JMC is actively partnering with leading automation providers to deliver integrated smart and sustainable solutions. The company emphasizes on modular, scalable, and easy-to-implement technologies to ensure that the paper mills in India and abroad can seamlessly adopt digitalization. In an exclusive interview with Paper Mart, Mr. Rajni Patel, CMD of JMC Paper Tech Private Limited, highlighted the company’s new facility in Mexico, which will serve as a dedicated R&D hub to rigorously test and refine JMC’s technological innovations under real-world scenarios. Looking ahead, the company is also set to launch proprietary AI tools that will empower customers with instant access to machine data and performance insights, further driving operational excellence.

Paper Mart: Could you explain JMC Paper Tech’s core offerings and their relevance to the Indian pulp and paper industry’s dynamic needs?

Rajni Patel: At JMC Paper Tech, we are a leading force in the pulp and paper machinery sector, specializing in the end-to-end delivery of sophisticated systems on an EPC (Engineering, Procurement, and Construction) basis. This comprehensive approach handles everything from the initial design and engineering to the meticulous manufacturing, supply, and final commissioning of complete pulp and paper mill setups.

Our extensive portfolio of key offerings is meticulously crafted to meet the diverse and dynamic needs of the Indian paper industry, as well as the global market. These include: full turnkey paper machine projects that deliver complete, operational paper machine lines that are ready for production, and minimize complexity for our clients; advanced stock preparation systems that are crucial for transforming raw materials into a suitable pulp slurry for papermaking. These systems are designed for optimal fiber treatment and cleanliness.

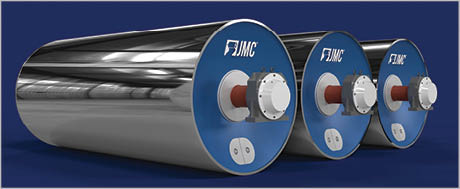

Our integrated pulp mills offers solutions for both agro-based pulp mills (utilizing sustainable agricultural residues like bagasse, wheat straw, etc.) and wood-based pulp mills, catering to various raw material availabilities and sustainability goals, and our critical auxiliary equipment extends our expertise to vital components that significantly impact our machine performance and paper quality, such as: headboxes-essential for uniformly distributing pulp slurry onto the forming wire; press sections- crucial for efficient dewatering, enhancing paper strength and reducing drying energy; steel dryers- engineered for superior heat transfer and energy efficiency in the drying process; high-speed rewinder systems- designed for precise and efficient winding of large paper rolls into consumer-ready smaller reels, optimizing production flow.

We cater to a broad spectrum of the Indian paper industry, from kraft paper producers (for packaging, corrugated boxes) to coated board manufacturers (for high-quality printing and packaging), tissue manufacturers (for sanitary products), and writing and printing paper manufacturers. Our solutions are specifically engineered to align with the evolving demands of these sectors, focusing on high-efficiency production, low resource consumption and easy adaptability to recycled and agro-based raw materials, supporting the industry’s shift towards more sustainable and locally sourced feedstocks.

Our capabilities are underpinned by robust in-house R&D, combined with extensive practical mill experience. This synergy allows us to develop and deliver equipment that is not only rugged and durable but also highly energy-efficient and easy to operate, specifically optimized for the unique operating conditions prevalent in Indian paper mills.

Watch: In Pursuit of Lesser Water Footprint

PM: In recent years, have you introduced any new products, upgrades, or solutions specifically designed for Indian paper mills? What gap in the market were they trying to fill?

RP: Innovation is at the core of our response to market needs. In recent years, JMC Paper Tech has introduced several cutting-edge products, upgrades, and solutions, meticulously tailored for both Indian and international paper mills, designed to address critical industry challenges.

The company has introduced complete agro-based and wood-based pulping equipment. These comprehensive systems fill the gap for mills looking to efficiently process diverse raw material sources, offering robust solutions for sustainable fiber sourcing.

The company also offers complete tissue machine production lines, catering to the growing tissue paper market with a strong focus on efficiency and quality.

JMC Paper Tech also possesses compact, high-speed paper machines, with Elite Pro Series, that are specifically engineered for medium-scale mills. These machines enable significant increase in production without necessitating major infrastructure overhauls. They address the demand for higher output in existing footprints.

The company also features 3D scanning for whole machines. This advanced scanning capability allows for highly accurate mill assessments and precise integration of new equipment, minimizing installation errors and downtime.

