The installation of IntelliJet V Headbox, IntelliPress Linear with IntelliNip Shoe Press and Valmet IQ Scanner in SIPM’s PM6 facilitated excellence in paper production and brought down the final dryness after the press section in the machine to 53.88 percent.

Feb 17, 2025

South India Paper Mills (SIPM), leading manufacturer of paper, paperboard, cartons and corrugated boxes in Karnataka, has applauded the advanced technologies provided by Valmet for its containerboard machine (PM6), which not only improved paper quality, but reduced energy consumption and production costs.

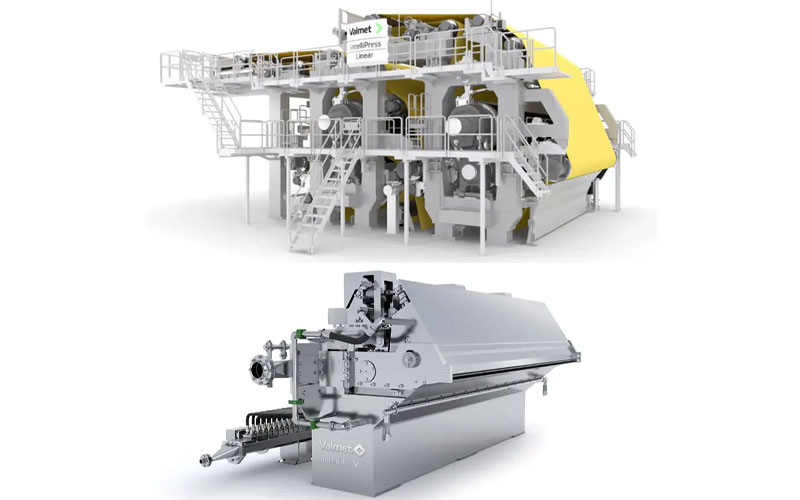

The installation of IntelliJet V Headbox, IntelliPress Linear with IntelliNip Shoe Press and Valmet IQ Scanner in SIPM’s PM6 in 2020 facilitated excellence in paper production and brought down the final dryness after the press section in the machine to 53.88 percent.

Watch: In Pursuit of Lesser Water Footprint

According to Mr. Manish Patel, owner and Managing Director of SIPM, the company decided to make a large investment in PM6 in order to fulfil its commitment to innovation, quality improvement and sustainability in the container board conversion industry. The design speed of the machine is 800 m/min, the reel width is 3,950 mm, and the basis weight range is 80-300 g/m2.

The decision further aimed at enabling the converters to produce corrugated boxes with a high-quality paper matching the global standards. SPIM decided to cooperate with Valmet because of the advanced technologies offered by the global technology solutions provider.

The IntelliJet V Headbox has been running very well on converting machines with low rejections and low losses to the converters. This has led to improved the productivity of the converter and energy efficiency, leading to cost savings. The Valmet IQ scanner has efficiently controlled dilution in the headbox. These changes helped SPIM to produce paper with excellent profiles, providing opportunities for nicer graphics and printing.

Also Read: Cardinal Tissue Acquires 2 Facilities of Softex Paper in US

“There’s a huge learning curve for our people, because many of these technologies are the latest, like the shoe presses and the headbox. Controlling these and effectively & consistently producing a product with good uptime is what we are targeting right now,“ he added.