - This research may prove to teach us to synthetically build renewable materials with the unique material structures that give wood and other plant material such excellent qualities, says Jasna S. Stevanic. Plant materials show extreme resistance against variations in climatic conditions. By producing synthetic biocomposite materials, we can use the new knowledge about ultra-structure and polymer interactions in cell walls at the same time as we design materials to specific needs and also make them more homogenous.

Energy efficient newsprint with softening of cell wall

It is known from earlier trials that a low degree of sulphonation has a positive effect on energy efficiency of the refining process, and that a negative effect will occur if the sulphonation is taken too far. Jasna S. Stevanic managed to show exactly why this is, and describe the mechanisms involved. This new and deeper knowledge may lead to the development of efficient industrial procedures to considerably lower the energy demand in refining.

Jasna S. Stevanic managed to show that with a low degree of sulphonation, selective reactions caused a weakening of the interactions between three pair of polymers: lignin and pectin, lignin and protein, pectin and protein. The treatment resulted in an increased softening and swelling of the material, and contributed to a looser bond between the primary wall and middle lamella.

This explains the reasons behind the noted energy savings from a low sulphonation. The explanation of the negative effect from a higher degree of sulphonation seams to be that such a treatment moves into the secondary cell wall, where it causes effects on the lignin which makes the wood chips more difficult to refine. The strength of the secondary cell wall is not depending on the same polymer interactions that are weakened by sulphonation.

- The primary wall has always been very difficult and costly to analyze, says Jasna S. Stevanic. We may look at 10 000 € per gram just to isolate it. This has contributed to the fact that the interactions in this part of the wood cell walls have been insufficiently known. At Innventia I have had advanced microscopical and spectro-scopical instruments and methods available. We have also managed to utilize and combine analytical methods that helped us to put together an improved picture of polymer interactions in the primary wall.

Advancement through wide co-operations

Jasna S. Stevanic points to the fact that research in wood chemistry, nano technology and other material sciences now has advanced enough to be combined into common projects with the goal to produce new renewable materials with very interesting qualities. Jasna Stevanic work is also an example of wide cooperation, being largely financed by Formas Wood Wisdom NET and the Wallenberg Wood Science Centre, a research centre shared between the leading Swedish technical universities of Chalmers in Gothenburg and KTH In Stockholm.

- One example of promising combinations of research is the pilot scale plant for energy efficient production of nano cellulose now in operation at Innventia. This operation, combined with new knowledge in wood chemistry and Innventia’s competence in pulp and paper processes, may lead to interesting developments in the near future.

- Both aspects of Jasna S. Stevanic’s research will be subjects to further research at Innventia, says Lennart Salmén, Jasna’s supervisor, head of Fibre and Material Science group at Innventia and President of IAWS (International Academy of Wood Science).

About Jasna Stevanic

• Researcher at Innventia, Stockholm, since 2004

• PhD at Chalmers University of Technology 2011

• Licentiate at Royal Institute of Technology 2008

• Civ. Engineer at Sarajevo University 1998

About Innventia

Innventia is a leading R&D centre working with pulp, paper, graphic media, packaging and biorefining. Innventias aim is to translate research into innovative products and processes. Since April 2009 the name has been changed from STFI-Packforsk to Innventia.

Written by: Nils Lindstrand