Additionally, the machinery company has complete stock preparation with JMC’s Fiber Pro Stock preparation lines. These groundbreaking systems are designed to enhance fiber treatment while simultaneously reducing chemical dependency and minimizing fiber damage. By improving pulp quality, they directly contribute to superior paper strength properties. This addresses inconsistencies in raw material processing and fiber quality.

The company has also introduced steel dryers to save energy. This advanced steel dryer technology significantly improves heat transfer efficiency in the drying section, leading to substantial energy (steam) savings – a critical cost and environmental benefit.

Further, the company has advanced components such as headboxes and advanced press sections

that have been specifically developed to achieve better formation (uniformity of the paper sheet)and more efficient dewatering (removal of water) in kraft and testliner applications. They tackle common pain points related to paper quality and energy consumption in these segments.

Finally, the company offers high-speed rewinder with a fully auto tension controller and regenerative breaking system that ensures precise tension control during rewinding, leading to perfectly wound reels, reduced waste, and improved operational efficiency, addressing issues of poor runnability and reel quality.

These new products and upgrades collectively address critical gaps such as inconsistent paper formation, poor machine runnability, and high steam and power consumption – all prevalent challenges in many Indian mills.

We anticipate the rise of modular, scalable, and cost-effective automation solutions tailored specifically for small and mid-sized mills, democratizing access to advanced control technologies.

PM: Could you describe the typical technological and operational issues in Indian mills and explain your company’s approach to resolving them?

RP: Indian paper mills, particularly small and mid-sized ones, often grapple with a range of technological and operational challenges. The common challenges faced by the mills include low fiber recovery efficiency, high energy and water consumption, frequent machine breakdowns, and untrained manpower and limited automation.

Inefficient pulping and stock preparation leads to fiber loss. Outdated machinery or sub-optimal processes causes excessive resource use. Lack of maintenance of older equipment, or incompatible system integration results in machine breakdowns. And finally, unskilled manpower and limited automation hinders optimal operation, quality control, and troubleshooting.

Our approach at JMC Paper Tech is holistic and tailored to provide effective resolutions to the mills that includes customized equipment design, comprehensive training and technical support, and retrofit and modernization packages.

We have moved beyond a ‘one-size-fits-all’ mentality. Our machinery is meticulously designed based on a detailed analysis of the mill’s specific raw material mix, the desired end product specifications, and the existing mill layout. This ensures seamless integration and optimal performance.

We also believe in empowering our clients. We provide extensive hands-on training during the commissioning phase of our equipment and follow up with regular technical support. This ensures that mill teams gain the necessary expertise to independently operate the systems efficiently and troubleshoot minor issues.

For mills where a complete new machine investment isn’t feasible, we offer modular upgrade solutions. These packages are designed to enhance specific aspects of performance—such as dewatering, drying, or stock preparation—with minimal disruption and downtime to existing operations.

JMC’s Fiber Pro Stock preparation lines are designed to enhance fiber treatment while simultaneously reducing chemical dependency and minimizing fiber damage.

PM: Given the increasing digitalization, to what extent have Indian mills integrated smart sensors, automation, and AI into their systems? What are the key enablers or barriers in your view?

RP: The adoption of digital technologies in Indian mills is steadily progressing but remains somewhat uneven across the industry. We are at the cusp of a major transformation, and JMC Paper Tech is actively contributing to this shift.

We have announced an upcoming launch of JMC’s proprietary AI tools designed specifically for customer benefits. Our clients will soon have access to a cloud-based JMC’s AI tool, providing readily-available, and comprehensive information about their machinery. This AI technology will empower customers to quickly access machine data and insights whenever needed.

Furthermore, we offer our JMC Mobile App that is freely-available on both Google Play Store and Apple iTunes (search “JMC Mobile APP”). This app provides invaluable calculations related to paper manufacturing, paper machine design, and process optimization, making crucial data easily accessible to mill personnel. While the mobile app is free, the JMC Cloud-Based AI tools will be available at a nominal fee, offering immense utility to our customers.

In the current digitalization landscape, larger integrated mills have notably begun integrating advanced systems such as DCS (Distributed Control Systems) for centralized control and monitoring of complex mill processes; smart sensors for real-time monitoring of critical parameters like consistency, temperature, and moisture, enabling precise process control; and machine vision systems for automated quality inspection, detecting defects and ensuring consistent product quality.

