Grown to around 535,000 acres, IPAPPM’s farm forestry initiative provides a means of economic survival for many rural farmers and their communities. In an interview given to Paper Mart, Shyam Srivastava, Vice President – Purchasing & Farm Forestry, International Paper APPM Limited, talks about his company’s farm forestry initiative.

Here are a few excerpts from the interview.

Farm Forestry, International Paper APPM Limited

Paper Mart: How have you been able to reach 100 percent self-sustainability for your raw material requirement from a situation of scarcity of raw material?

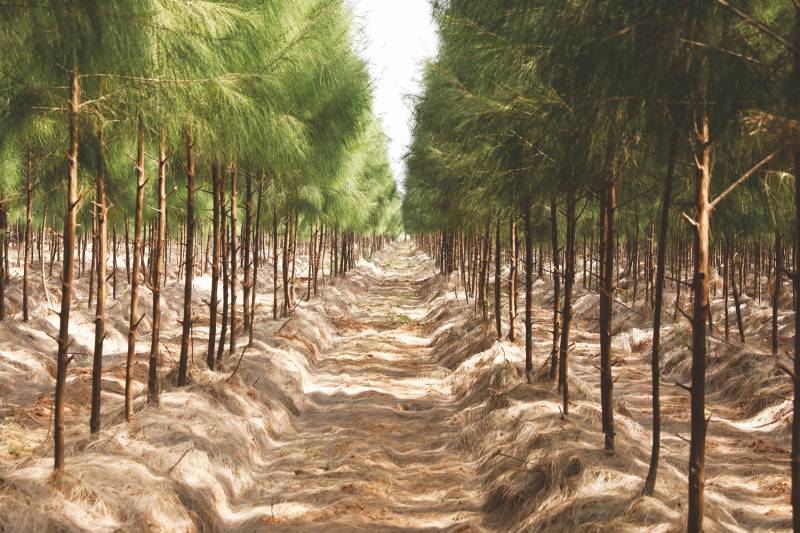

Shyam Srivastava: After the introduction of National Forest Policy 1988, International Paper APPM (IP APPM) realized that the pulp and paper industry would face serious challenges in procuring fibrous raw material. As a result, in the late 1980’s, the company embarked on an ambitious plan to generate fibrous raw material by coordinating with farmers to use their agricultural land, marking the commencement of farm forestry activities. Started in 1989, the farm forestry initiative proved to be a turning point in the history of IP APPM, spreading to many districts of Andhra Pradesh. In the following three decades, the company developed strong networks and resources in clonal sapling production and forestry extension. The company pursued forestry activities, building strong linkages with the local farming communities to ensure a long-term, cost-effective and sustainable raw material resource base in the vicinity of the mill. The program provided small farmers with means of survival and improved the socio-economic status of the farming communities.

Till 2018, the company’s farm forestry program ushered in the distribution of approximately 1.75 billion fast-growing Subabul and Casuarina saplings, which covered more than 2.5 lakh hectares of land. It helped over 70,000 beneficiaries with more than 125 million man-days of employment generation. The beneficiaries were provided with quality planting material and technical guidance at all stages of plantation facilitated by experts from the extension, R&D and production teams of the company.

PM: Water scarcity is a matter of concern for water-intensive industries, and the pulp and paper industry is a water-intensive industry. Your company uses the wood part of Subabul, Casuarina, and Eucalyptus for making pulp. Which of these trees uses the minimum amount of water for its growth? Which of these trees is the most economically advantageous tree?

SS: Subabul, Casuarina and Eucalyptus consume less water per unit of biomass gained as compared to many other tree species. The economic disposition of pulpwood species varies with the factors influencing their plantation and growth. In Andhra Pradesh, farmers plant saplings in accordance with the type of soil, traditional farming and rainfall patterns, demand for wood and other socio-economic factors.

PM: What has been the impact of the genetically superior clones of Casuarina and Eucalyptus that you have developed on plantation productivity and revenue generation for the farmers?

PM: What has been the impact of the genetically superior clones of Casuarina and Eucalyptus that you have developed on plantation productivity and revenue generation for the farmers?

SS: International Paper APPM has tied up with some national-level institutions for developing high yielding, genetically superior clones of Casuarina and Subabul to maximize plantation productivity and revenue generation for the farmer. Clonal propagation enables us to replicate the most vigorous mother plants with the desired characteristics, thereby generating two-fold benefits to the farmers who plant them. So, the benefit includes increased yield and better sale price realization. Compared to a bare-root seedling plantation, a clonal plantation’s advantage is reflected in its fast growth, high yield, disease resistance, better uniformity and improved quality of the produce.

PM: Do you think that paper mills in India have been successful in striking down the perception that paper mills are destroyers of natural resources?

PM: Do you think that paper mills in India have been successful in striking down the perception that paper mills are destroyers of natural resources?

SS: Paper mills have been quite successful in improving the tree cover outside the forest area in their procurement catchments. Forestry activities, plantation coverage of land and employment in areas where the mills are operating have grown substantially, something not witnessed in the past – when there were no paper mills. Paper mills have been able to motivate the farmers to plant trees on their otherwise barren and unproductive lands. Through their CSR activities, mills have furthered the interests of the local communities. Today’s pulp and paper mills are committed to enhancing the efficiency of their manufacturing operations, reducing their carbon footprint, and protecting the livelihood and promoting the welfare of local communities. The concerted efforts made by pulp and paper companies in this direction have started to erase the perception that paper mills are destroyers of natural resources.

