Smurfit Kappa and Bimbo held an Innovation Day to fully understand Bimbo’s goals and through a collaborative process, developed a corrugated solution.

Bimbo, the world’s largest baker faced three challenges in their efforts to streamline their supply chain. 1. Improve the plastic tray return cycle to reduce production line stoppage time. 2. Improve product protection during long-distance transport. 3. Meet retailer demand to move to shelf ready packaging.

Bimbo, the world’s largest baker faced three challenges in their efforts to streamline their supply chain. 1. Improve the plastic tray return cycle to reduce production line stoppage time. 2. Improve product protection during long-distance transport. 3. Meet retailer demand to move to shelf ready packaging.

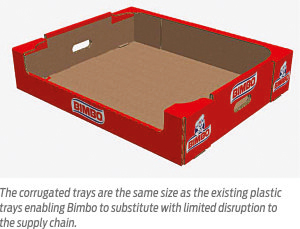

Smurfit Kappa and Bimbo held an Innovation Day to fully understand Bimbo’s goals and through a collaborative process, developed a corrugated solution. The corrugated trays are the same size as the existing plastic trays enabling Bimbo to substitute with limited disruption to the supply chain. Bimbo’s new trays are also fully branded to enhance product visibility on the shelf.

The corrugated trays resulted in a 95% reduction in warehouse space so that Bimbo can respond quickly to peaks in demand while saving 50% in shipping and distribution costs. The new design also functions as shelf-ready packaging enabling Bimbo to apply branding and promotion messages quickly and easily.