With its new facility taking shape in Visakhapatnam, Axchem Solutions India Private Limited aims to address several key challenges faced by Indian paper manufacturers, from raw material variability to cost pressures, efficiency and sustainability requirements. Mr. Rajesh Chhabra, Managing Director, Axchem Solutions India Private Limited, said during an exclusive chat with Paper Mart that the company further plans to provide innovative chemical solutions for packaging, tissue and specialty paper segments, aligning with market needs and sustainability goals.

Paper Mart: Congratulations on your new facility at Visakhapatnam. How will this manufacturing hub address the multiple production challenges facing Indian paper manufacturers?

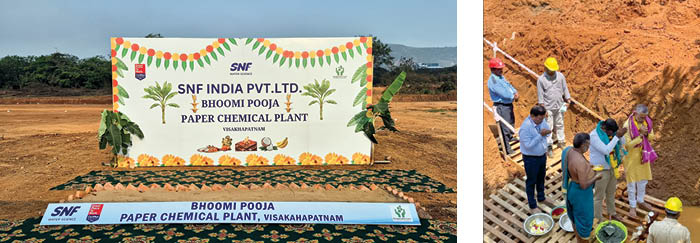

Rajesh Chhabra: The Visakhapatnam facility, which represents our largest investment in the Indian market till date, is strategically designed to address several key challenges faced by Indian paper manufacturers, from raw material variability to cost pressures and sustainability requirements.

Axchem Solutions India Private Limited provides advanced chemical solutions that enhance the consistency and quality of raw materials, ensuring stable production processes. No matter the raw material you choose for your production, we cover through our broad product range. Being locally produced in Visakhapatnam, these chemicals help mitigate supply chain disruptions and reduce dependency on imports.

By employing efficient production techniques and achieving economies of scale, the company can reduce manufacturing costs, making paper production more economically viable. Our retention and drainage aids alone can help achieve energy cost savings and increase production. Our scale inhibitor reduces scale build-up and downtime plus improves process control and increases the output produced. Axchem Solutions India offers eco-friendly products and implements advanced waste management systems, enabling paper manufacturers to meet stringent environmental standards and regulations. Through these initiatives, our Visakhapatnam facility plays a crucial role in improving efficiency, reducing costs and promoting sustainability within the Indian paper industry.

PM: Is Axchem Solutions India planning any specific chemical formulation to address the challenges of the heterogeneous raw material mix used by Indian paper manufacturers?

RC: The Indian paper manufacturers process a diverse fiber basket, including hardwood, eucalyptus, bamboo and agricultural residues, which is quite different from their European counterparts, who primarily use softwood. We offer a broad range of specialized products to address these challenges. We understand the manufacturing process and the heterogenous raw material mix used by a paper manufacturer through our site executives and accordingly, our application team tailors the specific chemical apt for our customer. For example, AXFLOC® is a product segment that has a diverse range of flocculation products suitable for the diverse fibre mix used by Indian paper mills. Our technologies are developed with different concentrations and chemical combinations to fit all paper machine conditions. These tailored chemical solutions from Axchem Solutions India help paper manufacturers manage the complexities of their raw material mix, ensuring high-quality, cost-effective, and sustainable paper production.

Watch: In Pursuit of Lesser Water Footprint

PM: Which specific product segments does Axchem Solutions India intend to prioritize at the Visakhapatnam facility? What market factors will drive these priorities?

RC: Paper manufacturers require various chemical categories across their production processes, including sizing agents, retention aids, specialized coatings and other additives. We will prioritize multiple product ranges in our plants. Along with the existing facility, this new line will bring revolution in the Indian paper industry. We have currently announced the first phase of development and will expand the facility further in coming years. This expansion covers mainly the latest range of strength additives, along with a full range of tissue coating chemicals, AKD, defoamers, drainage aids, fixing agents and deposit control additives like MB, scale, stickies/pitch, etc.

PM: The Axchem Group has developed chemical solutions for paper manufacturing globally. How will technology transfer between your global R&D hubs and the new Indian facility address local challenges like energy efficiency, high-temperature processing, and water usage?

RC: The Axchem Group will leverage its global R&D expertise to address local challenges at its new Indian facility by implementing advanced chemical formulations like AXFLOC® to reduce energy consumption and with products like AXCONTROL® to improve efficiency and safety in high-temperature operations. The company will adapt innovative water treatment technologies such as AXPERSE® to optimize water usage and reduce waste.

PM: What specific water conservation technologies will Axchem Solutions India introduce in India to reduce water consumption in paper mills?

