In 2020, ANDRITZ launched specialized HC refining technology for tissue production in China to tackle the challenges of surging pulp costs as well as to meet the demands of tissue producers looking for differentiation. Due to its remarkable success in operation, the technology was then steadily introduced to other Asian countries from 2022. In an interview with Paper Mart, Li Chunming, Technology Manager of Stock Preparation Systems, ANDRITZ China; and Alexander Gscheider, Director Product & Process Development RCF Global Assignment Technology, ANDRITZ give a complete overview of HC refining technology.

Paper Mart: With fluctuating prices of pulp, tissue manufacturers have been forced to increase the use of lower-priced raw materials such as hardwood pulp or annual plant fiber to reduce costs. Can you explain what challenges this move has had on the demands of stock preparation equipment? Also, what new products and processes has ANDRITZ developed as a world leader in the field of stock preparation?

Li Chunming: The need for tissue manufacturers to adjust the proportion of pulp has indeed brought new challenges to the stock preparation equipment. Currently, low-consistency refining is a prevailing practice in the industry. When the use of long fiber is reduced too much, it will compromise the paper strength, however, on the other hand, if the fibers are refined too much in order to improve web strength, this may result in negative effects such as higher fines content and lower bulk. Specifically, the increase in fines content will result in tissue dust, affecting consumer experience, thus lowering product image and quality. It will also bring serious dust pollution, resulting in a harsh working environment in the tissue manufacturer’s plant and have potential negative effects on workers’ health as well as increasing the risk of fire through potential dust explosions.

Lower bulk results in a worse consumer experience when it comes to touch and feel. Moreover, when producing toilet paper rolls with the same diameter, the manufacturer has to use more base paper, which results in lower profit margins.

With close cooperation between our global technology teams in China and Europe we have developed and launched a new compact high-consistency refining system mainly focusing on wood pulp short fiber and non-wood fiber. Compared to a low-consistency refining system, a high-consistency refining system can retain maximum fiber length as well as the strength of short or non-wood fibers by increasing short fiber’s contribution to paper strength, thereby reducing the consumption of long fiber.

Watch: JMC Paper Tech Launches New Subsidiary JMC Papers

PM: Compared with the traditional low-consistency refining system in terms of current fiber structure, what advantages does a high-consistency refining system have, for example, with improving tissue fiber form and tissue quality?

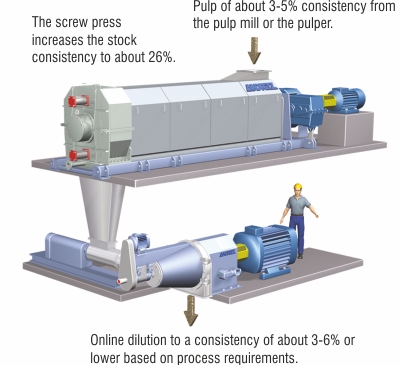

Alexander Gscheider: With the traditional low-consistency refining system, stock consistency is generally 3–5%. With ANDRITZ’s high-consistency refining system, we first use thickening equipment to thicken the pulp from 3–5% to about 26% and then send it to the refining zone of the high-consistency refiner through the screw feeder. In the refining zone, the pulp is primarily refined by strong kneading, friction, and other interactions between fibers in a refining gap smaller than 2 mm.

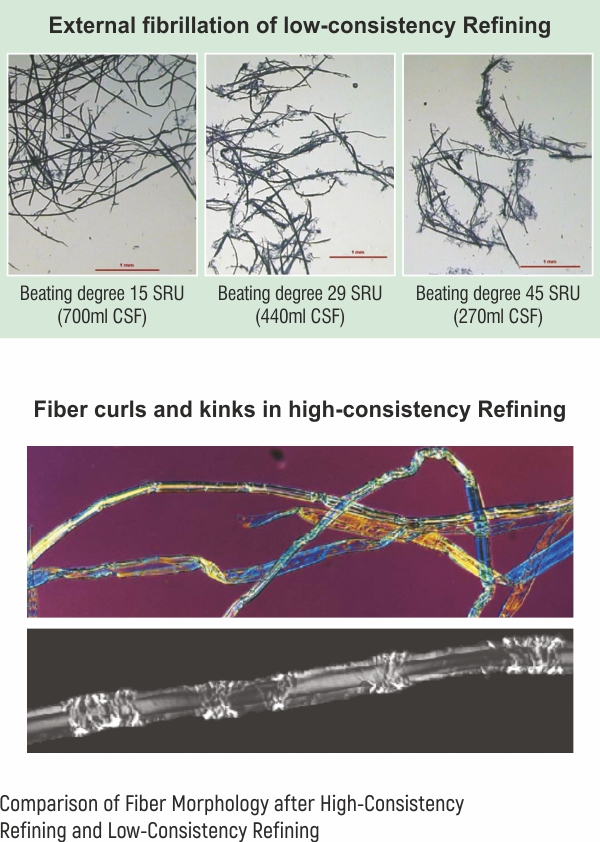

The current high-consistency refining system is mainly designed for refining lines of hardwood pulp and non-wood fiber in tissue manufacturing. These fibers are typically short, and one of the main advantages of a high-consistency refining system is avoiding fiber cutting as much as possible. The fibers treated by the high-consistency refiner feature internal fibrillation. Some fibers are kinked and curled, some are micro-compressed; however, they retain their length to the greatest extent possible. The fibers treated by the low-consistency refiner are characterized by external fibrillation. The fibers become straight, and some are inevitably cut and fibrillated. Therefore, the pulp processed with a high-consistency refining system has lower fines content than that processed to a similar beating degree with a low-consistency refining system.

