Abirami Pumps has introduced several advanced, energy-efficient pump models, specifically engineered for medium-consistency stock applications and effluent treatment plants (ETPs). In an exclusive interview with Paper Mart, Mr. Guru Krishna, Chief Marketing Officer, Abirami Pumps, discussed how these advanced pumps effectively bridge critical gaps in the pulp and paper industry, tackling challenges such as high power consumption, frequent breakdowns, and poor corrosion resistance, particularly in mills that process recycled or chemically treated pulp. He also highlighted the company’s close collaboration with Original Equipment Manufacturers (OEMs) and mill engineers to ensure these pumps are equipped for remote monitoring and seamless digital upgrades.

Paper Mart: Could you explain your company’s key offerings and their relevance to the Indian pulp and paper industry’s dynamic needs?

Guru Krishna: Abirami Pumps is a specialized manufacturer and exporter of industrial pumps designed to handle the full spectrum of applications in the pulp and paper industry.

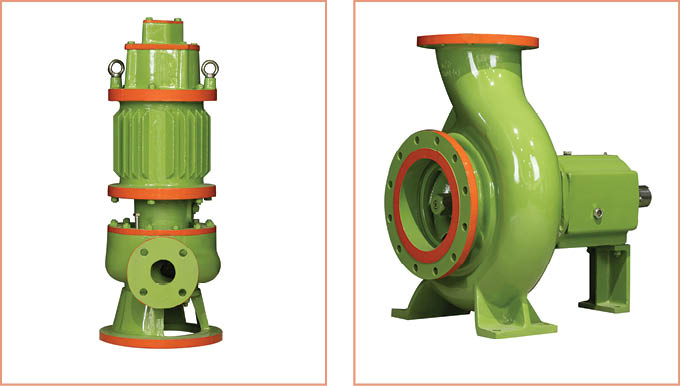

Our product portfolio includes pulp stock pumps (for high, medium, and low-consistency pulp), process pumps (handling white water, black liquor, and various chemical solutions), fan pumps, refiner feed pumps, vertical high pressure pumps, horizontal high pressure pumps, submersible sludge and slurry pumps, cantilever pumps, chemical dosing and coating pumps, effluent and water handling pumps, vacuum and dewatering pumps and custom and energy-efficient pumping systems.

These products are developed to meet the evolving needs of Indian mills, such as increasing demand for recycled paper, the rise of packaging grades, and the urgent push toward cost-efficiency and environmental compliance.

Watch: In Pursuit of Lesser Water Footprint

PM: Have you introduced any new products, upgrades, or solutions specifically for Indian paper mills? What gap were they trying to fill?

GK: We’ve introduced several upgraded energy-efficient pump models over the last few years, specifically tailored for medium-consistency stock applications and effluent treatment plants (ETPs). These upgrades address critical gaps such as high power consumption in outdated pump systems, frequent breakdowns due to abrasive slurry or poor-quality water, and inadequate corrosion resistance, especially in mills processing recycled or chemically treated pulp.

We’ve also added modular designs for easier maintenance and retrofit compatibility with existing systems which is a key for small and mid-sized mills looking to modernize gradually.

PM: What are the typical technological and operational issues in Indian mills, and how do you address them?

GK: The common challenges faced by Indian mills include inconsistent raw material quality, high-downtime due to equipment wear, poor energy efficiency, and limited automation or monitoring.

Abirami Pumps addresses these challenges by offering rugged pump designs with wear-resistant materials for abrasive and fibrous media. We also provide energy-efficient top quality pumps, supporting mills with custom engineering services to optimize selection and layout.

We work with Original Equipment Manufacturers (OEMs) and mill engineers to enable remote monitoring readiness, where digital upgrades are in place.

We design pumps that are automation-ready and can be integrated with flow, vibration, and temperature sensors, making it easier for mills to adopt smart technologies step by step.

PM: How do your solutions help mills reduce water and energy consumption, emissions, or chemical usage? Can you share a recent case study?

GK: Our pumps are engineered with high-efficiency hydraulics, helping mills reduce energy consumption by 10–20% depending on the application. In addition, accurate flow control in our chemical dosing and white water systems ensures optimal chemical usage and reduced wastage.

