Established in 1972, ST Macchine, an Italian company is a leader in designing, manufacturing, assembling and commissioning equipment for stock preparation, hydraulic, rectifier roll and crescent former headboxes, fourdriniers and water treatment systems. Recently they have added a breast roll shaker contributing to a more homogeneous distribution of fibers and an increased orientation of the ones in cross direction.

ST Macchine has developed a unique solution where each rotating mass is moved by an independent servo motor and the synchronism between rotors is electronic. The shaker slides over standard ball rail systems. This allows ST Macchine system to eliminate gears, special joints, oil unit for lubrication and hydrostatic support of sliding trolley and breast roll bearings. We can achieve the same performances of other manufacturers with a simpler device. Energy consumption is limited and maintenance is reduced.

In the past the breast roll shaker was realised by a crank and slider mechanism. This operating principle was limited to shaking stroke and frequency, transmitting very high forces to the foundations. This system lead to heavy and costly civil works.

The shaker effects are strictly related to the ratio between its frequency and machine speed. A certain relationship must be maintained between the shaking frequency and the paper machine speed. As the speed of the machine increases during the years, shaking frequencies are required to increase as well up to values which are not achievable by traditional shakers. Hence the need to create a new shaker technology based on higher dynamics was realised.

Watch: In Pursuit of Lesser Water Footprint

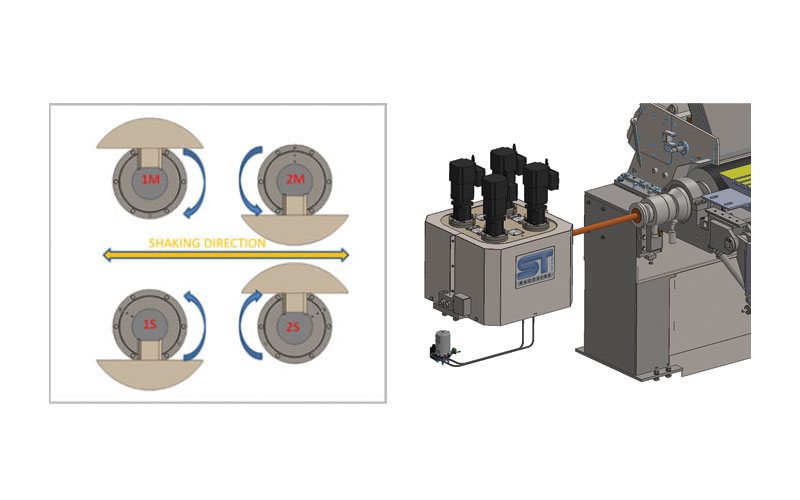

As other manufacturers, ST Macchine breast roll shaker uses the principle of four eccentric masses divided in two pairs that rotate on their axes and are synchronized. Those masses are mounted on a trolley that is connected through a rod to the breast roll. This spinning creates a force that is transmitted only to the breast roll and not to the foundations. Due to this technology it is possible to reach very high performances of stroke up to 25 mm, and frequency from 150 to 600 Hz.

Compared with conventional shaking units, the four eccentric masses system, which oscillates freely in horizontal direction, transfers negligibly small friction, centering forces to the base- thanks to the momentum conservation law. The foundation has only to support the dead weight of the unit. In this way no disruptive reaction forces are transferred to the headbox or wire section.

There are several benefits of the new ST Macchine shaker. At first, having a motor per each mass, no gear is needed. Secondly, the motors directly set the masses in motion i.e. the direct coupling of the motor with the mass eliminates joints. Last, the vertical position of the masses makes our new system independent from any gravitational problem.

Also Read: FPTA Concludes 63rd AGM on High Note, Resolves to Replace Single-Use Plastic with Paper

The whole system is installed on a static base, while the movement is guaranteed by sliding guides. The movement is guaranteed by the standard ball rail system, avoiding any need for a hydraulic unit. Such systems can accept some loads due to imperfect alignment between breast roll and shaker axes. A traditional hydraulic rail system does not accept such an offset. Both eccentric mass bearings and linear guides are grease lubricated and connected to an electric unit for automatic greasing.

Our design allows us to eliminate any hydraulic control unit. Less moving parts and absence of hydraulic unit lead to higher reliability and less maintenance. Even with four motors, the total installed power is lower than 25 KW. The supply is complete with the electric cabinet containing drives and a supervision system for the synchronization of the four axes.

The operator interface is by means of a touch panel that allows the local regulation and supervision of the shaker. The touch panel can be connected to the DCS for remote operation. The breast roll support can be set through the traditional, simple and reliable scotch-ply or the innovative sliding bearings.