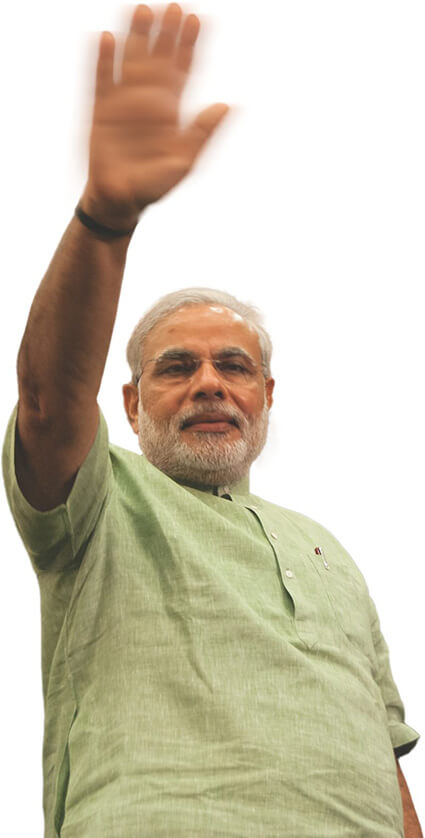

Everyone is very well versed with the political annotations of Mr. Narendra Modi, Chief Minister of Gujarat, India. On September 1st during the Federation of Paper Traders’ Association of India (FPTA) AGM he addressed the gathering of hundreds of people from paper fraternity about the importance of R&D in paper manufacturing, challenges for the paper industry etc.

He started his inaugural speech with the proud statement “it is heartiest to know that out of the total production of paper in India 35% is contributed by Gujarat so why not take it further as the state offers positive environment for industries to operate.” Usually paper mills have to generate their your own power to tackle the onslaught of power cuts but here in Gujarat being a power surplus state you have ample opportunity to establish and expand your base here. Another area where we need to focus more is on R&D. Worldwide the companies are doing R&D in different areas like raw material, processes, product development etc. India represents the biggest market for paper consumption as a population per se, though our per capita is really low as compared to other countries due to the cultural differences. Challenges are the part and parcel of whatever you do but it is unfortunate that being a country of more than 100 crore people where the quantum of waste is huge but still we need to import the waste paper from outside. To my mind it’s only because of policy paralysis in the waste collection system in this country. There is an immediate need to look on this issue in order to create necessary infrastructure for the collection system like segregation points, transportation etc. This will also create the employment opportunities for the people. Environmental concerns are on the rise so for the industries it’s tough to comply with the policies. Therefore there is a need to find out new avenues especially for raw-material supply for future. In Gujarat University some good research has been done on the fibre side, like to fetch the fibre from banana and make paper. Likewise we should involve the institutions both national and international to carry out new research. Most of the challenges faced by the industry are due to the usage of old technology, they were using earlier. Availability of water is another challenge wherein new ways have to be reached out to utilize the water to its minimum and recycle it further. It’s very unfortunate for us that it’s been 60 years since independence and till date the currency note paper is being imported from outside.

Mr. Manoharbhai Kothari – New President FPTA, Mr. Tej Raj Jain – Outgoing President

This is an era of global economy and our capacities have to be globally competitive so that when other countries dump their production here our product can give them competition in quality, price and service. Gujarat started its journey in 1960 and from 1960 to 2000 the total plan size of all 5 year plans were Rs. 55,000 crore. And this year 5 year plan size is Rs. 251,000 crore. In agriculture sector we have touched the growth of 10.7% throughout the decade whereas India hasn’t been able to reach to 3%. At last I invite all the paper manufactures present here to come and work here and we will provide you comfortable environment to work and grow.

.

“All in all China is ruling the pulp and paper market either as a supplier of paper or as a buyer of market pulp”

Mr. Yogesh Agarwal, COO, Ballarpur Industries Ltd gave the insight about the global market activities and stated “Many things are happening around the paper industry worldwide with regard to the business dynamics. India is in transition mode so is the paper industry. Market, raw material availability, energy scenario, consumer demand and environmental concerns all are in transition stage. Talking about the performance of the paper industry worldwide there is a significant compression on the demand side especially in USA relating to the segments like newsprints, coated and uncoated woodfree and metallic base in particular. This all is due to the onslaught of the digital media. As compared to 2008 demand statistics, newsprint and writing & printing grades are down by 17% and 8% in 2011 respectively. Currently Asia including China has emerged as the whopping market for writing and printing grades as compared USA and Europe, facing the compression of 30% and 20% respectively. As far as India is concerned it is still growing at good pace as compared to other countries. But, the present environment of high inflation rate and fiscal deficit has raised certain concerns. The rising population has to be supported by the different factors like creation of employment opportunities to avoid India to be a demographic disaster.

