Every piece of production equipment in a mill has a range where it performs extremely well, and also mechanical limitations where performance is less than optimum. Building on technical strengths and overcoming limitations are what motivates ANDRITZ engineers to innovate new designs – such as the VST.

With over 500 units in operation, the ANDRITZ Screw Press (SCP) is regarded as being top of the line. But, even a premiere product has practical limits. In the case of the SCP, the limitation could be observed in applications with lower feed consistencies (e.g., 3-6%). “How can we remove the limitations in lower feed consistency applications – while keeping the inherent design strengths of the SCP?” That was the question that ANDRITZ engineers answered when developing the VST.

THE IDEA BEHIND DEVELOPMENT OF THE VST

Simply described, the VST is a vertical configuration of the SCP, with some important differences. In an SCP, the pulp is fed into the inlet housing of the unit and dewatered via a rotating screw that tapers to increase the dewatering effect on the pulp. Feed consistencies are typically in the range of 5-10%. The dewatered pulp is discharged by gravity from the outlet casing at the end of the rotating screw. Typically, outlet consistencies in the range of 26-30% are achieved.

The horizontal design has two main limitations:

- At low feed consistencies (3-5%) the holes of the screen baskets in the inlet zone tend to plug; and

- There tends to be uneven filling of the press across the complete area of the dewatering screen.

These two limitations reduce the throughput and discharge dryness of the pulp. The VST was designed to overcome these limitations in specific applications.

THE IMPACT OF HYDROSTATIC PRESSURE

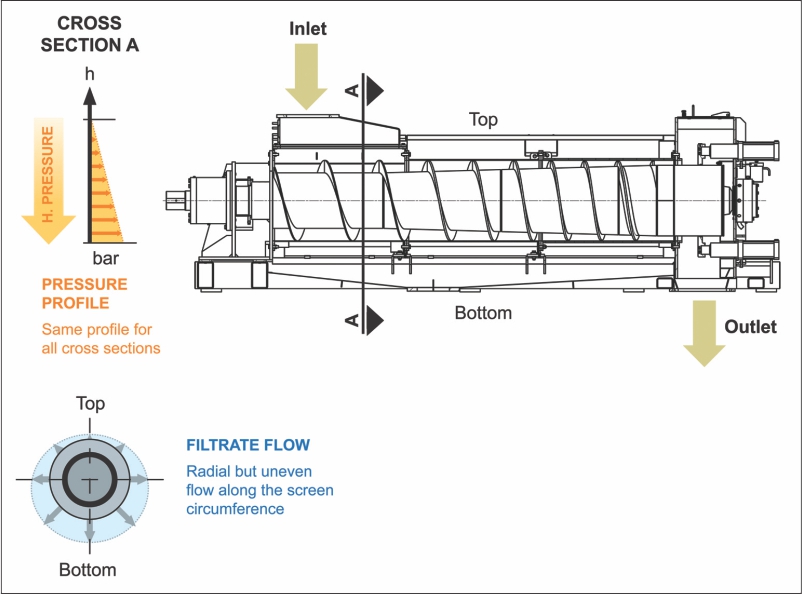

The SCP is fed from the top through the headbox into the first dewatering section. Due to the height difference between the top and bottom of the dewatering screen, hydrostatic pressure builds up in proportion to the diameter of the press (see figure 1). For large screw presses, this hydrostatic pressure can be up to 0.1 to 0.15 bar.

This pressure creates uneven filtrate flows around the screen circumference. There is lower filtrate flow at the top of the press where the hydrostatic pressure is low and a higher flow at the bottom of the screen basket where the hydrostatic pressure is highest. This pressure profile is consistent over the length of the dewatering screw.

Particularly in applications with low feed consistencies, the hydrostatic pressure can already be too high at the beginning of the dewatering process. The speed of the filtrate flow through the screen basket is at such a level that fibers can be dragged into the holes and build up a layer on the surface of the screen – reducing dewatering efficiency.

