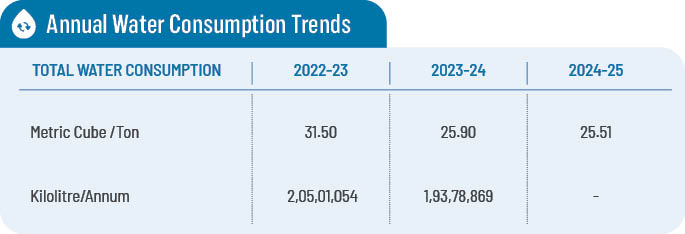

In its pursuit of water conservation and sustainability, JK Paper Limited has turned innovation into impact. By investing in forward-thinking technologies such as tertiary clarifiers, Venturi-type steam traps, disc filters, and advanced effluent treatment systems, the company has reduced its freshwater consumption from 31.50 m³/tonne in 2022–23 to 25.51 m³/tonne in 2024–25—achieving a notable reduction of over 19% in just two years.

JK Paper Limited, renowned not only for its quality paper and paper products but also for its steadfast commitment to sustainability and environmental stewardship, has a central focus on water conservation and treatment, placing it at the core of its operational and environmental strategies.

The mill has continuously worked on optimizing process parameters through advanced automation technologies and data-driven systems ensuring operational efficiency, tighter process control, and more effective resource management across its manufacturing units. The company aims to minimise fiber loss and freshwater consumption in order to become one of the lowest per-unit water consumption mills within India’s integrated pulp and paper sector.

Through sustained efforts and strategic investments in water management, the company has significantly reduced its specific water consumption—from 31.50 m³/tonne in 2022–23 to 25.51 m³/tonne in 2024–25—demonstrating its operational efficiency and resource conservation.

Watch: In Pursuit of Lesser Water Footprint

Water Optimisation Initiatives Unit

JKPM, Rayagada

This unit has consistently focused on enhancing environmental performance by reducing the consumption of key resources such as water, steam, coal, and power per tonne of paper produced. The unit has reduced its water consumption through its water-saving schemes.

Notable advancements include the commissioning of a tertiary clarifier to reduce the color of treated effluents and the replacement of conventional disc-type steam traps with venturi-type traps, leading to improved steam efficiency. These traps do not contain or rely on moving parts thereby reducing failure rates and leading to longer operational life than mechanical steam traps.

Additionally, the unit has deployed an electro-static precipitator in all boilers, scrubbers, dust extraction system, dry fog system and bag filters, monitoring via AAQM stations; and the real-time data is transmitted to relevant Pollution Control Boards.

Unit CPM, Songadh

This unit has adopted a comprehensive approach to environmental sustainability by integrating advanced emission and wastewater control technologies into its operations.

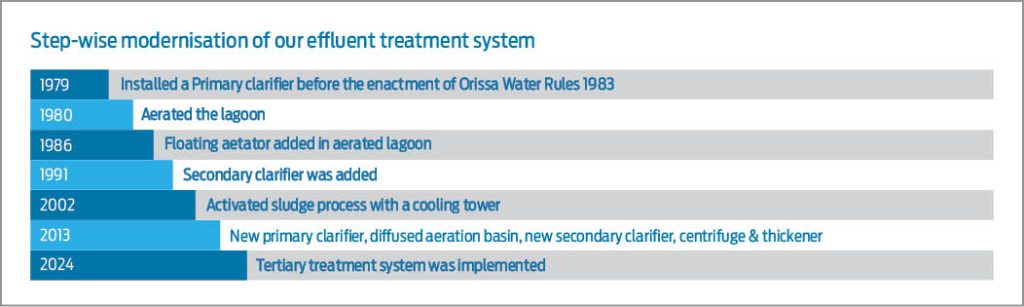

The CPM unit implemented water recycling and reuse systems, enabling treated water from various processes to be reintroduced into operations, thereby significantly reducing freshwater consumption and minimizing wastewater discharge. The primary sludge is recycled into low-grade paper, further supporting circular resource use. It has also enhanced its effluent treatment infrastructure with advanced technologies to ensure efficient treatment and safe disposal of wastewater generated during production.

