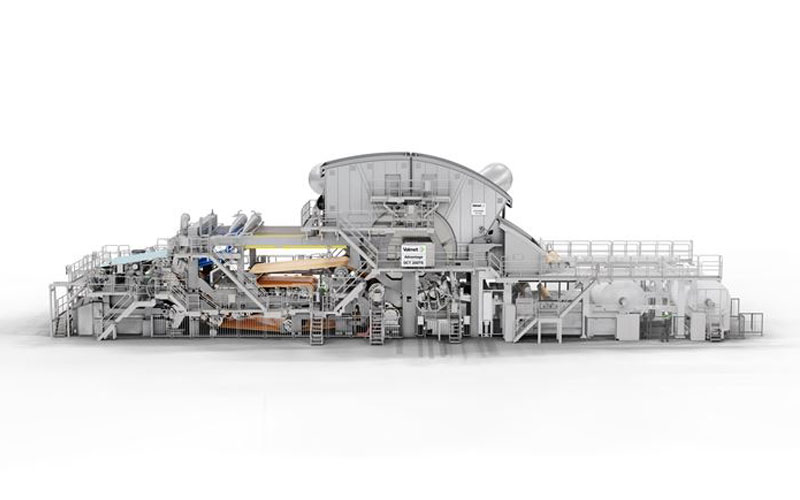

The third Valmet Advantage DCT tissue line to be delivered at Velvet CARE’s mill in Osada Klucze, Poland, will have a design speed of 2,200 m/min, a width of 5.6 meters, and an annual production capacity of 70,000 tons. The tissue line is optimized to save energy and deliver excellent paper properties.

Jul 15, 2024

Velvet CARE has decided to invest in a third Valmet Advantage DCT tissue line for its mill in Osada Klucze, Poland. The order includes an extensive automation package, a control valve package, and Industrial Internet solutions. The target is to meet consumers’ increasing demand for high-quality tissue products with low environmental impact.

The order is included in Valmet’s orders received in the second quarter 2024. The value of the order will not be disclosed.

Valmet and Velvet CARE have a strong history of cooperation, and Valmet has previously delivered two tissue lines to the same mill, starting up in 2018 and 2021.

Valmet’s Advantage DCT 200 tissue machine is equipped with the latest technology to ensure the highest product quality while reducing energy and water consumption and CO2 emissions. Valmet’s scope of supply comprises an Advantage DCT 200 tissue machine equipped with an OptiFlo headbox and a Yankee cylinder. The line will also feature Advantage tissue technology, including a ViscoNip press, an AirCap Advantage hood with an air system, WetDust systems, and a SoftReel reel.

Watch: Top Paper Companies 2023

Valmet will also deliver detailed mill engineering, full stock preparation equipment, a manual pulper feed system, and an automation package, including a Valmet DNA Distributed Control System (DCS) with built-in machine condition monitoring and a Valmet IQ Quality Control System (QCS). The delivery will include a control valve package with valve automation solutions. Valmet Tissue Performance Center services are also part of the scope.

The new tissue line will have a design speed of 2,200 m/min, a width of 5.6 meters, and an annual production capacity of 70,000 tons. It is optimized to save energy and deliver excellent paper properties.

“We appreciate Valmet for being an indispensable partner in Velvet CARE’s success. The cutting-edge technology and unwavering support have elevated our operations, making Valmet an invaluable contributor to our industry leadership. We look forward to continued collaboration and shared success,” says Ms. Wanda Ciesielczuk, Vice President, Velvet CARE.

Also Read: Voith Takes Next Step in Building Autonomous Paper Mill

“It has been a pleasure to follow Velvet CARE from the start-up of their first Valmet machine. They pay attention to all details required to produce premium tissue with high efficiency, focusing on quality in all aspects. We are proud to be chosen again as their supplier and look forward to working together to make the new machine as successful as the previous two,” says Mr. Joakim Karas, Capital Sales Manager, Tissue Mills business unit, Paper business line, Valmet.