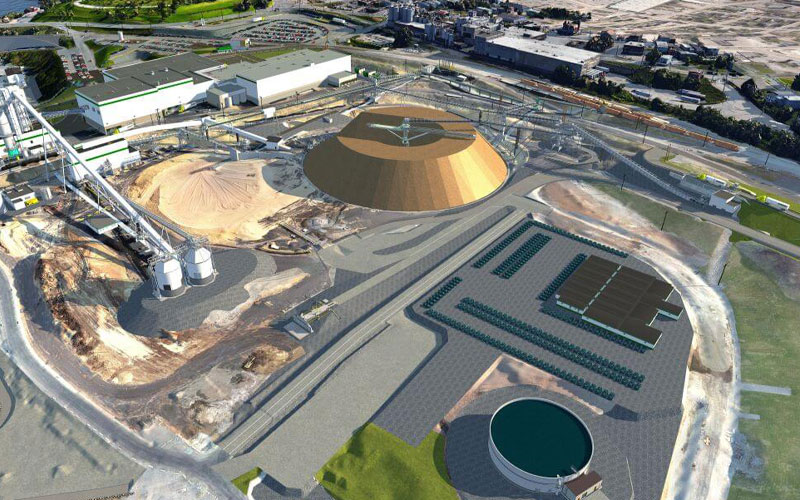

The upgrade includes installation of the world’s largest automated stacker reclaimer, which will first stack the woodchips into a large pile and the reclaimer will later remove them for use in the kraft pulp making process.

Apr 9, 2024

The woodyard at Irving Pulp & Paper in West Saint John, New Brunswick is reaching new heights in technological advancement with a project worth USD 110 million to update how the site receives and stores woodchips.

Currently underway, the upgrade includes the installation of a new automated stacker reclaimer that is the largest of its kind in the world. This technology “stacks” woodchips into one large pile, while the reclaimer function removes the woodchips from the pile to be used in the kraft pulp making process.

This automated machinery will improve safety at the site, while enhancing quality and reliability.

Watch: Top Paper Companies 2023

The woodyard project, which is anticipated to reach completion in 2025, will employ an additional 150 skilled workers from 26 local contractor companies.

“This capital investment strengthens our commitment to the local community and bolsters economic stability. Since the project began, we’ve not only employed local contractors, but also greatly improved the safety of our employees and reliability of the mill that will meet the needs of our customers for generations to come,” said Mark Mosher, vice president of the Pulp & Paper Division.

Also Read: UPM Raflatac Opens New Slitting and Distribution Terminal in India

The site of Irving Pulp & Paper (Union Point), has been used for mill operations since the 1800s. Irving Pulp & Paper has undergone many capital investments over the years, most recently a new USD 300 million state-of-the-art pulp dryer. The mill now directly employs over 380 full-time employees and over 85 local contractors.