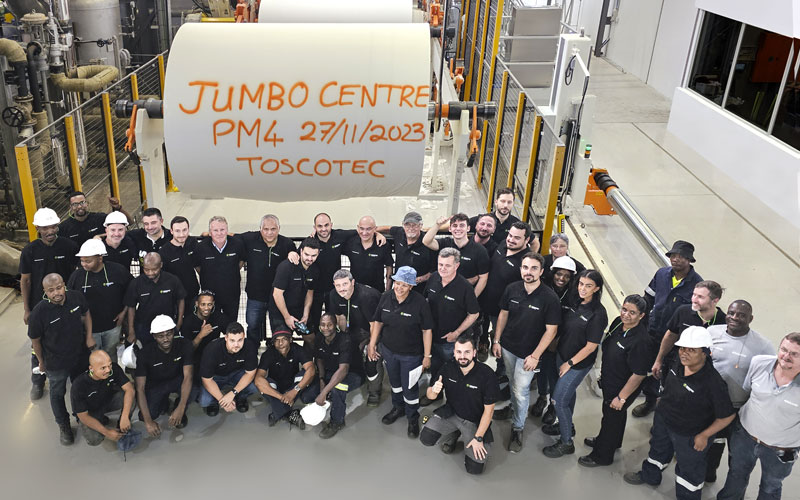

The Johannesburg facility of South African tissue producer, Jumbo Centre starts up the AHEAD 1.8 machine provided by Toscotec. It has a sheet trim width of 2,750 mm, an operating speed of 1,800 m/min, and a production capacity of more than 30,000 TPA.

Dec 06, 2023

Recently, an AHEAD 1.8 tissue line supplied by Toscotec has started up at the Johannesburg facility of a South African tissue producer Jumbo Centre. This is a repeat order for Toscotec after the successful installation in 2020 of another complete tissue machine at the same mill. The AHEAD 1.8 machine has a sheet trim width of 2,750 mm, an operating speed of 1,800 m/min, and a production capacity of more than 30,000 TPY. It is equipped with a new-generation design TT NextPress shoe press, a third-generation TT SYD steel Yankee dryer, and a high-efficiency TT hood. The scope of supply covers the complete production line from the bale handling and stock preparation systems to the electrification and control system of the tissue machine. The associated services include detailed engineering, erection supervision, commissioning, training, and start-up.

Watch: MLM Group to Import 25,000 TPM Forest Products

Itzik Nikfard and Rafi Nikfard, Directors of Jumbo Centre, said, “This investment marks a new important stage of expansion for our business. The choice of technology is key in supporting the continuous growth and success of our SnowSoft brand. Toscotec’s machines deliver premium tissue quality, high production efficiency, and energy savings which equip us to succeed in the market.”

Sean Nieuwenhuys, Chief Operating Officer, remarked, “I have been acquainted with Toscotec for several years and have been involved in the start-up of three tissue machines with Toscotec as the key technology provider and partner. Toscotec is known for fulfilling its technological commitments and helping clients achieve its efficiency and quality goals. I am confident that with this latest project, our business will reap the benefits of numerous technological advancements and improved energy efficiency. We anticipate that the new generation shoe press will enhance the bulk and softness of our products and improve the overall efficiency in our converting operations”.

Also Read: Union Paper Mills Orders Automation & Quality Control Systems from Valmet

Matteo Giorgio Marrano, Toscotec Sales Manager, said, “Toscotec is proud to support Jumbo Centre in their decision to continuously upgrade their tissue making technology over the years to properly support their growth in the regional market. They moved from simple machinery to our energy-efficient MODULO-PLUS machine and now to this state-of-the-art AHEAD tissue line featuring Toscotec’s best-in-class energy efficiency technology. An impressive journey in just a few years’ time.”