Another limitation of a horizontal design is the difficulty in obtaining uniform filling, and thus uniform dewatering, through the three dewatering zones (low-, medium- and high-pressure) and over the full length of the screw. An uneven filling degree means that the available screen area is not fully utilized and that no dewatering force is applied to some of the pulp suspension and the dewatering efficiency is reduced. When observing an SCP during operation, areas along the screw shaft with good dewatering (where a lot of filtrate is squeezed out) and areas where less dewatering takes place are visible.

TAKING IT VERTICAL

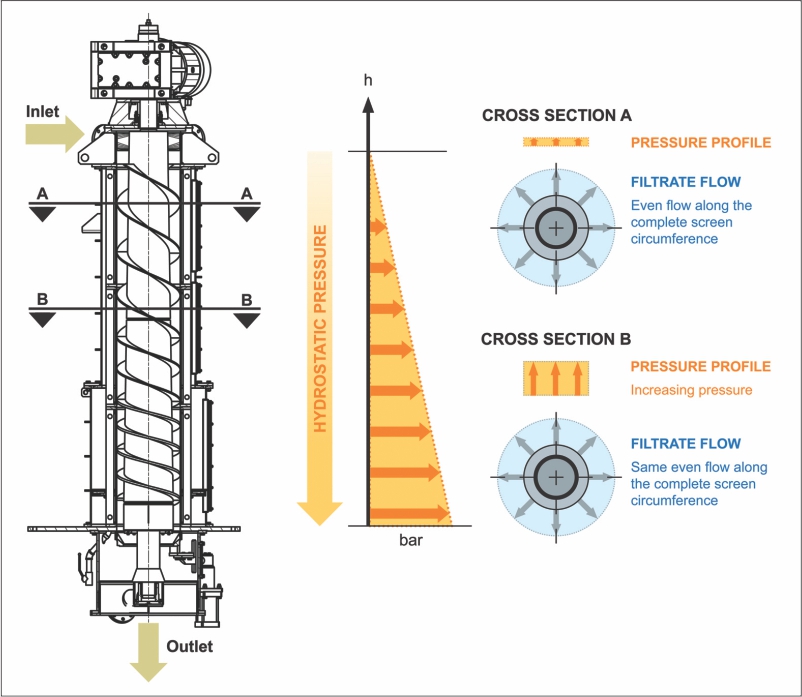

Often, the simplest ideas are the best. After evaluating several different design concepts to address these two limitations of the SCP in low feed consistency applications, the solution turned out to be a quite simple one: turn a horizontal SCP on its end and feed it from the top. In a vertical configuration, gravity works in a positive way: evenly distributing the pulp suspension across the full circumference of the dewatering screen and ensuring 100% filling.

In a VST, the pulp suspension is fed into the top of the machine and gravity transports the pulp downwards. The risk of plugging the inlet screen at low feed consistency applications is almost eliminated. Similar to the SCP, the VST has a conical shaft and decreasing pitch so the pulp is compressed and dewatered as it moves downward. The pulp suspension is automatically and consistently refilled into the area between screw flights. The rotating shaft moves the pressed cake downwards to the outlet casing.

A pneumatically controlled counter-pressure ring builds up the pulp plug quickly after startup and releases the pulp when the proper consistency is achieved. The ring pressure can be adjusted to fi ne-tune discharge dryness or can be quickly unloaded to avoid plugging. The result is that higher throughput can be achieved with the VST.

THE IMPORTANCE OF 100% FILLING DEGREE

The VST utilizes gravity to achieve 100% filling degree (100% of the screen area is used for dewatering). From top to bottom the filtrate flow around the complete screen circumference is very uniform (see figure 2). Similar to the horizontal press, hydrostatic pressure increases from top to bottom of the vertical unit. Unlike the horizontal design, the increased hydrostatic pressure actually improves the dewatering effect, since higher pressure is required as the pulp suspension’s consistency increases down the length of the screw. The hydrostatic pressure is enhanced by the design of the screw shaft with lower volume at the end. This creates additional dewatering forces and results in extremely uniform dewatering around the complete circumference of the screen baskets over the complete length of the machine.