The efficient water management practices further include both internal and external water audit to help optimize water use across the facility. A dedicated water audit team actively identifies areas of loss or inefficiency and introduces water-saving technologies such as low-flow fixtures and equipment, reinforcing the company’s commitment to responsible and sustainable water stewardship.

Unit SPM, Sirpur

This unit has undertaken a range of innovative and sustainable initiatives aimed at optimizing water resource efficiency and minimizing environmental impact. Waste reduction measures, such as the installation of disc filters in paper machines, have helped minimize fiber loss and reduce freshwater consumption. A high-pressure, high-efficiency fluidised bed combustion boiler has been commissioned to support cogenerated power.

On the water management front, the unit has enhanced its chemical efficiency by improving lime purity from 76% to 80%, reducing overall chemical consumption. These initiatives contributed to a substantial decrease in water consumption. Furthermore, a sewage treatment plant has been established for treating domestic effluents, with the treated water being utilized for green belt development.

The unit has achieved 100% compliance with all statutory requirements related to emissions and water discharge.

Natural Resource Management

In Tapi Gujarat, JK Paper has undertaken various initiatives like well renovation, solar-based mini lift irrigation and bori bandh to provide sustainable solutions and improve irrigation practices in the region. Over 386 acres of land has been irrigated through these water resource development projects. The company has also harvested 30.27 crore liters of water, benefiting 2,605 farmers, and has commissioned three solar-based irrigation schemes that benefited farmers across 34 acres of land.

As part of its commitment to water conservation and rural development, the company has renovated five check dams, enhancing water storage capacity by over 1.64 crore liters, which now supports irrigation for 62 acres of land and benefits more than 142 farmers.

In addition, the construction of 26 bori bunds in eight villages created a water storage potential of 1.22 crore liters, helping irrigate 145 acres and positively impacting 124 farmers. The company also developed 7 farm ponds across five villages, benefiting 18 households and enabling irrigation for 20 acres, with a cumulative storage capacity of 2.05 crore liters. Farm bunding structures were created over 51.70 acres in five villages, adding 70 lakh liters of storage capacity. Furthermore, 38 drain plugs were constructed, benefiting 16 farmers across eight acres with a storage capacity of 5.13 lakh liters. Deep continuous contour trenches were also developed in six villages, contributing a significant water storage capacity of 7.38 crore liters. Collectively, these initiatives have enhanced groundwater recharge, improved agricultural productivity, and strengthened climate resilience in local communities. In Rayagada, Odisha, the company installed a water tank to ensure access to safe and quality drinking water for the local community.

The company’s total water withdrawal decreased from 2,05,01,054 kilolitres in FY 2022–23 to 1,93,78,869 kilolitres in FY 2023–24, indicating a reduction of approximately 5.5%, compared to the previous year.

Certifications and Awards

JK Paper’s commitment to environmental stewardship has been recognized through prestigious accolades and certifications. The company received the CII National Award for Excellence in Water Management 2023 for both its JKPM and CPM units, highlighting its efforts in sustainable water use and conservation.

JK Paper holds the ISO 14001:2015 certification, which outlines the criteria for an effective Environmental Management System (EMS). This certification affirms the company’s systematic approach to managing environmental responsibilities, underscoring its contribution to sustainability and continual improvement in environmental performance.

Also Read: Naini Papers Minimizes Water Footprint With Membrane Technology

Conclusion

JK Paper has demonstrated a strong commitment to sustainable water management through measurable improvements in water efficiency across its operations. In FY 2023–24, the company’s total water withdrawal decreased from 2,05,01,054 kilolitres in FY 2022–23 to 1,93,78,869 kilolitres in FY 2023–24, indicating a reduction of approximately 5.5%, compared to the previous year.

Notably, water consumption per tonne of production decreased from 31.5 to 25.51 kilolitres, reflecting a significant enhancement in operational efficiency. The marginal improvement in water consumption per unit of revenue—both nominal and PPP-adjusted—further underscores the company’s focus on optimizing resource utilization. These results highlight the effectiveness of JK Paper’s targeted investments in water-saving technologies and process optimization, aligning with its broader sustainability goals.