In an increasingly water scarce world, water and wastewater management is a sine qua non for sustainable industrial practices, more so for the water intensive industry like pulp and paper. Paques recently, at a technical session, expounded how its range of biotechnological innovation may help the paper industry meet its wastewater management objectives.

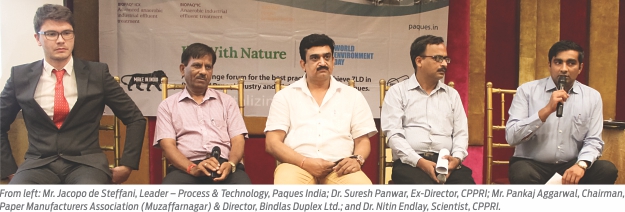

On the World Environment Day, Paques along with Muzaffarnagar paper mills organized a joint session to think about strategies and ways to contribute to a better and healthy environment to all. Moreover, the discussion revolved more around the water treatment remedies provided by Paques for the pulp and paper industry.

On the World Environment Day, Paques along with Muzaffarnagar paper mills organized a joint session to think about strategies and ways to contribute to a better and healthy environment to all. Moreover, the discussion revolved more around the water treatment remedies provided by Paques for the pulp and paper industry.

As the fresh water is increasingly becoming expensive and the pressure grows on the available water supplies due the rising world population and the climate changes, alternatives for the water balance in paper mills are eagerly sought after. Besides the higher costs for fresh water, the cost for discharging water has gone up. In the paper industry, recycling of water and wastewater is already common practice. The water is mostly reused for making paper pulp.

The Need to Come Together on Water Issues

Talking about recent innovations to drive away the challenges related to waste water, Mr. Suchit Dekivadia, Head of Sales & Marketing, Paques India. said, “The water stress in the world is increasing. By 2050, the world will face a serious water shortage. Simultaneously, the water demand is likely to surge with the growing population and energy demand. India is one of the strongest contenders in terms of energy demand. The growing demand can only be met through bio-fuel or renewable energy resources. There are total of 45 countries, which use 100 percent renewable resources for energy generation. Indian entrepreneurs should come together and accept the global innovations with implementing them as soon as possible.

Talking about recent innovations to drive away the challenges related to waste water, Mr. Suchit Dekivadia, Head of Sales & Marketing, Paques India. said, “The water stress in the world is increasing. By 2050, the world will face a serious water shortage. Simultaneously, the water demand is likely to surge with the growing population and energy demand. India is one of the strongest contenders in terms of energy demand. The growing demand can only be met through bio-fuel or renewable energy resources. There are total of 45 countries, which use 100 percent renewable resources for energy generation. Indian entrepreneurs should come together and accept the global innovations with implementing them as soon as possible.

“The pulp and paper industry has been a gross polluter. How to link the industry with nature is a great challenge. There are three things – technology, entrepreneurship and market. If we combine these three factors, we get innovation. At Paques, we do a lot of research to create that innovation.”

.

On behalf of the Indian pulp and paper industry and their increasing water concern, Mr. Pankaj Aggarwal, Chairman, Paper Manufacturers Association said, “We have 30 mills in Muzaffarnagar, out of which 24 are operational and remaining 6 are shut as of now. Earlier, there were fewer mills, the production was less, there were less pollution issues, and river water was in abundance. Increasing population and paper demand are creating increased wastewater incidences, and a result, the Kali Nadi in Muzaffarnagar has 90 percent of waste water. The river has no more remained a river as it has no fresh water. Industries should come together and work in favor for the environment and towards efficient wastewater management.

On behalf of the Indian pulp and paper industry and their increasing water concern, Mr. Pankaj Aggarwal, Chairman, Paper Manufacturers Association said, “We have 30 mills in Muzaffarnagar, out of which 24 are operational and remaining 6 are shut as of now. Earlier, there were fewer mills, the production was less, there were less pollution issues, and river water was in abundance. Increasing population and paper demand are creating increased wastewater incidences, and a result, the Kali Nadi in Muzaffarnagar has 90 percent of waste water. The river has no more remained a river as it has no fresh water. Industries should come together and work in favor for the environment and towards efficient wastewater management.

“Paques is one of the leading companies of the world and we have seen its installations worldwide. Paques provides biotechnological processes to purify water and gas streams for a wide range of applications. Their Anaerobic COD Removal technology for biogas is praiseworthy. We should use technologies like Paques has discovered.”

.

Increasing Significance of Anaerobic Processes

Dr. Nitin Endlay, Scientist, CPPRI (Saharanpur) emphasized the significance of anaerobic processes for wastewater treatment. He also suggested that pulp and paper mills must opt for such effluent treatment processes and renewable form of energy generation. He said, “Biogas production from the anaerobic reactor becomes increasingly important as a source of renewable energy. The time is apt for exploring the potential of this biological treatment system. The paper mill has two major concerns; first, the technology used in the mill is very costly; second, the after sale service is not looked properly. Paques installations to treat pulp and paper effluents has helped mills to reduce their cost through biological purification, physical separation and filtration and enables Paques to design, build and deliver a custom-made and cost-effective purification process. The best part is the IC reactors, which Paques have developed for industrial wastewater treatment; it enables the paper mills to comply with effluent discharge limits and produce biogas at the same time.