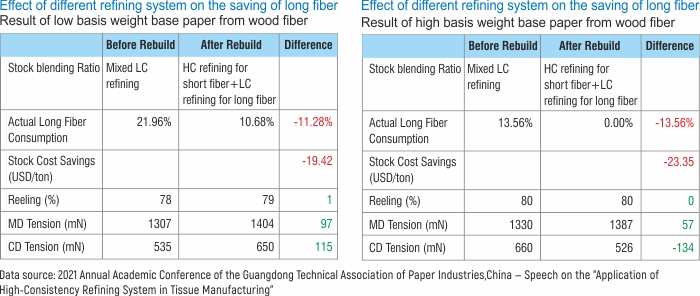

It has been proven in commercial applications that the adoption of a high-consistency refining system for short fibers can reduce the consumption of long fibers by up to 15%. The system can also meet the same requirements for paper strength while keeping or even improving the bulk, softness, absorbency, and other properties of papermaking.

PM: What difficulties did ANDRITZ overcome in the development of this compact high-consistency refining system? What is original about this process?

LC: As the demand for tissue has increased in recent years, especially for high-end tissue such as kitchen towels and facial tissues, the requirements for paper bulk, absorbency, and other properties have also become higher. Tissue manufacturers are making every effort to further reduce their costs while improving product quality and differentiation.

In terms of technology R&D, ANDRITZ has an established pilot plant in Austria and a stock testing laboratory together with a small pilot plant in China, thus greatly improving the efficiency of local R&D and service.

In 2019, ANDRITZ China received an inquiry for a customized high-consistency refining system from a papermaking base in Sichuan. Although we did not have the application of the technology at that time, the customer chose ANDRITZ as we have built trust through previous successful cooperations. After a series of simulation experiments and evaluations, we launched a compact high-consistency refining solution by integrating ANDRITZ’s outstanding products and optimizing the processes. In 2020, we officially delivered the first customized high-consistency refining system for tissue applications in China.

The core of the ANDRITZ high-consistency refining system is the screw press and the high-consistency refiner, which are compactly arranged on two levels. Thus, the system occupies much less space than its competitors and is much more user-friendly and convenient to maintain and operate.

Also Read: TNPL’s Sustainable Pulpwood Plantation Initiatives Nurture Environment

The screw press can increase the pulp consistency to about 26%, while the control system can maintain stable and continuous high-consistency discharge under different production capacities, and it can effectively prevent the screw press from clogging. The system uses counter-pressure to control the dryness by quick pressurizing or pressure discharging. The grooved screen basket can prevent pulp rotation, and the split-type screen basket for the high-pressure zone is easy to maintain. The screw flights are designed with wear-resistant shoes to extend its service life.

AG: The ANDRITZ high-consistency refiner adopts a simple, reliable hydraulic system with a Servo valve. It can adjust the gap between the plates via a programmable CNC electro-hydraulic drive, and thereby be highly adaptable. The lubrication and hydraulic systems of the high-consistency refiner are independent, which increases the accuracy of the gap adjustment and the stability of the gap. This is the key for ensuring optimum fiber quality.

The feed screw of the high-consistency refiner has hard faced sharp edged teeth on the feed side of the screw, so it can shred the pulp evenly to the greatest extent before the pulp enters the refining zone.

Combined with ANDRITZ’s patented high-consistency refining plates, the entire compact high-consistency refining system guarantees to provide customers with stable, consistent fiber quality and high-quality end products.

PM: An excellent product never fails the test of the market. At present, what economic benefits can the ANDRITZ compact high-consistency refining system bring to tissue manufacturers? How about its applications and future development?

LC: Up to March 2023, ANDRITZ has received 15 orders of high-consistency refining and preparation systems in China among which 13 have been started-up. In addition during 2022, ANDRITZ received its first order for HC refining for tissue in South East Asia. Manufacturers using this system can now process more diversified raw materials, including wood pulp, short fiber, bamboo pulp, bagasse pulp, and reed pulp, and can produce different paper grades such as facial tissue, toilet paper, tissue paper, and kitchen towels.

Although a high-consistency refining system requires more energy consumption compared with a low-consistency refining system, it significantly improves the quality of final products, such as bulk and feel. In today’s increasingly competitive tissue market, it can help a brand differentiate itself and, by reducing long fiber consumption, achieve considerable financial savings.

As an example: using a tissue machine with a width of 5.6 m, a design speed of 2,000 m/min, and an annual production capacity of 75,000 tons, customers can reduce costs by around USD 1.07 million annually with an average of 10% saving in long fibers and a conservative price difference between long and short fibers at USD 145 per tonne.

AG: Studies have shown that high-consistency refining systems can also be used for packaging paper, which is great news especially for the Chinese market as it now faces the challenges of a high proportion of LOCC with short fiber length and high requirements for product strength. In addition, there are also studies on the effects of long-fiber high-consistency refining technology in terms of air permeability and other properties of packaging paper, which also reveals a bright future for its application.