RC: Water consumption in Indian paper mills has historically been higher than global averages, though recent initiatives have reduced it to approximately 40–50 cubic litre/tonne. European mills often achieve consumption rates as low as 10–30 cubic litre/tonne. In order to bridge this gap, we plan to introduce advanced flocculation and coagulation agents in Indian paper mills, which are highly efficient and enhance the removal of suspended solids from process water, allowing for better water recycling and reuse. Our customized chemical programs optimize the use of water in specific mill processes, while high-efficiency defoamers and deaerators optimize air and foam removal from water. The innovative dispersing agents prevent scale formation, which further reduce the usage of water in paper mills for non-value-added activities, while pitch solution reduces the contaminants and improves the removal of pulp contaminants for optimized washing water. With the help of these technologies, the Indian paper mills will be able to reduce their water usage and align with best global practices.

PM: Is Axchem Solutions India looking forward to pursuing deeper partnerships or alternative collaboration models with Indian companies?

RC: Axchem Solutions India will pursue deeper partnerships with Indian producers to leverage the full range of our services alongside customized service arrangements tailored to the specific needs of Indian paper producers. We are completing our basket with a comprehensive range of products. At the same time, our equipment division is working towards introducing a cloud-based program to get real time data of all applications and their control. We follow a comprehensive approach of not only providing the right chemistry, but also lending the professional engineering to apply it, including equipment, technical support and analysis capabilities.

PM: Indian paper producers typically operate on margins 3-4 percent lower than global averages. How does your pricing strategy balance performance benefits against the cost sensitivity that defines this market?

RC: Axchem Solutions India offers products at competitive prices, ensuring affordability without compromising on quality. We produce locally and minimise dependency on import of paper chemicals, thus helping the industry to improve their bottom line. Our solutions improve retention, drainage, strength, and contaminant control, which not only enhance paper properties, but also results in backend improvement in sludge dewatering, effluent colour reduction and control in TSS, BOD & COD. This lowers operational costs and increases productivity. By incorporating eco-friendly and efficient chemical formulations, we help reduce compliance costs and enhance sustainability.

PM: What specific recruitment and training initiatives will Axchem Solutions India implement to build a strong technical service team in India?

RC: Since the specialized chemical engineering talent pool in India’s paper sector is very limited, Axchem Solutions India plans to build one of the latest paper labs in the country, to impart technical training over the use of chemicals for different applications and for the development of customized solutions for specific customers based on their needs. We plan to tie up with universities focused on pulp & paper courses to assign developmental projects and provide practical knowledge to students of these varsities. Our staff is diligently following the best practices and continuously improving our processes and products, preparing them to tackle the challenges faced by the Indian paper manufacturing industry head on.

Also Read: Turning the Tide: The Push for Water Circularity in Paper Mills

PM: How do you plan to adapt your manufacturing processes in the upcoming facility to align with the rising compliance costs and evolving water laws in India, while maintaining high product performance?

RC: The compliance costs for chemical manufacturers have risen in India, owing to the recent amendments to the Water (Prevention and Control of Pollution) Act, 1974, and tightening of effluent discharge standards. In order to reduce water usage and for advanced waste management in our facility, we are implementing cutting-edge technologies and enhancing our manufacturing processes, equipping them to meet the evolving regulatory requirements. We are focusing on recycling and reusing the water inside the plant. Our robust systems will continuously monitor regulatory compliance. We are also developing products that require less water and generate fewer pollutants, including organic coagulants for COD reduction, and high molecular weight & low molecular weight compounds for effective BOD reduction.

PM: Which specific market segments is Axchem Solutions India targeting for its growth?

RC: With India’s paper production capacity projected to reach 30 million tons by 2030 from about 25 million tons today, Axchem Solutions India plans to provide innovative and tailormade solutions for packaging, tissue and specialty papers, aligning with market needs. With the surge in demand for packaging for e-commerce, we will prioritize products like AXFLOC®, AXFIX® for improved retention and dewatering, and AXSTRENGTH® for enhanced paper quality, production and strength in the packaging sector. We envision huge growth in niche markets of specialty papers. We will also focus on products like AXCOATING® TISSUE to optimize quality and efficiency in tissue paper production.

We plan to introduce advanced flocculation and coagulation agents in Indian paper mills. These agents are highly efficient and enhance the removal of suspended solids from process water, enabling improved water recycling and reuse. This initiative aims to bridge the gap in water consumption rates between Indian mills and the global average.