The PM14 will be designed to produce top-quality wood-free uncoated paper grades. The scope of delivery to Asia Symbol will also include an OptiFlo Gap headbox, an OptiFormer Gap forming section, an OptiPress Linear press section, and OptiRun Single and Hybrid drying sections with Valmet HiRun Web Stabilizers.

June 2, 2022

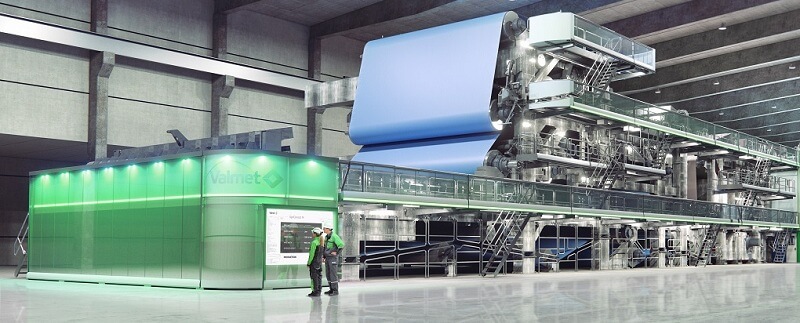

Shandong province, China-based Asia Symbol (Shandong) Pulp and Paper orders a fine papermaking line with stock preparation and extensive scope of automation from Valmet. The new high-capacity fine papermaking line will be designed to produce top-quality wood-free uncoated paper (WFU) grades. The new paper machine PM14 is expected to be started in 2023.

The order was included in Valmet’s orders received in the first quarter of 2022.

PM14 follows the long sequence of fine papermaking lines delivered by Valmet to the RGE Group, Asia Symbol’s parent company.

Mr. Steven Hung, Managing Director of Asia Symbol (Guangdong), says, “We chose Valmet to deliver Rizhao PM14 because of the excellent support and partnership we’ve had in the previous projects. We rely on both Valmet’s and our team’s experience and expertise to achieve another successful start-up together.”

Watch: Evolution of Paper Based Packaging

Mr. Mika Ollikainen, Vice President, Sales and Marketing, Board and Paper Mills, Paper business line, Valmet, says, “The long-lasting cooperation between Asia Symbol and Valmet is seamless. The Asia Symbol’s XinHui references have been operating reliably, and their performance is of world-class. Once again, we are building a world-leading WFU line both in productivity and quality. Valmet’s expertise supports Asia Symbol’s strong know-how of the WFU production. Our technology suits these types of fast and wide machines.”

Rizhao PM14 will be very similar to its predecessors (PM11, PM12, and PM13). The delivery will include a high-speed fine paper making line from stock preparation to reel and winders with air systems and clothing for the whole machine line. The stock preparation delivery will include a Valmet TwinRoll Press for pulp mill dewatering; stock lines for softwood, hardwood, and BCTMP (bleached chemi-thermomechanical pulp); bale handling with an automatic dewiring system; broke, white water and approach flow systems.

The delivery will also include an OptiFlo Gap headbox and an OptiFormer Gap forming section with shoe and blade technology for the best paper quality, an OptiPress Linear press section with two shoe presses for excellent profiles and dewatering capacity, and OptiRun Single and Hybrid drying sections with Valmet HiRun Web Stabilizers to ensure runnability at high speeds.

The drying section will be followed by an OptiSizer Film surface sizer with a supply system and an air turn device, an OptiCalender Hard calender for finalizing the end quality, an OptiReel Center center-driven reel, transfer rails, and two OptiWin Drum two-drum winders. The delivery will also include runnability equipment and a closed hood for the paper machine.

Also Read: Lemit Papers Orders Automation Technology from Valmet

The wide automation package includes Valmet DNA Automation System for process and sectional drive controls as well as runnability and condition monitoring and Valmet IQ Quality Control System. The delivery will also include paper machine clothing, spare parts, and consumables.

The paper machine with a 9,350-mm-wide fabric will produce wood-free uncoated, offset, and copying paper grades with the basis weight range of 50–120 g/m2. The design speed of the machine will be 1,800 m/min.