Trident Group is actively exploring pilot-scale digital twin modules across its energy-intensive operations. In an exclusive interaction with Paper Mart, Mr. Rajnish Kumar Gera, CEO – Paper, Trident Group, shares how this cutting-edge technology can significantly enhance productivity, enable predictive maintenance, and ensure smoother paper conversion cycles with minimal waste . It also aids in resource conservation by reducing process variability and enhancing material yields. He believes that the future of digital twin technology in India’s paper industry is both promising and transformative, driven by smart manufacturing, ESG imperatives, and competitive differentiation.

Paper Mart: What role does digital twin technology play in paper industry operations today?

Rajnish Kumar Gera: Digital twin technology—virtual replicas of physical assets, systems, or processes—is revolutionizing the paper industry by enabling real-time monitoring, predictive maintenance, and performance simulation.

In today’s global paper manufacturing context, digital twins are used to mirror mill operations from pulp preparation to paper finishing lines, optimizing machinery efficiency and quality control.

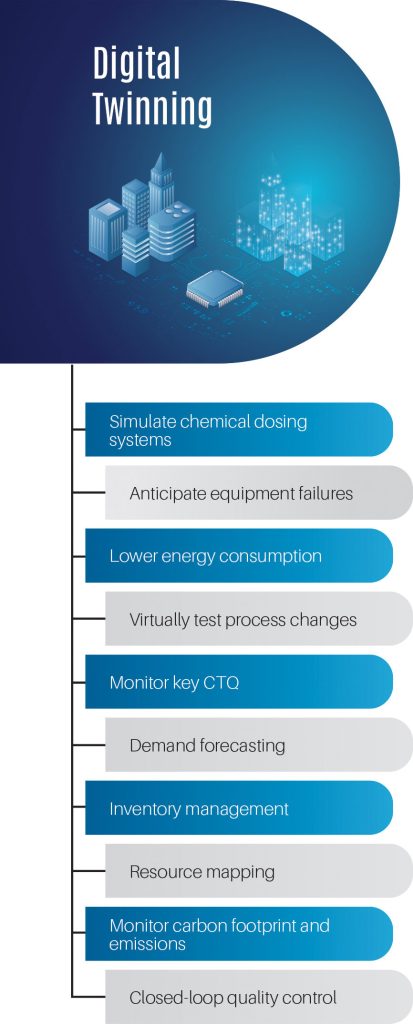

For instance, mills use digital twins to simulate chemical dosing systems, anticipate equipment failures, and reduce unplanned downtime. These digital twins continuously collect data from equipment like rollers, dryers, and cutters, generating predictive alerts to proactively schedule maintenance and extend equipment life.

They also allow papermakers to virtually test process changes, monitor key CTQ (critical-to-quality) parameters such as moisture content, thickness, and tensile strength, and explore energy conservation avenues before any physical intervention, ultimately reducing waste and improving output.

Demand forecasting and inventory management have also seen an uplift with historical data and market trends being harnessed through digital twins to avoid overstocking or shortages.

At Trident Group, while digitalization is a core enabler across verticals, we are actively exploring pilot-scale digital twin modules across our energy-intensive operations to benchmark productivity and enable pre-emptive maintenance, ensuring smoother paper conversion cycles and minimal waste generation.

Watch: In Pursuit of Lesser Water Footprint

PM: How do you view the potential or readiness for digital twin applications in Indian paper mills?

RKG: The Indian paper industry stands at a pivotal juncture where technology adoption is no longer optional. While digital twins are still nascent in Indian mills, there is increasing interest, especially among integrated and sustainability-driven manufacturers.

Government programs like ‘Digital India’ and ‘Make-in-India’ initiative have laid the groundwork for digital transformation across manufacturing sectors, including pulp and paper. Mills are beginning to embrace Industry 4.0 technologies such as IoT, AI, and cloud computing, crucial foundations for effective digital twin deployment.

With rising demand for operational transparency, traceability, and compliance, readiness is growing, especially in areas like: Predictive maintenance of critical paper-making assets, energy and steam consumption optimization, quality variation monitoring using IoT-linked twins, smart mill operations and real-time decision-making, and sustainability management aligned with ESG goals.

Trident Group, as the world’s largest wheat-straw-based paper manufacturer, has laid robust groundwork with investments in automation and sensor-based systems, creating the foundational digital backbone needed for full-scale digital twin integration.

Mills are beginning to embrace Industry 4.0 technologies such as IoT, AI, and cloud computing which are crucial foundations for effective digital twin deployment.

PM: What are the key benefits of implementing digital twins in terms of sustainability, cost reduction, and process optimization?

RKG: Digital twin integration offers multifold benefits for the paper industry:

Sustainability: By enabling simulations before physical trials, digital twins help reduce raw material consumption, water use, and energy loads. They allow mills to model environmental impacts over time, minimize emissions, and ensure better compliance with regulatory norms. Digital twins can further drive resource conservation by reducing process variability and enhancing material yield. Notably, we are planning to reduce our GHG emission of Scope 1 & 2 by 2031 as per the SBTi compared to base year 2021. Further, we have planted 10,000 organic trees with 50+ varieties of organic species of plants spread over 3 acres of land. We are using renewable energy from various sources such as agro product rice husk and biomass, ETP sludge and black liquor to attain resource conservation (instead of coal as a replacement we are using a majority of the mentioned renewable energy sources).

Cost Reduction: Predictive insights reduce machine downtime, optimize maintenance schedules, and decrease breakdown frequency, resulting in reduced repair costs, fewer rejects, and lower energy consumption. Better demand forecasting and raw material planning also cut overproduction and inventory costs.

Process Optimization: Digital twins allow real-time adjustments to maintain product quality and enhance responsiveness to process variations. By integrating data from sensors, ERP systems, and analytics platforms, they support dynamic experimentation and innovation with minimal risk. Key process parameters like pulp consistency, dryer loads, and coating thickness can be fine-tuned for peak efficiency.

In today’s global paper manufacturing context, digital twins are used to mirror mill operations, from pulp preparation to paper finishing lines, helping optimize machinery efficiency and quality control.

PM: What are the challenges in adopting digital twin tech in paper mills?

RKG: Several challenges like high capex, digital skill gap, cultural resistance, cybersecurity and lack of standards, hinder digital twin adoption, particularly in legacy or fragmented mill setups. Retrofitting legacy machinery with IoT sensors and data platforms can be capital-intensive and technically complex. The availability of skilled personnel to manage AI/ML models and digital workflows is limited. Operational teams may resist new technology due to fear of job displacement or unfamiliarity. Enhanced connectivity increases exposure to cyber risks, making secure data transmission and IoT protection critical. Absence of universal standards can lead to custom, non-scalable solutions and vendor lock-in.

However, at Trident Group, we are systematically overcoming these barriers by investing in digital literacy programs, forging industry partnerships, and deploying advanced monitoring systems across our process units. Our long-term tech roadmap is aligned to support scalable digital twin modules.

Also Read: Bellmer: Digital Transformation is No Longer Optional — It’s a Strategic Imperative

PM: What do you see as the future of digital twin technology in the paper industry, especially in India?

RKG: The future of digital twin technology in India’s paper sector is promising and transformative, driven by smart manufacturing, ESG imperatives, and competitive differentiation. With an estimated CAGR of 45.9% for digital twin adoption in the Asia-Pacific region, India is poised to be a key contributor.

Sustainability will be a core driver, where digital twins will help monitor carbon footprint and emission data, enable closed-loop quality control, enhance energy efficiency and resource mapping, improve traceability, particularly in agri-residue-based production, and support agile and adaptive manufacturing systems.

For Trident Group, whose paper division champions circularity and biomass-based energy, digital twins represent the next leap in operational excellence. As India’s digital infrastructure and industrial IoT ecosystem matures, greater adoption is expected within 3–5 years, especially among vertically integrated and future-ready manufacturers like Trident.

With an estimated CAGR of 45.9% for digital twin adoption in the Asia-Pacific region, India is poised to be a key contributor.