China is also facing the slowdown in demand in many of its industries including paper. The surplus capacity of paper in China has been dumped in to Asia Pacific region including India, Middle East and Africa. While writing and printing demand has shrinked by 8% in the 2011 as compared to 2008, in the same period market pulp has grown by 10% globally. The market pulp demand in China has grown at the CAGR of 14%, which shows the demand of non-integrated players has increased significantly. All in all China is ruling the pulp and paper market either as a supplier of paper or as a buyer of market pulp. Global priorities are now shifting from political concerns to economic agenda. Our global democratization has brought us aggressively in the main stream of international economic activities. Such activities have altered the resources of competitive advantage in the pulp and paper sector in the globalizing market. Availability of cost effective raw material, efficient energy management, access to sustainable technology for attaining cost competitiveness and compliance with ecological demands has constituted the critical success factor. Paper companies in India are sourcing wood from far flung areas, some are depending on bagasse, and some are sourcing residual wood etc. The Indian paper industry has no chalked down strategy for wood procurement or the sourcing of raw material. In the fast changing world, the regular degradation of resources and the rising environmental concerns has put pressure on the Industry. The industry as responsible citizens of the society has to comply with the water and energy norms and reduce its carbon footprints, which require huge investment. Speaking of pulp and paper in India the growth drivers are very strong driven by population, increase in urbanization, education, consumerism etc.

.

“I have only one advice for the traders and dealers they shouldn’t put restrictions on the quantity of paper to be sold rather increases it, thereby increasing their profit margins”

Mr. Ajay Goenka, Chairman & Managing Director, Rainbow Papers Ltd.

I started my journey as a paper trader in Ahmedabad and gradually ventured into the paper manufacturing with the capacity of 6,000 tons raising it to 305,000 tons per annum today. Earlier paper used to sell in a quota system i.e. whatever is manufactured is sold with no focus on the parameters like quality, GSM, brightness etc. Today the paper is being imported in India therefore we have to develop the competency level and give more focus to the customer requirements. The end user technology like printing press, converting units has touched the world class standards similarly we have to adopt best of technologies to fulfill their requirement and to be globally competitive. Manufactures and dealers have to go hand in hand if the industry has to prosper. I have only one advice for the traders and dealers they shouldn’t put restrictions on the quantity of paper to be sold rather increase it, thereby increasing their profit margins.

.

“The paper industry moves like the elephant strides not too fast, nor too slow”

Mr. OP Goyal, Whole Time Director, JK Paper Ltd.

Currently the demand of paper globally is down as compared to India, which is up and doing. Presently, our per capita consumption stands at 10 kg as compared to China, which is 45 kg so everyone should be positive, that the industry has a chance of phenomenal growth. The paper industry moves like the elephant strides not too fast, nor too slow. Likewise we don’t have too high margins or too low margins in the industry. With the stagnant growth of the economy paper industry will grow. And, an increase of 1 kg per capita will result in an increase production of 1 million tons. Indian paper industry has only one way to go that is upward because we have the second largest driving force with us i.e. our population. IT and service sector are on rise which is pushing the paper demand. The rise in organized retail sector is giving the positive vibes to the paper and board sector. Today the customer is aware and has more choices available for his varied demand. Import of paper is giving us tough competition so there is a need to strengthen our distribution channel so that we get the correct feedback from the market and can adapt according to that. In the last two years the paper margins have dropped form 20-25% to 10-12% and in some mills it has gone down to 6-7%. But still there is no mill, which has shut down due to inefficient demand. The margins have dropped due to some discrepancies in the distribution channel like the quantities may be sold at lower price anticipating the fear of slowdown. Technology up-gradations are not possible if the required margins are not being earned. Paper Industry is believed to be the forest destroyer and environmentally unpleasant which is not true, whatever trees we cut we sow more than that. Today the industry has to become cost competitive and for that investment in technology has to be there. New market needs to be explored for the products in future.

.

“Every now and then we talk about the shrinking of margins and economic slowdown my suggestion to you is to think positively and continue working because the best is yet to arrive.”

Mr. V. Subbiah, Vice President – Sales, The West Coast Paper Mills Ltd.

Everyday when we read newspapers the headlines that comes under our focus are manufacturing sector is going down, rainfall is inadequate, high inflation rate etc with this we believe that we are working in the world of uncertainties. But what we have to see is the certainties, the certainties in terms of advantage i.e. the population where the average age is between 25-30 years with large purchasing power and the availability of large work force. Every now and then we talk about the shrinking of margins and economic slowdown my suggestion to you is to think positively and continue working because the best is yet to arrive. Industry is playing its role very clear it is investing in state of art technology and providing you the best products benchmarking to the world class products. So, we request the dealers to play their necessary role. To uplift the industry the manufacture and the dealer has to play their respective role to attain the win-win situation.