The completion of PM6 is set to double the company’s production capacity at Sapphire Mill site to over 64,000 tonnes annually, allowing them to meet the growing demand for its tissue paper parent reel products.

Oct 10, 2025

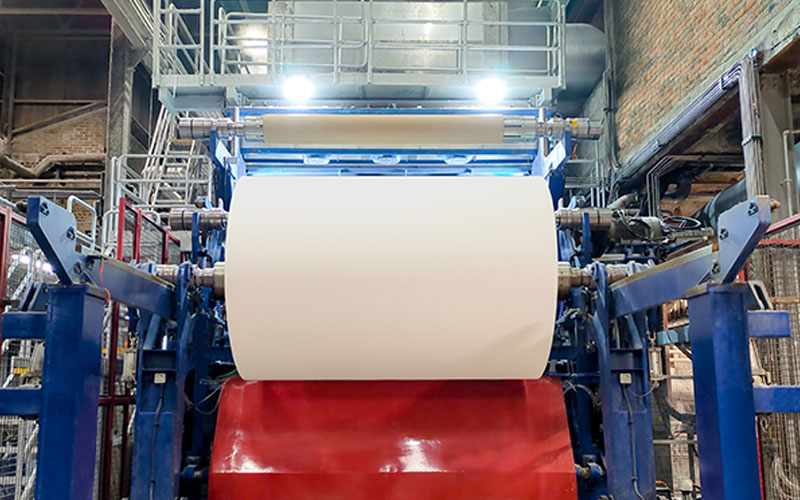

Fourstones has announced its new paper machine PM6 is commissioned and operational. Built at the Sapphire Mill site in Scotland, the new machine follows months of dedication, from planning and construction to safety measures and testing.

Watch: In Pursuit of Lesser Water Footprint

The purpose of PM6 is to manufacture high-quality tissue paper parent reels for the UK paper converting market. This new machine also strengthens the resilience of the finished goods operations by improving the resilience and integration of our internal supply chain.

PM6 will enable shorter lead times for UK converters while ensuring consistent quality and reliability in every roll. By providing a strong domestic alternative to imported paper, PM6 supports the reduction of transport-related carbon emissions per tonne and contributes to the sector’s wider sustainability goals.

PM6 is equipped with advanced technology, including a Crescent Former, a fabricated steel Yankee cylinder, and a high-temperature drying hood. With a trimmed width of 2.75 m and an operating speed of 1,700 m/min, PM6 has been designed to combine high capacity with consistent, high-quality output.

Also Read: UPM Ends Paper Production in Kaukas, Finland

The completion of PM6 is set to double the company’s production capacity at Sapphire Mill site to over 64,000 tonnes annually, allowing them to meet the growing demand for its products.