The machines will produce up to 120,000 tons of tissue per year and are designed for grammages from 12 to 42 g/m2 used for facial and toilet paper. Start-up is scheduled for 2019.

August 10, 2018

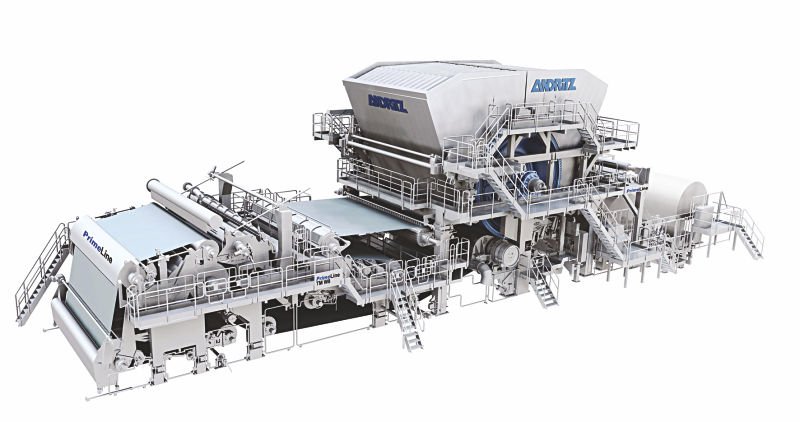

International technology Group ANDRITZ has received an order from Taison Pulp (Group) Co., Ltd. to supply two PrimeLineST W8 tissue machines, including stock preparation and automation systems, for their mill in Suzhou, Anhui province, China.

The two tissue machines have a design speed of 1,800 meters per minute and a paper width on reel of 5.6 meters, and they are equipped with the ANDRITZ PrimeControl automation system for an optimized production process.

The combination of an 18ft PrimeDry Steel Yankee with the steam-heated hood enables highly efficient drying with substantial energy savings compared to conventional dryer sections with cast Yankee dryers and gas-heated hoods. The steel Yankee will be manufactured at ANDRITZ China’s Yankee business center in Foshan, which offers customers state-of-the-art manufacturing, local field service, and quality management.

The scope of supply also includes the stock preparation system, comprising two lines to process short fiber pulp and a mixture of bamboo and long fiber pulp as raw materials, as well as the approach system and Disc Filter Savealls for fiber recovery. Market pulp bales are dissolved in ANDRITZ FibreSolve FSV pulpers, which enable efficient slushing without damaging the fibers. Six ANDRITZ TwinFlo double disc refiners achieve superior fiber properties with regard to fiber length and fibrillation. ModuScreen HBE screens protect the tissue machine and ensure highest runability.

This order once again confirms ANDRITZ’s strong market position as one of the leading suppliers of machines and systems to the Chinese tissue industry.