Leading manufacturers of industrial pumps in India, Abirami Pumps, is planning to launch eco-friendly products to minimize its environmental impact, while integrating IoT and AI for real-time monitoring and data analytics. The company is also looking to expand its product lines to offer more tailored solutions to meet specific customer needs, leveraging feedback and market trends. This was shared by Mr. Guru Krishna, Chief Marketing Officer, Abirami Pumps, with Paper Mart in an exclusive interaction.

Paper Mart: Please share when and how you got into manufacturing pulp and paper equipment? Also elaborate the challenges you experienced in the initial stage and how you overcame them.

Guru Krishna: Being an upcoming pump manufacturer in the industry, pulp and paper machine manufacturing industries are the indigenous and prominent market for us. It is one of our missions and visions to get an unshakable place in these industries. We brought precise and personalized designs of pumps for the customers, critical and stringent quality checking system, service at its best, one stop shop for all the pumping requirements, and customer-friendly budget as our entry cards to get into the new manufacturing sectors. As we all know, dealing with the B2B sector is more challenging than the B2C sector as we have to be on par with updated cutting-edge technology, accurate application and sound engineering knowledge. While others took it as a challenge, we made it our advantage, riding on the back of a sound and untiring technical team.

PM: What types of paper grades and pulp types are your machines designed to handle?

GK: Abirami Pumps are designed to handle a wide range of paper grades and pulp types, such as graphic papers (coated and uncoated freesheet, newsprint and specialty printing papers); writing and printing papers (various grades for stationery, letterhead and other printed materials); packaging papers (linerboard, medium and corrugated papers); tissue papers (for facial, bathroom and industrial applications); and recycled kraft papers (processing post-consumer and post-industrial waste). In terms of pulp types, we can work with mechanical pulp (ideal for newsprint and some graphic papers); chemical pulp (bleached hardwood and softwood for high-quality writing and printing papers); recycled pulp (sourced from various paper products to promote sustainability); and bagasse pulp (sourced from sugarcane).

Abirami Pumps plans to launch eco-friendly products and utilize sustainable materials to minimize its environmental impact. We are looking forward to integrating IoT and AI for real-time monitoring and data analytics, allowing for predictive maintenance and optimized operations.

PM: What are the key features and specifications of your machinery? How do you compare them to similar products available in the market?

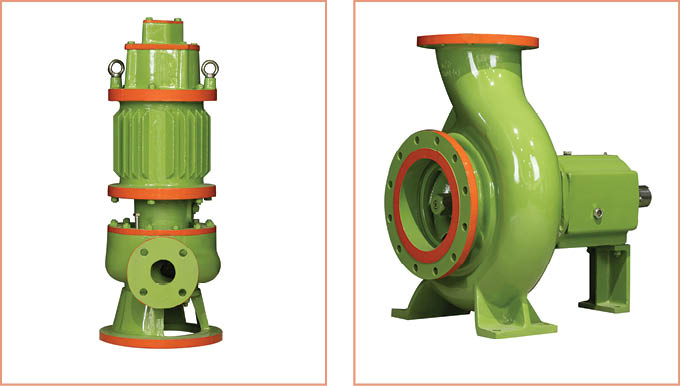

GK: Abirami Pumps comes with several key features, such as high efficiency, durability, triple bearing, smart technology, versatile compatibility, low maintenance, prompt service backup, and modular design. Our new-age energy pumps are highly-efficient and fit for productive operations. We have a complete range of centrifugal pumps to cover all applications in the industry. The products are fitted with heavy duty triple bearing design for trouble-free operation. The impeller triple locking system ensures no damage for the impeller due to back pressure. Abirami’s pumps are compatible with a wide range of fluids and capable of handling varying viscosities. The low-maintenance pumps come with best interchangeability, which ensures prompt service backup. The modular design allows continuous improvement without affecting fixing dimensions for an efficient and effective operation.

Abirami Pumps often outperform competitors in energy consumption while maintaining higher flow rates up to 7000M3/HR and operating pressure of 16 bar. Compared to similar models, our high-quality materials are more resistant to wear and corrosion, leading to longer life cycles. Our pumps are equipped with advanced monitoring systems for real-time performance tracking and diagnostics. These smart systems provide more comprehensive diagnostics compared to many standard options on the market. Our products are available in stainless steel, carbon steel, specialized alloys, Hastelloy steel, hard chrome steel, ss316, ss316L,w duplex SS A8903A, etc, in ANSI and DIN international standards.

Watch: In Pursuit of Lesser Water Footprint

PM: What is the expected lifespan of your equipment, and what kind of maintenance and after-sale supports are available?