Case Study: In 2024, we partnered with a mid-sized kraft paper mill in Tamil Nadu to replace their old effluent recirculation pumps with Abirami Pump’s high efficiency models. The result leads to reduction in power usage, lower downtime and improved flow consistency, helping the mill comply with Central Pollution Control Board’s waste water discharge norms.

PM: To what extent have Indian mills integrated smart sensors, automation, and AI systems? What are the key enablers or barriers?

GK: Adoption of advanced technology (integrated smart sensors, automation, and AI systems) in paper mills is gradual but growing, especially in large and modernized mills. The key enablers include rising energy and water cost, government mandates on compliance, and a generational shift in the mill management mindset. Further, barriers for technology integration include high upfront cost of digital systems, limited technical support and training and concerns around ROI for small and medium mills.

We support this shift by designing pumps that are automation-ready and can be integrated with flow, vibration, and temperature sensors, making it easier for mills to adopt smart technologies step by step.

PM: How do you balance performance and cost, especially for small and mid-sized mills?

GK: Our philosophy at Abirami Pumps is to deliver ‘Ultimate destination for all liquid handling.’ We offer tiered product lines—from standard pumps to high-efficiency premium models—so mills can choose based on budget and its priority.

We focus on local sourcing, and in-house design and testing, reducing manufacturing costs without compromising quality.

Our modular and retrofit-friendly designs enable mills to upgrade selectively rather than overhaul entire systems. We provide ‘fit it and forget it’ type of technologies. This approach helps us support both large mills and SMEs by staying competitive and compliant.

PM: Can your technology help bring stability to mill operations amid raw material and quality variability?

GK: Our pumps are designed for heavy-duty process tolerance, especially when dealing with variable consistency in recycled fiber, and in the presence of contaminants like sand, plastics, and pins.

Our new-age, energy-efficient pumps are designed to ensure highly-efficient and productive operations across the industry. Offering a complete range of centrifugal pumps to cover all applications, these pumps feature a heavy-duty triple bearing design for trouble-free performance and an impeller triple locking system that prevents damage from back pressure.

With high mechanical reliability, improved metallurgy, and an environmentally friendly, maintenance-free, and noise-free build, they combine robust functionality with aesthetic appeal. These pumps also offer low maintenance with best interchangeability, economic pricing, and the shortest delivery period.

In addition, our service teams conduct energy audits to recommend flow and pressure stabilization strategies, helping mills achieve consistent output even under fluctuating conditions and improve overall mill efficiency.

PM: Are you investing in ‘Make-in-India’ or localization efforts in manufacturing or customization?

GK: Abirami Pumps is a proud ‘Make-in-India’ brand, with our entire manufacturing, R&D, and testing operations based in India. We maintain a 100% in-house production facility and invest in localized supply chains to minimize lead times and costs.

By offering customization services tailored to regional water quality, pulp types, and mill sizes, we ensure our solutions meet diverse operational needs. Our teams also undertake energy audits for pumps and their systems to drive efficiency.

Additionally, we actively contribute to skill development and generate employment in local communities. This strong foundation not only enables us to serve Indian customers more effectively but also enhances our global competitiveness.

Also Read: Lineomatic’s Innovation in Paper Converting Machinery Aiding Import Substitution

PM: What innovations or technological shifts do you foresee in the Indian paper industry over the next 3–5 years?

GK: Looking ahead, we anticipate several key trends shaping the industry. These include increased automation and the integration of AI in stock preparation and chemical dosing processes, along with a broader adoption of recycled fiber and advanced fiber treatment technologies.

We also foresee a wider implementation of Zero Liquid Discharge (ZLD) and circular water systems. Additionally, the use of hybrid or solar-powered auxiliary equipment, particularly in water and effluent handling, is expected to grow.

Further, decentralized smart monitoring solutions of pumps and motors, enable predictive maintenance and enhance overall mill operations. Abirami Pumps is actively investing in digital compatibility, sustainable designs, and high-efficiency models to stay ahead of the curve and continuously supports Indian mills in their modernization journey.

We focus on local sourcing, and in-house design and testing, reducing manufacturing costs without compromising quality. Our modular and retrofit-friendly designs help mills to upgrade selectively rather than overhaul entire systems.