Kuantum Papers has embraced water circularity by recycling over 90% of its paper machine processed water for critical operations and achieving 3,000 m³ per day freshwater savings. The company has made significant investments in advanced technologies such as High-Rate Solid Contact Clarifiers (HRSCC), Multi-Plate Settlers (MPS), and Condensate Polishing Units (CPU)—to optimize water reuse, ensure stable water quality, and minimize production disruptions. In an exclusive interview with Paper Mart, Mr. Nandivardhan Morareddy, Vice President – Technical Excellence at Kuantum Papers Limited, shared the company’s plans to adopt advanced membrane technologies like Reverse Osmosis (RO) and Ultrafiltration (UF) to further enhance recycled water streams. With these initiatives, Kuantum Papers aims to achieve near-zero freshwater intake and reduce its water consumption to below 30 m³ per ton of paper by 2027.

Paper Mart: How has your understanding or approach to water circularity evolved over time? How close are you to achieving it?

Nandivardhan Morareddy: At Kuantum Papers, our journey toward water circularity has evolved from basic reuse practices to the adoption of fully integrated, closed-loop water management systems across our operations.

Initially, our efforts were centered on recycling machine water, but over the years, we have strategically invested in advanced technologies such as High-Rate Solid Contact Clarifiers (HRSCC), Multi Plate Settlers (MPS) and Condensate Polishing Units (CPU). These investments have enabled us to maximize internal water recycling and maintain high-quality process standards. Today, we recycle over 90% of our paper machine processed water internally, and our treated effluent supports irrigation for 2,000 acres of agricultural land.

We are progressively advancing toward full water circularity, aiming to reduce water consumption to less than 30 m³ per ton of paper by 2027. Our approach is rooted in continuous innovation and operational excellence, as we consistently evaluate and optimize processes to meet our sustainability goals while delivering value to our stakeholders.

Watch: In Pursuit of Lesser Water Footprint

PM: To what extent have you implemented internal water reuse, recovery, or circular systems (including ZLD, water loop closure, or rainwater harvesting)?

NM: We have established a highly efficient internal water reuse system across our operations. Over 90% of machine water is recycled for critical uses such as showers, dilution, pulp washing and cleaning. Additionally, sealing water is systematically collected, clarified and reused, achieving approximately 80% recycling efficiency. Our Effluent Treatment Plant (ETP) plays a pivotal role by enabling 100% reuse of treated water for agricultural irrigation via a 15-kilometer pipeline network.

In a major step toward reducing dependency on groundwater, we have got approval from the Punjab Government to draw water from the nearby canal and now this surface water accounts for 70% of our water intake.

While we have not yet implemented full Zero Liquid Discharge (ZLD), we are exploring emerging technologies and improving our recycling techniques to maximise treated effluent reuse and minimize freshwater intake. We are assessing how we can integrate AI-driven analytics which will allow us to further adapt water circularity in our operations.

We have achieved freshwater savings of over 3,000 m³ per day through the implementation of Twin Roll Presses, HRSCCs, MPS units and other innovations.

PM: Which technologies or solutions have you found most effective in reducing your freshwater consumption or increasing internal recycling?

NM: We have adopted several advanced technologies that have proven highly effective in reducing freshwater consumption and enhancing internal recycling.

Our High-Rate Solid Contact Clarifiers (HRSCC) have significantly improved water quality by reducing suspended solids, allowing for reuse across multiple stages of the production process.

The introduction of Twin Roll Presses in the agro and wood pulping sections has led to a reduction of water consumption by 4 m³ per ton of pulp.

Multi Plate Settlers (MPS) have successfully reduced Total Suspended Solids (TSS) to below 30 ppm, enabling water reuse even in sensitive processes. Our Condensate Polishing Units (CPU) have contributed to daily savings of up to 300 m³ of water by improving the reuse of condensate water.

Additionally, the adoption of injectable packings for pumps and optimized shower nozzles has helped reduce water demand and seal water consumption significantly, reinforcing our circular water management practices.

PM: What are the biggest roadblocks (technical, financial, or regulatory) in achieving higher levels of water reuse or moving toward ZLD?

NM: Despite our progress, we face several challenges in advancing water reuse and moving toward ZLD. From a technical standpoint, as the number of recycling cycles increases, the accumulation of Total Suspended Solids (TSS) can impact water quality and lead to equipment clogging.

This requires the implementation of advanced clarifiers and continuous chemical optimization. Water loop closure often leads to scaling and fouling, which affect operational efficiency and equipment longevity.

Financially, high capital expenditure is required for advanced treatment systems such as RO, ultrafiltration or electrocoagulation, particularly for large-scale plants. Further, maintaining product quality necessitates constant adjustments to ‘wet end chemistry’ and water parameters in various process areas when recycled water is in use.

