Like all innovations that mark a “before” and “after”, Constellation stems from the perfect mix of intuition, creativity and design, an endeavor undertaken with perseverance by the extraordinary engineers of the Fabio Perini’s R&D department.

Rewinders are an essential part of any tissue converting operation, and their performance largely drives production success. The current 3- and 4-roll rewinder configurations are both popular in the field.

However, as converters gain comparative experience they are discovering significant advantages in using 4-roll rewinders, particularly as it relates to improved roll control and exceptional winding geometry design.

Let’s briefly explore some of the benefits a 4-roll rewinder could provide to your operation.

Simple, Full Traction Control

The control process with 4-roll rewinders, like that found in Fabio Perini’s Constellation™ is smooth and stable due to:

- The introduction of first three, then four roller surfaces in the rewinding cycle to weight-support and control logs throughout winding. There are simply fewer parameters for machine operators to monitor or adjust as compared to 3-roll rewinders.

- The availability of up to five driving surfaces ensures low-torque/low-pressure winding and nearly perfect, uniform roll profiles from beginning to end. The triangular winding geometry of 3-roll rewinders generally cannot offer this consistency.

Constellation™ from Fabio Perini is the preferred choice in rewinders. Its 4-roll technology, which includes model S8 for high speeds (up to 800 mpm) and S6 for mid-level production (600 mpm).

Enhanced Product Quality and Production Efficiencies

With 3-roll rewinding, the core is shot against two winding rolls then squeezed between them to be moved into the rewinding zone — all while the third roll is in the upper position managing the previous roll expulsion. This results in:

- Tissue being wound very densely near the core

- Log instability

- The need for continuous adjustments to accommodate changes in paper characteristics and embossing

In 4-roll rewinding with Constellation™, the fourth roll accompanies the core to the rewinding zone with gentle control and starts the rewinding with three rolls instead of two in order to:

- Provide a uniform, near-perfect winding profile from the very beginning

- Increase line speed significantly for soft products because of rewinding stability (and inclusion of Punzoncini in the case of Constellation™)

- Eliminate log vibration

Statistics bear out the comparison. Recent feedback from Constellation™ customers reflects the positive impact of the transition — 64% report being extremely satisfied with product quality! Plus, more than 100 lines have been sold worldwide since the technology’s launch in 2015.

Four-roll technology is proving essential for overall equipment efficiency (OEE). Half of our Constellation™ customers, including U.S.-based Cardinal Tissue, are extremely satisfied with OEE improvements resulting from 4-roll rewinder capabilities surrounding.

Simplified Line Operations

Four-roll technology is proving essential for overall equipment efficiency (OEE). Half of our Constellation™ customers, including U.S.-based Cardinal Tissue, are extremely satisfied with OEE improvements resulting from 4-roll rewinder capabilities surrounding:

- Elimination of the most critical setup parameters required by 3-roll winding which makes the process more intuitive, simplifies product switching, and automates product replication across machines — a significant help to less-experienced operators

- Absorption of certain variations in paper characteristics and fiber mixes due to superior winding profile, strength retention, and high-speed bulk development

- Better management of desheeting and long-term product development because of the widest operating window and bulk development capability in the industry

- Reductions in per-roll fiber cost

Log Growth Mapping

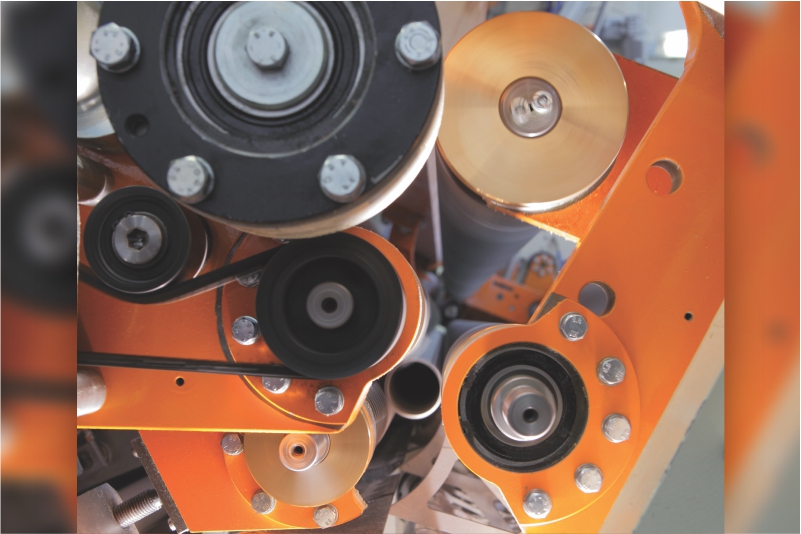

Constellation™ offers virtual positioning of the log in the rewinder so the winding rolls, controlled by servomotors, can be precisely placed around the log at any time. This ensures perfect and delicate rewinding control. Since the rotation of each roll is controlled by an independent motor, the speed balance between them is soft with little variation.

On the other hand, 3-roll technology is subject to sudden acceleration that shocks both the tissue and the machine. Continuous tissue and equipment adjustments are required as paper characteristics and embossing change.

Increased Product Differentiation, Decreased Costs

• With Constellation™, the four winding rolls:

- Produce larger diameter logs with the same amount of paper

- Require less paper to achieve equivalent roll diameters

- Use more economical base sheets while maintaining desired product attributes

- Allow for higher roll softness and “spontaneous” log growth that ensures higher production consistency and maximum embossing yield at every point on the roll

Why Use a 4-roll Rewinder?

Constellation™ from Fabio Perini is the preferred choice in rewinders. Its 4-roll technology, which includes model S8 for high speeds (up to 800 mpm) and S6 for mid-level production (600 mpm), radically changes the concept of rewinding in several essential ways:

- Perfect rolls from first to last sheet: Patented by Fabio Perini S.p.A., Constellation™ technology ensures unprecedented winding quality as four mobile rolls with independent drives consistently and uniformly accompany logs from the first sheet to the last.

- No obstacles to production: Constellation™ provides four points of contact for greater log control and faster winding. With a Punzoncini system to handle structured webs and soft roll production, speeds up to 800 m/minute are possible.

- Absolute quality: Gentle winding preserves decor and finished product quality. Rolls also have greater bulk, even when using less, lower-quality, or lower basis-weight paper.

- Intuitive interface with easy HMI: The elimination of critical and complex parameters combined with multi-functional, image-based HMI control panels allow less-experienced operators to autonomously “pilot” the rewinder.

- Improved effectiveness: Constellation™ has an extensive library of preset and custom combinations that fosters quick and simple product changes — enabling consistent quality when replicating the same product on different machines, in different plants, and over different time periods.

- Safe technology: Most operations are performed directly from the HMI control panel, limiting the need for operators to access the machine. In the unlikely event an operator needs to physically engage with the equipment, Constellation construction is mechanically simplified to minimize any safety risk.

Tissue converters that choose Constellation™ from Fabio Perini are gaining substantial competitive and operational advantages — from advanced 4-roll rewinder technology to a network of expert support and service.