Performance of the each of the ESG principles are being reviewed periodically by various committees led by Management. West Coast Paper has adopted ‘minimum impact-best process’ technology that involves green production, resource conservation, responsible waste management and a reduced pollution load, as its core dimensions. During the year the company managed to save 1,02,683 GJ of energy as a result of various energy saving initiatives. The company is continuously focussing on reducing its carbon footprint. The company follows 3R principle (Recycle, Reuse and Reduce) and more focus is being given at controlling at source instead of end of pipe treatment. There is significant awareness in zero accident & environment management culture and it is being brought in DNA of employee. This is helping the company to produce quality product in cost efficient manner.

In an interaction with Paper Mart magazine, West Coast Paper Mills (WCPM) share a report highlighting ESG related challenges, targets and achievements.

Watch: Top Paper Companies 2023

Environment

- Afforestation

During FY 23-24 around 1 crore quality seedlings and saplings were planted in nearby area of Subabul, Casuarina and Eucalyptus plantations. Company has set target for 1.25 crores distribution in FY 24-25. More focus is on to improve wood resource availability and increase in farmer income. - Reduction in Water Consumption

Water consumption reduction is priority area. Water consumption per ton of product has reduced from 91 KL in 2015-16 to 58 KL in 2022-23 i.e., by around 37%. Various water conservation schemes are under implementation. Section wise water audit has been done and it is being reviewed on daily basis. - Reduction in Carbon Foot Print

Steam consumption per ton of product has reduced from 9.52 MT in 2015-16 to 8.79 MT in 2022-23 i.e., by around 8%. Similarly, various power consumption reduction schemes are under implementation. In future new capex is being planned for steam & power reduction. - Responsible Waste Management

The company has put in place a waste management system wherein the focus is on recycling/ recovering of waste input material to the extent possible. Nearly 97% of the chemicals used in pulping process are recovered back in the chemical recovery complex and recycled. Further, almost 20% water used in the process is recycled and reused. Fly ash is being used for making eco-bricks. ETP sludge is being used for cardboards/egg tray manufacturing. - New-Gen Fiberline with ECF Bleaching Sequence

The company’s investment in a 725 TPD Metso fiber-line, replacing the old unit with environmentally benign elemental chlorine free (ECF) bleaching process in the in-house pulping street has enabled us to produce consistent quality of high-bright and hi-strength pulp with improved cleanliness and lasting freshness with least pollution load. The high degree of bleaching has improved the optical properties of paper. - WCPM AND FSC® Certification

The Company is certified for FSC® Chain of Custody which indicates that the company is using wood from responsible forests and well-managed plantations and ensures that only legally harvested wood is used for manufacture of paper/paperboard. The products come from forests that are managed responsibly to address the social, economic and ecological needs of the present and future generations. The company has already received two certifications in this regard. The Society for Afforestation, Research and Allied (SARA) promoted and supported by WCPM has obtained the certificate for being a ‘Well Managed Group Plantation’ since 2011. At present, the Company is in a position to manufacture FSC® certified products viz; FSC® -100%, FSC® -MIX in its printing & writing papers and FSC® -Recycled logo on paperboards. - ISO 14001 Certifications

WCPM’s high operational standards have been endorsed by the globally renowned certifications from agencies of great repute. The company enjoys the ISO 14001 certification for designing and implementing a comprehensive Environment Management System (EMS) in line with the global standards.

Also Read: Leading by Example: Kuantum Papers’ Commitment to ESG in the Paper Industry

Social

More focus is being given on training, behaviour, health and safety aspect and to improve work environment by involving top to bottom personnel. Effective implementation of these programs has positively reflected in reduction in injuries among workers from 8 in FY 21-22 to 1 in FY 22-23.

Our endeavour to provide quality products to our customers is demonstrated through 30% reduction in consumer complaints with regards to quality of our products.

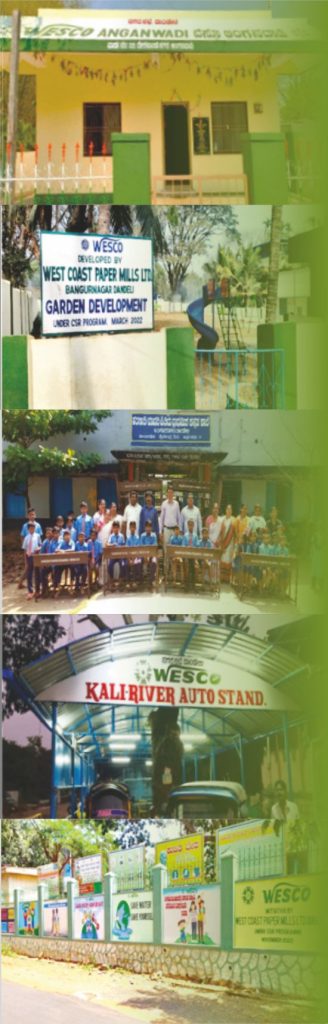

Our organization continued to engage with communities and provide necessary support to marginalised and vulnerable communities through our CSR programs.

Governance, Leadership and Oversight

The company is a responsible corporate citizen. The company is committed to green production, resource conservation and responsible waste management. The company has adopted ‘minimum impact-best process’ technology that involves green production, resource conservation, responsible waste management and a reduced pollution load, as its core dimensions. During the year the company managed to save 1,02,683 GJ of energy as a result of various energy saving initiatives. The company is continuously focussing in reducing its carbon footprint. The company follows 3R principle (Recycle, Reuse and Reduce) and more focus is being given at controlling at source instead of end of pipe treatment. There is significant awareness in zero accident & environment management culture and it is being brought in DNA of employee. This is helping the company to produce quality product in cost efficient manner.