The key enablers include availability of cost-effective PLCs (Programmable Logic Controllers) and SCADA (Supervisory Control and Data Acquisition) systems that have made automation more accessible. Further, with rising awareness about predictive maintenance, mills are increasingly recognizing the value of proactive maintenance to minimize downtime. Lastly, there is a growing demand for traceability and quality assurance. The digital systems provide the data needed for robust quality management.

The barriers include high initial investment which is a significant hurdle for many small and mid-sized mills. There is also lack of trained personnel or shortage of skilled individuals capable of managing and troubleshooting advanced digital systems. The companies are also resistant to change as traditional operational mindsets can sometimes impede the adoption of new technologies.

At JMC, we are actively forging partnerships with leading automation providers to offer integrated smart solutions. Our focus is on making these solutions modular, scalable, and easy to implement, ensuring that mills in India and overseas can embrace digitalization effectively.

The company has introduced agro-based and wood-based pulping equipment that efficiently process diverse raw material sources, offering robust solutions for sustainable fiber sourcing.

PM: Mill owners often demand a balance between performance and cost. How do you ensure your technologies remain both efficient and economically viable, especially for small and mid-sized mills?

RP: We fully recognize that mill owners, especially those operating small and mid-sized mills, require a delicate balance between high performance and economic viability.

Our strategy at JMC Paper Tech is designed to ensure that our technologies are both efficient and economically sound.

We provide high ROI (Return on Investment) solutions. Our machines are not just about upfront cost; they are built to deliver faster payback through significant energy savings, increased productivity, and reduced operational expenses over their lifecycle.

We also have a local manufacturing advantage which is a key differentiator. All our critical equipment is manufactured in-house at our state-of-the-art facility in Sanand, Gujarat. This localized production significantly reduces import duties, logistics costs, and lead times, allowing us to maintain highly competitive pricing without compromising on quality.

We provide flexible, phased automation or machinery upgrade options. This allows mills to invest incrementally in enhancing specific sections of their plant rather than requiring a massive, single-system overhaul, making advanced technology accessible even with limited capital.

We also provide robust after-sales support and spares availability. Our commitment extends beyond installation, offering swift and responsive after-sales service and readily available spares. This minimizes costly downtime and keeps overall operational costs in check for our customers. This comprehensive approach ensures that even smaller mills can achieve world-class output and efficiency, without overspending, contributing directly to their long-term profitability.

JMC Paper Tech has developed compact, high-speed paper machines, with Elite Pro Series, that are specifically engineered for medium-scale mills.

PM: Many Indian mills face inconsistency in raw materials and quality variability. Can your technology or machinery help bring more stability or predictability to mill operations?

RP: Inconsistency in raw materials and quality variability are persistent challenges, particularly in recycled fiber-based operations common in Indian mills. JMC Paper Tech has developed specific, and intelligent solutions to bring greater stability and predictability to mill operations.

The company has advanced JMC’s Fiber Pro pulper and cleaning systems. These systems are engineered to efficiently handle mixed grades of Old Corrugated Containers (OCC) and other recycled fibers. Their robust design effectively separates contaminants, preventing their carryover into the papermaking process, which is crucial for maintaining paper quality.

We have Consistency Control Systems (CCS) in collaboration with our associates. We integrate sophisticated consistency control systems that continuously monitor and adjust pulp consistency. This ensures a uniform pulp quality entering the paper machine, irrespective of variations in the incoming raw material batch.

We have auto dilution and thickening mechanisms. These intelligent mechanisms are seamlessly integrated within our stock preparation lines. They dynamically adjust the pulp slurry’s dilution or thickening based on real-time raw material behavior, ensuring optimal fiber concentration for subsequent processes.

By implementing these technologies, mills can operate more smoothly and consistently maintain critical paper properties such as GSM (Grams per Square Meter), strength, and formation, even when faced with fluctuations in their feedstock.

PM: Are you investing in ‘Make-in-India’ or localization efforts in terms of manufacturing, support, or technology customization?

RP: JMC Paper Tech is a proud and active participant in the ‘Make-in-India’ initiative. Beyond just participation, we are strong proponents of the ’USE MORE PAPER’ initiative, recognizing the sustainable and essential role of paper products.

Our commitment to localization is demonstrated through several key efforts such as expanded domestic manufacturing capacity, indigenization of key components, collaboration with Indian automation partners, region-specific customization, and localized after-sales service network.