ELIMINATION OF BENDING FORCES

For screw presses, it is important to maintain a very small gap between the screw flights and the screen baskets in order to achieve high dewatering efficiency. Mechanically speaking, the “dead weight” of the screw shaft itself plus uneven dewatering forces on the shaft of a horizontal SCP create bending forces and possibly deflection of the shaft. Mechanical designers make every effort to reduce the deflection to a minimum; however, the deflection can be significant for longer screw presses (up to 10 m shaft lengths). This deflection makes it difficult to maintain a small and uniform gap between the screw flights and screen baskets over the length of the shaft.

In the vertical configuration, the dead weight of the screw shaft has no impact and the screw operates with symmetrical axial forces. The opportunity for deflection is minimized and a uniform gap can be maintained over the length of the screw.

APPLICABLE TO ALL KINDS OF PULP

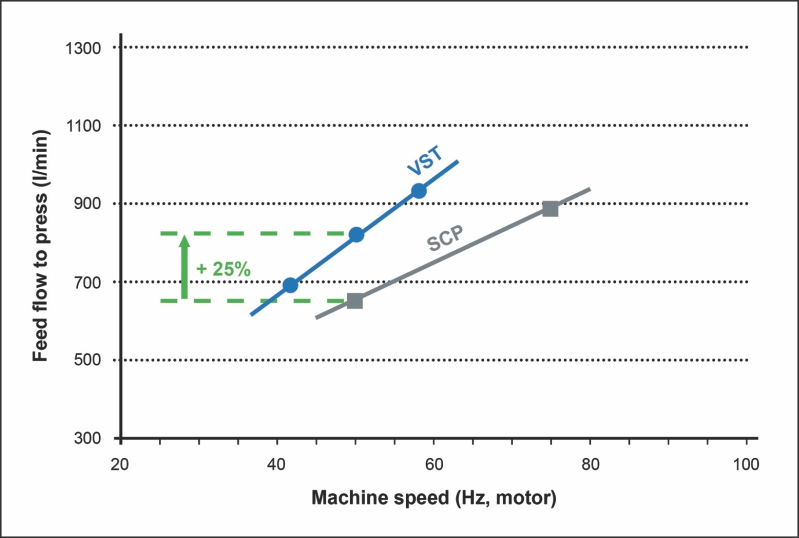

In 2015, a pilot VST was installed at the ANDRITZ pilot plant in Austria. The pilot machine was actually the smallest industrial size of the VST available, so that scale-up could be more readily evaluated. Various types of pulp have been tested in the pilot plant. The conclusion is that there are no limitations on the kinds of pulp that can be dewatered with the VST under various operating conditions. In a trial on hardwood chemical pulp, the VST was compared side by side with a traditional ANDRITZ Screw Press. Figure 3 shows the comparative results. At low feed consistency the VST demonstrated a 25% increase in throughput at the same outlet consistency over the whole range of operating speeds. Similar results have been achieved with other types of pulp, including recycled deinked and OCC.

Pilot trials have also shown lower energy demand for the VST, which would reduce the size of the motor and gearbox. The VST design is completely closed. It is designed with unique telescoping bottom filtrate housing and split screen baskets for easy maintenance. The screw shaft also has replaceable wear shoes to enable high efficiency over a long lifetime.

Main Benefits of the VST:

- Higher production – or higher output dryness at the same production – when compared with a traditional SCP of the same size

- Highest dewatering efficiency (particularly for low feed consistencies)

- 100% filling degree – screen baskets fully utilized to increase dryness and throughput

- Gravity-aided filling – uniform dewatering from top to bottom

- Uniform and consistent pulp discharge, which is beneficial to downstream processes

- Small space requirement/footprint

- Closed machine design

- Telescoping filtrate housing for easy maintenance access to screw and screens in the high-pressure zone