“We are in the midst of establishing a technology centre in Europe to bridge the gap of technology and requisite manufacturing information to the customers as per Industry 4.0 concept. In fact, we have definite plans to establish the same in the year 2021.”

Executive Director, Servall Engineering Works Pvt. Ltd.

In an interview with Paper Mart, Mr. Shreeman Ram, Executive Director, Servall Engineering Works Pvt. Ltd. presents his views on the recent developments at the company, their key strengths, future growth strategies, and how the government initiatives such as – “Make in India” and “Atma Nirbhar Bharat” are anticipated to propel the growth of the Indian Paper Industry.

Paper Mart: To start with, could you please shed some light on new developments at Servall Engineering Works?

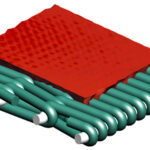

Shreeman Ram: In the quest of excellence and to remain a trusted partner in the pulp and paper industry worldwide, we have acquired new technology and knowhow from Europe and have ventured into complete drying solutions as steam & condensate, hood & pocket ventilation, web stabilizers and air dryers. Furthermore, on various requests and inputs from the market worldwide, we have re-started recycled fiber pulping line from conveyor to approach flow.

With the advent of Industry 4.0, concept, Servall is in the middle of establishing a technology centre in Europe to bridge the gap between traditional and modern paper making. Also, it is to be noted that the partnership with the Indian paper industry is not only limited to complete paper machine line or fiber line, we are aggressively looking to serve our esteemed customers for unit equipment, sections, spares and rebuild.

PM: What do you think are the key strengths of the company that enables you to make your mark in the paper Industry?

SR: Much of Servall’s success can be attributed to its tradition of keeping abreast of the technological developments and constant innovation. Towards this end, the company has entered into technical collaborations and license arrangements with world leaders in pulp and paper machinery segment.

Servall with its large manufacturing facility — from the state-of-the-art foundry to final assembly, its manufacturing processes are under stringent quality controls to cater requirements of the customers. Our manufacturing processes are approved by TUV and ASME, and all products go through rigorous quality inspection before shipping to the customers.

“Advanced hardware and software, cutting edge technology and skilled engineers and designers have ensured that Servall’s machines are globally renowned for their high performance, ruggedness and durability.”

Furthermore, Servall’s design and project department is a key pillar of strength for the company. Advanced hardware and software, cutting edge technology and skilled engineers and designers have ensured that our machines are globally renowned for their high performance, ruggedness and durability. The engineering division includes a full-fledged CAD centre equipped with the latest 3D modelling analysis and engineering software.

PM: What are your future plans and growth strategies for the coming years?

SR: We are in the midst of establishing a technology centre in Europe to bridge the gap of technology and requisite manufacturing information to the customers as per Industry 4.0 concept. In fact, we have definite plans to establish the same in the year 2021.

PM: The government initiatives such as “Make in India” and “Atma Nirbhar Bharat” are anticipated to drive the demand and propel the growth of the Indian equipment manufacturers. How do you perceive the kind of contribution these initiatives could make to the overall growth of the Paper Industry?

SR: If you take a look at the various projects that have been launched in India, you will notice that there are very few mills that have the resources to import full machines from Europe. So, a lot of these machines are being made in India to reduce the cost. We, at Servall, have always practiced “Make in India” since the inception (i.e. since 1970) and the majority of our projects are based on in-house manufacturing.

“With the implementation of the Industry 4.0 concept and technology centre, we shall be wholly self-reliant (“Atma Nirbhar”) by the year 2022.”

Moreover, with recent developments and requirements to declare the country of origin is also slowly impacting the paper industry to embrace and encourage the “Make in India” initiative. Our manufacturing process and final assembly are approved by TUV and ASME which further testifies our assertion of bringing quality products to the customers. With the implementation of the Industry 4.0 concept and technology centre, we shall be wholly self-reliant (“Atma Nirbhar”) by the year 2022.