We have significantly expanded our state-of-the-art manufacturing facility in Sanand, Gujarat, bolstering our ability to produce high-quality machinery domestically. We have also successfully indigenized the production of several critical paper machine components, including high-performance headboxes, precision calendars, and our energy-efficient steel dryers, which were previously imported. This reduces reliance on foreign suppliers and strengthens the local supply chain.

All our control systems are now being co-developed and integrated with leading Indian automation partners, fostering local technological expertise and ensuring seamless support.

We also offer specialized customizations to meet regional requirements, such as providing specific press felts and forming fabrics optimally suited for operations in water-scarce regions of India.

We maintain a robust and widespread after-sales service network across India, ensuring quick, efficient, and cost-effective support for our customers, minimizing downtime and maximizing operational continuity.

JMC Mobile App provides invaluable calculations related to paper manufacturing, paper machine design, and process optimization, making crucial data easily accessible to mill personnel.

PM: Sustainability is a growing priority. How do your sustainable solutions help mills reduce resource consumption, emissions, or chemical usage? Can you share a recent case study or implementation?

RP: Sustainability is not merely an add-on; it is fundamentally integrated into JMC Paper Tech’s design philosophy, particularly with our JMC’s Elite Pro series.

Our technologies are engineered to significantly reduce environmental impact. We have achieved water usage reduction through advanced save-all systems that recover fibers and water from process effluent, and the implementation of closed-loop water circuits that minimize freshwater intake and wastewater discharge.

For energy consumption optimization, we optimize drying sections through innovative heat recovery systems, capturing waste heat for reuse. Additionally, we integrate energy-efficient pumps and motors throughout our machinery, significantly lowering power consumption.

We have our JMC’s Fiber Pro series for chemical usage minimization. With its improved pulping systems and emphasis on enzyme-integrated stock preparation, it allows mills to reduce their reliance on harsh chemicals, leading to a cleaner process and reduced effluent load.

Also Read: Roto Pumps’ Progressive Cavity Pumps Helping Mills Attain Power Efficiency

PM: Looking ahead, what kind of innovations or technological shifts do you foresee reshaping the Indian paper industry in the next 3–5 years?

RP: Looking ahead, we foresee several transformative innovations and technological shifts reshaping the Indian paper industry over the next 3-5 years.

There will be widespread adoption of circular economy models. This will include comprehensive wastewater recycling systems, advanced chemical recovery processes, and a greater emphasis on closed-loop systems to minimize environmental footprint and maximize resource utilization.

Further, the integration of artificial intelligence will become pervasive, enabling mills to achieve unprecedented levels of quality consistency, drastically reduce waste, and implement highly accurate predictive maintenance strategies to minimize unplanned downtime. The mills will decentralize their automation systems.

We anticipate the rise of more modular, scalable, and cost-effective automation solutions tailored specifically for small and mid-sized mills, democratizing access to advanced control technologies.

There will be development of low-GSM high-strength paper machines, with a significant push towards manufacturing thinner, yet stronger, paper grades. This caters to the growing demand in packaging and export markets, offering material savings and improved logistics.

To further enhance environmental performance, mills will increasingly adopt sustainable bio-based additives and enzyme-integrated processes, reducing reliance on synthetic chemicals and improving overall environmental footprints.

At JMC Paper Tech, we are already actively investing in R&D projects that are precisely aligned with these emerging trends. Our Balaji JMC Paper Mill in Mexico serves as a live laboratory, allowing us to test and perfect these next-generation technologies. This proactive approach ensures that we remain at the forefront of the industry’s transformation, ready to provide our clients with the most innovative and sustainable solutions.

Case Study: Balaji JMC Paper Mill, Mexico (2024-2025)

We are proud to highlight a recent project, a 200 TPD test liner kraft paper mill in Mexico. This facility serves as our dedicated R&D hub, where we rigorously test and refine our innovations in a real-world production environment.

In this project, we have implemented our JMC’s Fiber Pro enzyme-based pulping system, seamlessly coupled with our high-speed Elite Pro series paper machine and an advanced steam hood, yielded remarkable results such as reduction in overall freshwater consumption, steam usage, and chemical costs. Simultaneously, the paper strength was improved, demonstrating that sustainability and enhancements can go hand-in-hand with superior product quality.

This case study exemplifies our commitment to developing and proving sustainable, high-performance solutions before offering them to our clients.