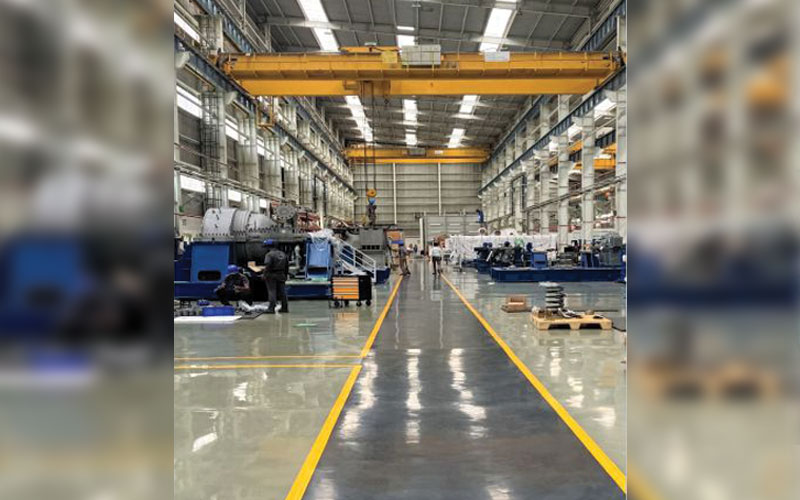

With decades of expertise in manufacturing engines and turbomachinery in India, MAN Energy Solutions is highly regarded by Indian customers for its exceptional quality. The state-of-the-art facility in Bangalore, equipped with the latest production infrastructure and boasting a workforce of over 300 skilled employees trained in turbomachinery production, is poised to commence production of the latest RT56-1 single-stage vacuum blower in India, aligning with the “Make-in-India” policy.

The paper industry is undergoing a transformation to address mounting energy costs and the imperative to diminish its carbon footprint. Companies are refining production systems for enhanced competitiveness while emphasizing energy savings, sustainability, and expansion into novel product lines. In 2022, board and packaging paper production exceeded 265 million tons, with a projected annual growth rate of 4.6%. Sustainability is increasingly vital, leading to the adoption of decarbonization technologies and a focus on energy optimization in papermaking. Notably, dewatering the paper roll, a key manufacturing stage, consumes 20-25% of total electrical energy through conventional liquid ring pumps.

TURBAIR® vacuum systems, developed by MAN Energy Solutions in Switzerland, prioritize energy efficiency and sustainability. Unlike conventional water ring pumps, prone to wear and efficiency decline over time, these blowers ensure consistent performance. In conversion projects, they typically yield energy savings of 40% to 60%, consuming up to 30% less energy than traditional pumps due to their friction-reducing design.

Watch: Top Paper Companies 2023

Engineered for efficient operation across various conditions, including partial loads, TURBAIR® blowers offer potential additional energy savings of up to 30%. Equipped with frequency-controlled drives, operators can flexibly adjust air volume and vacuum levels to match the paper machine’s needs. This not only prevents unnecessary energy loss from over-expansion but also potentially reduces energy usage by up to 20%, depending on process requirements.

Moreover, TURBAIR® technology eliminates the need for sealing water, cutting costs and reducing environmental impact. By obviating the need for sealing water, these blowers foster a more sustainable and eco-friendly operation. Manfred Dobler, Head of Paper Industry at MAN Energy Solutions, mentions, “TURBAIR® vacuum systems excel in efficiency and reliability. A significant advantage is the ability to utilize hot exhaust air from the blowers with a heat exchanger, further enhancing energy savings. Typically, 70% to 80% of the blower’s drive energy can be recovered through waste heat.”

“Considering the potential savings mentioned, paper manufacturers can significantly reduce energy consumption of the vacuum system by up to 80%.”

Versatile Vacuum Blower Solutions

To cater to diverse requirements in papermaking, we offer single-stage RT or multi-stage RC blower types in various sizes:

Single-stage RT blower:

Ideal for most paper machines, particularly those in India producing up to 300 tons per day, the single- stage RT 56-1 vacuum blower addresses all dewatering and felt conditioning needs. Its broad operational range enables customers to adjust GSM and vacuum levels while maintaining minimal power consumption across all production cycles.

The RT vacuum blower boasts a capacity range of 200 to 1,450 m3/min, with a pressure of up to 62 kPa. With automatic outlet regulation, the flow rate can be dynamically tailored to paper machine requirements. This adaptability renders the RT series particularly suitable for felt conditioning in tissue production.

Considering the potential savings mentioned, paper manufacturers can significantly reduce energy consumption of the vacuum system by up to 80%.

Also Read: Santosh Starch: The Leaders in Innovative Specialty Starch Solutions

Multi-stage RC blower:

The RC vacuum blower offers extensive capabilities, spanning from 180 to 2,800 m3/min, and is equipped with up to four suction nozzles. This configuration facilitates efficient operation across varying vacuum levels in the screen and press sections. Precise vacuum control is achievable within a range of 55 kPa to 78 kPa.

Tailored for demanding environments, the RC blower excels in systems utilized in graphic paper, cardboard, or pulp production. Its multi-stage radial design ensures consistently high vacuum levels, delivering a reliable vacuum system in compact size.

“At MAN Energy Solutions, we are committed to the promising growth opportunities in India and have full confidence in its highly skilled workforce. We firmly believe that the top-notch vacuum blowers manufactured in India will not only meet the needs of our domestic customers but also exceed expectations across the region,” remarks Manfred Dobler, Head of Paper Industry at MAN Energy Solutions.