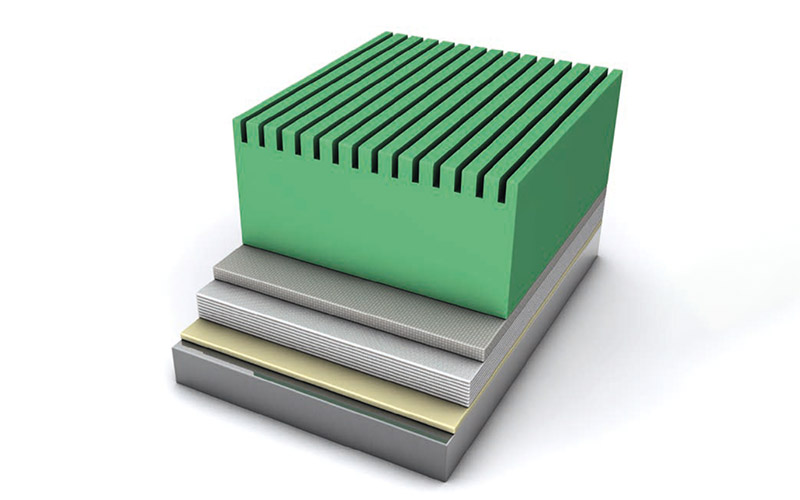

Voith is the first supplier on the market to develop a press roll cover made from bio-based materials. With SolarPress Green, Voith offers bio-based polyurethane press roll cover with a hardness range of 5 to 20 PJ. The new press roll ensures optimal dewatering performance and high functional reliability, even under extreme operating conditions.

Feb 27, 2025

Voith has expanded its sustainable portfolio with another sustainable solution, SolarPress Green, along with SolarFlow Green and AiroGuide Tune Green sustainable solutions that sets new standards in the paper industry.

With SolarPress Green, Voith offers another bio-based polyurethane press roll cover with a hardness range of 5 to 20 PJ – while providing the same mechanical performance as the proven SolarPress roll cover.

Watch: In Pursuit of Lesser Water Footprint

Voith is the first supplier on the market to develop a press roll cover made from bio-based materials. The use of renewable materials significantly reduces the proportion of fossil-based raw materials in the product. At the same time, it ensures that the renewable raw material does not compete with food supplies.

The press roll cover is certified according to the internationally recognized DIN CERTCO for bio-based products. The cover combines all the advantages of the proven SolarPress technology while reducing the carbon footprint. This innovation is perfectly aligned with Voith’s longstanding commitment and goals of driving sustainability in papermaking and in its own production.

Dr. Christina Bauer, Global Product Manager of Press Roll Covers at Voith, said, ‘‘With SolarPress Green, we are reducing the use of fossil raw materials and actively contributing to resource-saving paper production – without compromising performance and efficiency. Together with our customers, we are setting new standards for a sustainable future in the paper industry.’’

Also Read: India Among 24 Nations Approved for EU Recycled Material Imports

The bio-based polyurethane press roll is made with specially developed material that ensures optimal dewatering performance and high functional reliability, even under extreme operating conditions. Thanks to its high chemical and abrasion resistance, the cover remains durable and reliable. The high stability of the bio-based polyurethane enables use under extreme nip conditions, which in turn enables high machine speeds, increased dry content and reduced energy consumption.

With an emphasis on the ‘Papermaking for Life’ program, Voith Paper is introducing a wide range of technologies and initiatives that will lead to more efficient and sustainable processes in paper production. The key focus is on the areas of water, energy and fiber savings; digitalization; innovations; and partnerships as levers for more sustainable production.