With Toscotec tissue machines of different models and configurations, Vinda Group’s production capacity has reached over 1 million tonne per year.

September 6, 2016

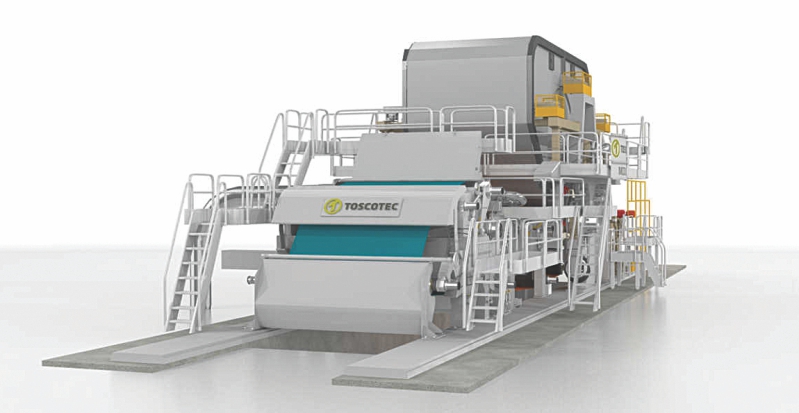

Toscotec’s strategic development of customized designs and state-of-the-art solutions for energy reduction has won them another order from Vinda Paper known for its sustained progress and outstanding growth. After the recent addition of TM9 and TM10 by Toscotec, Vinda Paper (China) Co. Ltd. has achieved startup of ten Toscotec tissue machines of different models and configurations in less than four years.

Furthermore, Vinda Paper (Shandong) Co. Ltd. fired up one AHEAD-1.5M ES tissue machine, which is already running at the speed of 1,500 mpm. The fourth machine installed in the Shandong mill, has a design speed of 1,700 mpm and a net web width of 3,400 mm. The AHEAD-1.5M tissue machine installs Toscotec’s second generation Steel Yankee Dryer TT SYD, steam-heated hoods and large suction press roll (with a diameter of 1425 mm).

Based on the remarkable results of previous projects, Vinda Group has once again chosen to invest in Toscotec’s tissue machine technology, which benefits from a comprehensive energy-saving concept, the TT DOES (Drying Optimization for Energy Saving) package. Apart from TM4, Vinda’s Shandong mill hosts other three Toscotec-supplied machines: TM1 & 2 are AHEAD-1.5S ES, steadily running at 1500 m/min and TM3, identical to TM4, started-up last November, is now running at 1,600 mpm.