GK: The expected lifespan of our equipment typically ranges around 10 years, depending on usage, operating conditions and maintenance practices. Our after-sale support includes technical support, spare parts availability, service contracts, upgrades and modifications, and training programs. Our technical support team is available via phone or email for troubleshooting and advice. We provide a range of spare parts readily available to minimize downtime. We also give options for extended service contracts that include regular maintenance and inspections.

PM: What kind of training and support do you offer for operators and maintenance personnel?

GK: For each and every project, our technical team visits the unit, both during pre and post erection stages to study the specific needs of a unit. The specifications and designs of the pumps are decided with mutual concurrence, involving a detailed discussion with the maintenance personnel and a complete session for operational guidelines to machine operators for a smooth and efficient operative system. Our scheduled maintenance services include parts replacement and system calibration on regular intervals. We organize training programs to help operators understand proper handling and maintenance procedures. Our comprehensive manuals and maintenance guides provide all guidance related to the equipment.

PM: What are the lead times for production and delivery? Do you offer customization options? What is your annual production capacity?

GK: Abirami Pumps supplies more than 750 models of pumps for industrial needs. We design and deliver tailor-made models on the basis of specific needs of the customers. After a deep observation of a customer’s needs, we propose the best efficient pump models to the customer representatives during the technical discussion. Our average annual production capacity is 5000 pumps.

PM: Discuss some of the major challenges you often experience in the pump manufacturing industry.

GK: The global market is highly competitive and one of the most pressing challenges is the influx of low-cost products from China. This creates immense pricing pressure, forcing many companies to either reduce their profit margins or find ways to reduce manufacturing costs without sacrificing on quality. Competing with these low-cost products also affects brand positioning, as customers may prioritize cheaper options over long-term quality and reliability, especially in price-sensitive markets. The global decline in the paper industry due to the rise of digital media, reduced paper consumption and increasing environmental concerns has directly affected the demand for pumps used in paper and pulp manufacturing. As a result, sectors that previously required significant pump investments are scaling back, leading to reduced sales opportunities in this niche.

In a market dominated by established global brands and cheaper alternatives, building a recognized and trusted brand worldwide is a formidable challenge. We are thriving in the industry by differentiating ourselves based on quality, innovation, sustainability and after-sales service. Expanding into new international markets involves facing tough competition from well-established local manufacturers. Local companies often have deep insights into regional needs, established distribution networks, and in some cases, government support or favorable trade policies. To enter these markets, we are trying to navigate different regulatory environments, local content requirements, and cultural nuances.

All these challenges are met and overcome by our strategic planning, innovation and resource management to maintain competitiveness in an evolving global market.

Also Read: ST Macchine Unveils Innovative Breast Roll Shaker

PM: How important is sustainability to you? Please discuss how it is ensured in your manufacturing process.

GK: In the paper industry, sustainability is the power and a challenge as well. A well-netted and well-spread industrial sector like pulp and paper industry will not vanish at any cost. Alternatives to assure sustainability are always available at the cost of upcoming technology and embracing the new system. We are thriving to sustain and will do so by adopting the same.

PM: What policy intervention would you like to see in place so that India produces more pulp and paper equipment manufacturers?

GK: We suggest establishing tax incentives or grants for companies investing in research and development. It will encourage innovation in equipment design and efficiency and foster a competitive local market. The government should invest in industrial clusters and dedicated parks for pulp and paper equipment manufacturers, providing them with the necessary infrastructure, such as power, water, and transportation. Besides, it can facilitate partnerships between manufacturers and research institutions for knowledge sharing and innovation, particularly in sustainable practices & technology. Supporting the initiatives that promote the use of locally-manufactured equipment through government procurement policies will ensure a stable market for domestic manufacturers.

Abirami Pumps often outperform competitors in energy consumption while maintaining higher flow rates up to 7000 M3/HR and operating pressure of 16 bar.

PM: Where do you see yourself in five years? What innovations are you planning to launch in future?

GK: In the next five years, Abirami Pumps envisions itself as a leader in the industry, driven by innovation and sustainability. Our new production facility will play a crucial role in this vision, enabling us to enhance our manufacturing capabilities and efficiency. We plan to implement state-of-the-art automation technologies to streamline production processes, reduce labor costs and improve precision. We are adopting complete systematization for our processes to reduce the production cost and increase the efficiency of our workforce. We can achieve maximum production with minimum expenses to meet the market demand.

Abirami Pumps plans to launch eco-friendly products and utilize sustainable materials to minimize its environmental impact. We are looking forward to integrating IoT and AI for real-time monitoring and data analytics, allowing for predictive maintenance and optimized operations. We are also looking to expand our product lines to offer more tailored solutions that meet specific customer needs, leveraging feedback and market trends. Developing equipment that consumes less energy while maintaining high performance is further on the cards, contributing to our commitment to sustainability. By establishing a new facility and focusing on these innovations, we aim to enhance our competitive edge and better serve our customers in a rapidly-evolving market.