Toxication and eutrophication of natural waters is a big problem in many countries. An increasing amount of ammonia in natural waters, soil acidification and smog disrupt the normal functioning of our ecosystems. Municipal sewage treatment works can minimise the ammonia concentration by applying the biological ANAMMOX® process.

Improve water quality and help the environment

In the anaerobic digestion of sewage sludge, nutrients such as nitrogen and phosphorus are barely removed. Returning the liquors derived from those plants back into the main treatment leads to accumulation of the nutrients and degrades the overall capacity of the wastewater treatment plant. Therefore, a dedicated treatment of the sludge dewatering liquids is necessary. Paques ANAMMOX® process is an effective and easy way to remove ammoniacal nitrogen from those liquors.

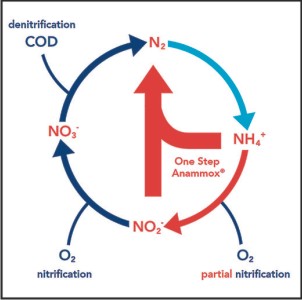

The natural nitrogen cycle involves various biological processes. Nitritation is the process where ammonium is oxidised to nitrite and nitrification is the process where ammonium is fully oxidised to nitrate. Denitrification is the process where nitrate with addition of an organic carbon source is converted to nitrogen gas. Anammox conversion is an elegant shortcut in the natural nitrogen cycle where ammonium and nitrite are converted to nitrogen gas. Anammox reactions in the world’s oceans are responsible for 30-50 per cent of the nitrogen in the air we breathe.

Paques ANAMMOX® is a reactor system in which nitritation and anammox conversion occur simultaneously in one single process unit. As the anammox process involves removal of ammonium over nitrite rather than nitrate less oxygen is required. The reactor uses granular biomass and is continuously aerated.

In comparison to conventional nitrification-denitrification the ANAMMOX® process does not require the addition of an organic carbon source. It can handle very high loads and has a superior biomass retention due to the granular biomass. This leads to a compact reactor footprint.

UK sewage treatment works saves money with ANAMMOX®

Minworth STW and Stoke Bardolph STW in the UK have chosen the ANAMMOX® technology for their sludge liquor treatment. Suffering from intermittent ammonia and sanitary limit failures both have chosen a biological, future-proof solution. Combined with Paques PHOSPAQTM process they also recover phosphorus from the liquors in the form of struvite. The investment results in a reduction of CAPEX of 60 per cent and OPEX of 40 per cent compared to conventional treatment.

The ANAMMOX® at Minworth is the world’s largest sludge liquor application. It was installed in existing tanks that saved a lot of money. In the case of Stoke Bardolph the project even won the UK AD & Biogas Award 2014 for Innovation in Sewage Treatment. “Paques ANAMMOX® technology is the most superior technology for sewage liquors and the award for this project is a true demonstration of Paques adagio: ‘revitalizing resources’” says Mr. Willie Driessen, Sales Manager UK.

The advantages

Paques ANAMMOX® reactor is far superior to conventional treatment methods. In comparison to nitrification-denitrification, ANAMMOX® has the following advantages:

- No organic carbon source required

- More than 60 per cent saving on aeration energy

- More than 75 per cent reduction of sludge production

- Easy control in one single continuously operated reactor

- Extensive knowledge with more than 20 installations worldwide.