Dr. Nitin Endlay, Scientist, CPPRI (Saharanpur) emphasized the significance of anaerobic processes for wastewater treatment. He also suggested that pulp and paper mills must opt for such effluent treatment processes and renewable form of energy generation. He said, “Biogas production from the anaerobic reactor becomes increasingly important as a source of renewable energy. The time is apt for exploring the potential of this biological treatment system. The paper mill has two major concerns; first, the technology used in the mill is very costly; second, the after sale service is not looked properly. Paques installations to treat pulp and paper effluents has helped mills to reduce their cost through biological purification, physical separation and filtration and enables Paques to design, build and deliver a custom-made and cost-effective purification process. The best part is the IC reactors, which Paques have developed for industrial wastewater treatment; it enables the paper mills to comply with effluent discharge limits and produce biogas at the same time.

I am glad Paques associated itself with the paper mills through this program. This is a perfect way to celebrate the World’s Environment Day by having this useful deliberation on the best practices to achieve for the fiber based industries.”

Biotechnological Applications: A Surer Way to Water Sustainability

Mr. Jacopo De Steffani, Leader – Process & Technology Paques India, on the occasion, talking about Paques area of expertise, said, “Paques started its activities in India few years ago and our regional office is in Chennai. According to SAICA, Paques is the leading company in the field of anaerobic purification processes, both in the European as well as the world market. Paques technologies have proven themselves at the SAICA plants ever since 1992. Paques processes are stable, economically beneficial and environmentally friendly. The installations of Paque machines have increased to as much 70 percent in the past 5 years.

Mr. Jacopo De Steffani, Leader – Process & Technology Paques India, on the occasion, talking about Paques area of expertise, said, “Paques started its activities in India few years ago and our regional office is in Chennai. According to SAICA, Paques is the leading company in the field of anaerobic purification processes, both in the European as well as the world market. Paques technologies have proven themselves at the SAICA plants ever since 1992. Paques processes are stable, economically beneficial and environmentally friendly. The installations of Paque machines have increased to as much 70 percent in the past 5 years.

“The advantages of Paque installation are reliable operations through proven technology, space saving through clear designs, self regulating system with no odor emissions, production of green energy, the possibility of thermophile treatment, closed circuit, minimum sludge production, and saving in water and energy. Paques installation in the pulp and paper industry thereby ensures a high return on investment.”

Speaking on the water consumption pattern of different industries and how does it affects the quality of fresh water Mr. Steffani said, “With increasing awareness regarding water conservation, ever increasing pressure from government regulatory agencies and also due to increasing water scarcity many large industries have taken proactive steps like regular water auditing, technology modifications etc for reducing the water consumption.

“Pulp and paper sector is one of the water intensive industries. Apart from large volume of water that is consumed at each and every process stage of paper manufacturing, water is also required for utility sections like boilers and cogeneration plants to generate steam and power. Of late, water, the most sought out commodity, is depleting very fast and already started giving alarming signals in many parts of the country. The demand for water in a specific industry depends on the quality of paper and type of raw material used and the extent of recycling adopted in the mill. The most water consuming category is wood based and agro based integrated pulp and paper mills. So far, no water consumption standard has been set for water consumption by CPCB. Standards are prescribed in terms of wastewater discharge for different categories of pulp and paper industry.

“Due to stricter rules and regulations with regard to wastewater discharge, efficient water management has become essential to the pulp and paper industry. Paques’ technology results in low energy use and minimum sludge production, keeping operational costs low. Biogas production from the anaerobic reactor becomes increasingly important as a source of renewable energy. In most cases this even results in a positive energy balance for the entire purification plant.

Mr. Steffani explained how Paques biotechnological applications to purify water are the way to water efficient future. “Paques has integrated biological treatment in the closed water loop, resulting in significant improvements in the quality of the process water,” he said.

He further added, “In Anaerobic COD removal treatment, bacteria convert organic compounds (COD) to biogas in an environment without oxygen. Not only do the bacteria remove contaminating compounds from the effluent, thereby reducing discharge costs, they produce green energy at the same time.

“Another application, biogas desulpherisation, is important as biogas being an important source of sustainable energy, when produced through any form of anaerobic digestion, will be mostly polluted with hydrogen sulphide. Of the many methods available, THIOPAQ is the most elegant technology for the deep removal of hydrogen sulphide.

“Companies and municipalities have to remove nutrients from their effluents – such as nitrogen and phosphate – before they can reuse the water. There are also strict discharge limits on the nutrients levels that must be met. Paques has a number of technologies that can deal with these requirements. Paques ANAMMOX technology removes ammonia in a cost-effective and sustainable manner. The CIRCOX reactor is a very efficient aerobic system for the treatment of anaerobic effluents. It uses biofilm on a carrier material in an airlift reactor. The combination of PHOSPAQ and ANAMMOX recovers and removes phosphate and ammonia cost effectively and energy efficiently.”