Nonetheless, through sustained investment in infrastructure and innovation, we continue to make tangible progress toward our circular water goals.

Our long-term strategy includes deploying AI-based process control and real-time monitoring to optimize water loops, along with the setup of pilot ZLD modules for strategic sections like the bleach plant.

PM: How do local or national regulations affect your water management goals? Have sustainability mandates accelerated your water-saving initiatives?

NM: Indian regulatory frameworks, including the Central Pollution Control Board (CPCB) and State Pollution Control Boards (SPCBs) have positively influenced our water management goals.

Compliance mandates concerning effluent quality, freshwater abstraction limits and zero-effluent agriculture reuse policies have strengthened our internal targets. Far from being restrictive, these compliances have encouraged us to invest in advanced water clarification and recycling infrastructure and adopt canal-based surface water sources, thus reducing groundwater dependency.

PM: Have your investments in water reuse or ZLD technologies paid off in terms of savings, efficiency, or compliance?

NM: Our investments in water reuse and recycling technologies have delivered multiple returns. We have achieved freshwater savings of over 3,000 m³ per day through the implementation of Twin Roll Presses, HRSCCs, MPS units and other innovations.

There has been a significant reduction in operational costs related to water sourcing, softening, and wastewater treatment. Moreover, by utilizing treated water for agricultural irrigation, we have provided a steady source of water to our farmer community thereby strengthening our relations with them. Above all, the stability in water quality and availability has minimized the risk of production disruptions, thus improving overall operational resilience.

PM: Do you involve technology providers in planning or customizing your water treatment systems? Any successful collaborations worth sharing?

NM: Collaboration with technology providers, consultants, chemical suppliers and OEMs is an integral part of our water management strategy. We have worked closely with these partners to tailor our HRSCC systems for both machine water and high COD streams.

Our partnerships with chemical suppliers have been instrumental in refining wet end chemistry to maintain paper strength and retention characteristics while increasing recycled water use. We have also successfully designed and installed multi-stage clarifiers and condensate polishing systems in collaboration with water treatment experts.

These collaborations have enhanced the flexibility, efficiency and robustness of our systems and continue to play a vital role in our journey.

PM: How do you see your water use evolving in the next 5–10 years? What would “full circularity” look like in your operations? What kinds of support in terms of technology, partnerships, or policies would help you get there?

NM: In the next 5–7 years, Kuantum Papers envisions a significant transformation in our water use profile. We are on track to reduce consumption to below 30 m³ per ton of paper by 2027 and we aim to approach near-zero freshwater intake for core operational processes. We are exploring advanced membrane technologies such as reverse osmosis and ultrafiltration to further improve recycled streams, while implementing rainwater harvesting for integration into our plant’s water system.

Our long-term strategy includes deploying AI-based process control and real-time monitoring to optimize water loops, along with the setup of pilot ZLD modules for strategic sections like the bleach plant.

To support these ambitions, we seek continued technological innovation, especially in cost-effective, energy-efficient polishing systems and stronger partnerships with startups, academic institutions and technology companies. Policy incentives for water recycling infrastructure and the adoption of green technologies would also be pivotal in accelerating this transition.

PM: Have you considered or implemented digital twins to simulate, monitor or optimize your water use? What kind of improvements could such systems bring to your operations?

NM: We are actively evaluating the use of digital twin technologies to enhance our water and energy management systems. These virtual models offer the potential real-time optimization of recycling loops and chemical dosing. They also enhance operational transparency by identifying water loss points quickly and accurately. Through simulation, we can test and refine water-saving strategies before deployment, minimizing risk and maximizing impact. We believe the adoption of smart monitoring systems will be critical to achieving full water circularity and realizing our vision of zero waste discharge.

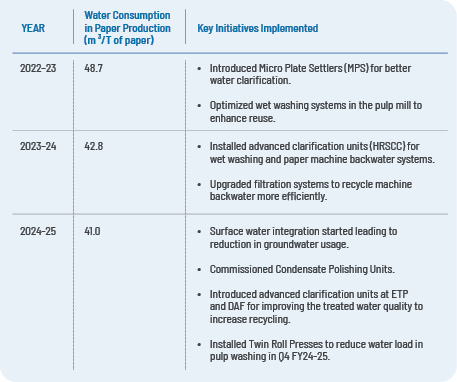

PM: What is your current annual water consumption, and how has the consumption reduced over the past few years? Kindly support the answer with the table below.

NM: At Kuantum Papers, consistent efforts toward improving water efficiency, recycling and reuse have led to measurable reductions in our annual freshwater consumption.

Our strategic focus on upgrading technology, addition of water recycling systems, implementing surface water usage and optimizing internal water loops has significantly decreased freshwater consumption and reliance on groundwater while improving overall operational sustainability.

Below is a summary of our annual water consumption trend over the past three years: