Effective air and gas management is essential for high quality Paper and Board production. Complete deaeration of stock and wire water is still standard practice today with high-speed paper machines, especially those producing Printing & Writing grades. Effective air removal is also becoming more important for other grades, for example fast board machines utilizing recycled fiber as a raw material. Recently more attention has been focused on this area with smaller volume approach systems where the wire water is deaerated.

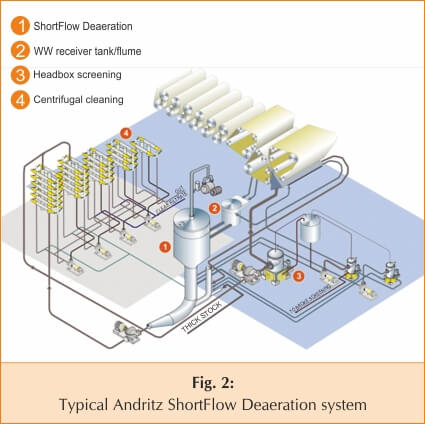

Andritz ShortFlow Deaeration is an advanced solution for partial air removal. This system combines the existing white water silo and conventional deaeration into one compact unit.

.

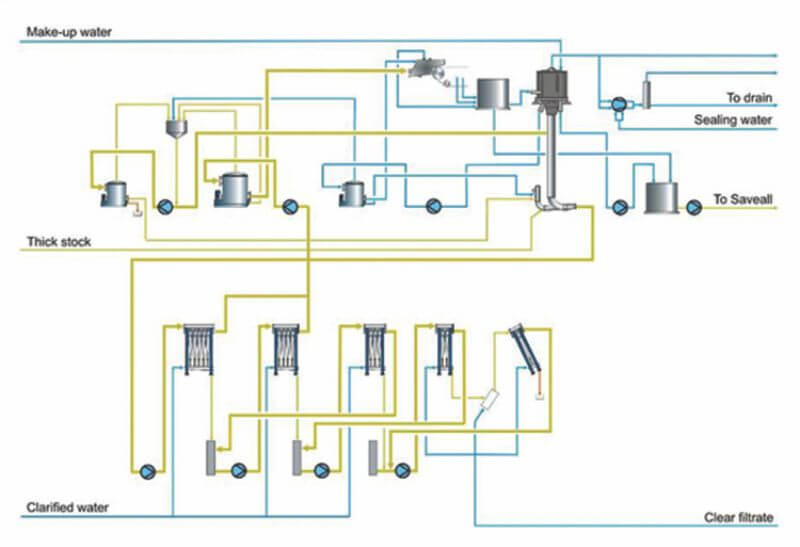

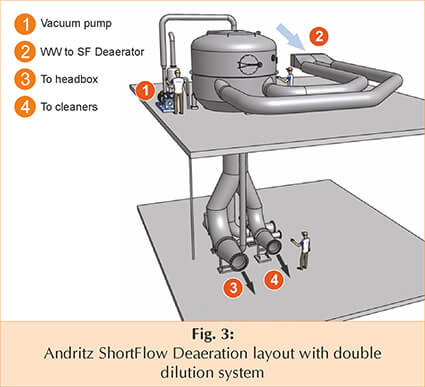

The ShortFlow Deaeration system collects wire water and former water to a deaeration tank, where a vacuum is applied. Water from the paper machine is transferred to the deaeration tank through the transition pipes. Water is brought to vacuum space above the liquid level in the deaeration tank in order to prevent air submergence. Simple entrained air removal from this water under vacuum makes the ShortFlow Deaeration system feasible. Boiling point vacuum is not required, which means that a single vacuum pump system is sufficient and no condenser is required. Optimized deaeration performance can be adjusted according to requirements of the paper machine. New ShortFlow Deaeration system is adaptable innovation to all paper and board making processes where complete deaeration is not required. It is applicable for new and existing paper machines. ShortFlow Deaeration enables the production of paper of high quality at minimized energy consumption and tank volumes. The very compact unit is built using short pipelines close to the paper machine. Stock preparation smaller volumes are reduced, which gives additional savings in energy and chemicals consumption.

Andritz ShortFlow Deaeration combines white water silo and conventional Deculator® deaeration system into one compact unit.

Features and benefits of ShortFlow Deaeration

FEATURES

• Easily adaptable design

• Flexible layout

• Single vacuum pump system

• No condenser required

• Variable speed drive for optimized vacuum adjustment

• Reduced amount of piping

• Reduced volume of approach system

• Best process cleanliness with polished surfaces

• Adaptable to all applications where complete deaeration is not required

BENEFITS

– High paper quality

…..• Better sheet formation

…..• High system stability

…..• Less pin holes

– High runability

…..• Improved drainage

…..• Increased productions

…..• Increased machine efficiency

…..• Reduced grade change times

– Reduced energy consumption

– Less cost

…..• Lower investment cost

…..• Less chemicals needed ( less defoaming chemicals and less biocides )

First Andritz ShortFlow Deaeration system on stream in Arctic Paper, Kostrzyn mill

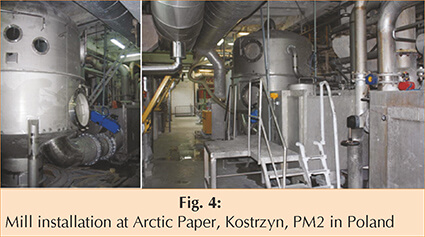

In January 2011, Andritz successfully started up the first new generation approach system with ShortFlow Deaeration at Arctic Paper, Kostrzyn, PM2 in Poland.

*Chief Technology Manager SP/PMA, Andritz OY, Kotka, Finland