PM: Have you been able to improve the productivity of degraded lands, control soil erosion and push moisture conservation through your social farm forestry program?

SS: Large tracts of lands in the coastal areas where we work are not fit for agricultural use. Farmers owning land in these regions have few livelihood options. Also, inland areas, including agricultural lands, suffer from soil erosion during periods of heavy rainfalls or strong winds. Our social farm forestry program encourages farmers to plant trees in agricultural and otherwise barren lands. We give quality Casuarina and Subabul clones or seedlings to these farmers. Plantation of these species prevents soil erosion. The structure of the soil is maintained by reducing desiccation through shading while tree rooting aggregates soil, thereby reducing chances of soil erosion or surface run-off. Leaf litter enhances organic matter, supports mulching and helps retain soil moisture. Because Casuarina and Subabul are nitrogen-fixing in nature, plantation of these trees on degraded land adds fertility to the soil and facilitates growth of other crops. By engaging farmers in agroforestry, our social farm forestry activities give protection to the land and increase its productivity.

PM: How have IP APPM’s research and development projects fuelled your company’s social farm forestry program?

PM: How have IP APPM’s research and development projects fuelled your company’s social farm forestry program?

SS: Our R&D projects will enable farmers associated with the company’s social farm forestry program to gain greater return on investment. These projects will increase the productivity of the land. The introduction of new and higher productive clones with shorter rotation cycles will ensure that the farmer gets extra income from the same piece of land. The social farm forestry program encourages the use of intercropping in pulpwood plantations with crops like groundnuts, sweet potatoes, gram, tomatoes, chilies and lady finger for additional income. IP APPM has tied up with some leading research institutions to leverage its expertise and technology and integrate them with the company’s extension efforts on the field. Through import of new clones or improved seeds, indigenous selection or breeding, establishment of clonal seed orchards and intercropping models, our R&D efforts aim to develop generations of clones with incremental growth prospects. Through our R&D efforts, we are striving to facilitate the transfer of the benefits of technology directly to the growers of pulpwood.

PM: Do you think that sourcing wood from farm forestry is a win-win situation for both wood-starved mills and farmers who want a steady source of income?

SS: Yes. Farm forestry is definitely a win-win situation for both. Plantations not only ensure a more stable wood supply, but also scale up job creation and protection of livelihood in the region. Casuarina grows well in sandy soils along the coast, soils that are not conducive to the growth of food crops. Farmers have also found that the income they earn from growing Casuarina is higher than the income they receive from otherwise marginal or degraded farmlands. This species is also a nitrogen fixer – that’s an added advantage. Additionally, crop rotation is short enough – typically four years. And that ensures regular cash flow. There is no wastage of the plant, as the whole crop is quite old for separate purposes. The larger stems are sold as construction poles, the smaller stems for pulpwood and the branches for local fuel wood. Even the stumps are dug up and used as high-calorific fuel for brick making. Surely, farm forestry is highly beneficial for both paper manufacturers and farmers.

PM: Do you think that India’s agroforestry policy is a step in the right direction?

PM: Do you think that India’s agroforestry policy is a step in the right direction?

SS: The Indian Agroforestry policy 2014 aims at removing restrictive legal provisions for harvesting and transportation of trees planted on farmland and providing mechanisms for quality planting material, infrastructure and price. This is a welcome move from the government. It incentivizes farmers to adopt agroforestry and grow wood on farmland for better returns. While the agriculture crop will ensure food security of the nation, the tree cover on agricultural land will help achieve 33 percent of forest cover as envisaged in the National Forest Policy. At the same time, tree plantations along with agriculture will help in meeting the demand for firewood as raw material for paper, real estate, plywood, energy plants, furniture, firewood and other wood-based industries. It will also generate large scale and perpetual rural economy which will generate millions of man-days of employment. In addition, harvesting of trees on agricultural lands will generate additional income for the farmers. This will also help to hedge any uncertainty in demand and supply of agriculture crops. When we look at the trees outside the forest cover, we find that there is significant increase in the pulpwood plantation area in the catchment of paper and pulp mills. This reflects the demand for agroforestry among the farmers. At this juncture, motivating farmers to go for agroforestry is the only way to build pulp and paper business sustainably.

PM: What are your company’s future targets in the area of farm forestry?

SS: Our future targets in the area of farm forestry are aligned with the fiber and forestry strategy for building a long-term pulpwood security at an optimum cost in the catchment area of IP APPM’s mills. Under this strategy, we are targeting to maximize our sourcing within 150 km of the mill in coming years. We have formulated certain objectives in the area of research and development related to new clones and seedlings of Casuarina and Subabul. The company is also aiming to achieve certain targets in areas such as reduction in plant production cost, management of the gene bank, development of best cultural practices for Casuarina and Subabul under various edaphic conditions, development of low-cost harvesting equipment and new clone or seedling release with incremental productivity.