Keeping sustainability at the heart of its business, Trident Paper is a leading manufacturer of wheat straw-based paper, thereby contributing to the circular economy. It is focusing on the B2C segment and moving up the value chain. Trident is eyeing ‘notebooks’ as an emerging sector. Committed to innovation, quality, and customer satisfaction, it is actively working on expanding both its capacity and product range. In an interaction with Paper Mart, Mr. Samir Joshipura, Group CEO, Trident Group, and Mr. Srinivas Sapher, Chief Marketing Officer, Trident Paper, talk about their recent innovations and product developments, giving insights about the Indian and the global paper market.

Paper Mart: Trident is a leading wheat straw-based paper manufacturer. What inspired you to enter this segment?

Samir Joshipura: At Trident, we are proud to be an agro-based paper manufacturer, specializing in producing paper that is both environmentally friendly and sustainable. We refer to it as ‘Good Paper’ because it not only benefits the environment but also supports farmers by offering them an alternative to burning agro-waste at the end of the crop season. This initiative significantly reduces carbon emissions and saves approximately 1.8 million trees annually.

Srinivas Sapher: Keeping sustainability at the core, Trident Paper has evolved into a responsible business. I attribute this to the vision of our promoters, who built our paper business with wheat straw (Stubble) left over from the harvesting as the raw material which would have otherwise been burnt causing pollution. This helped us to create a circular economy, with farmers no longer considering wheat straw as waste, and instead generating additional income from the same. So, it’s apparent that we have positioned ourselves as a responsible paper company with our Good Paper that is good for life and our future.

PM: What is your production capacity for this segment and how would you describe your position in the market?

SS: At present we have two paper machines in our unit- PM1 and PM2, yielding a production capacity of about 480 TPD. We are strongly looking at the B2C segment, moving up the value chain by making paper products. We have been growing consistently since then. For instance, demand for our copiers in North India is very strong. We have started producing notebooks and other paper stationery as well, and we are looking forward to scaling it up. The priority is catering to the B2C segment. In market distribution, we have a strong network in the north, which we are slowly taking to the west and east. The mandate is to set up notebook distribution as a separate vertical.

PM: Please discuss some of the innovations and recent developments at your place. What are your USPs?

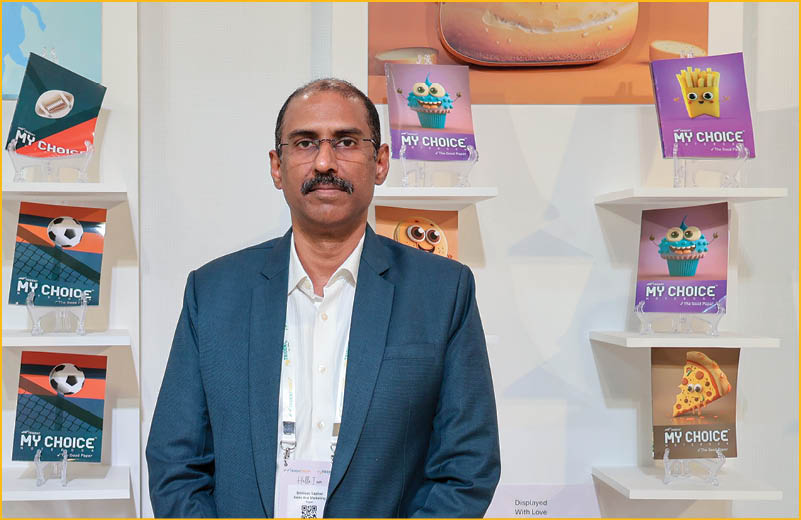

SJ: Our recent notebook designs, particularly aimed at younger users, have seen remarkable success, and we are committed to expanding our presence in this segment to become a market leader. With the introduction of our new paper, Crystal 9, and the launch of a loyalty program for our channel partners, we are confident that our brands—Spectra, My Choice, and Royal Touch—will drive increased market share and be the preferred choice for consumers while helping our channel partners grow profitably.

SS: The biggest innovation was when the owners put up a plant using wheat straw as its core. We were amongst the first manufacturers to make copier paper from wheat straw. Today we look at notebooks as an emerging segment. We want to get more into consumer-facing business. Our brand, ‘My Choice’, has received overwhelming response.

Our approach to technology focuses on delivering exceptional product quality to clients and consumers. It’s not about revolutionary concepts, but rather enhancing the value we provide, as can been seen with the paper that we use for our notebook range where we use 60 GSM paper; which means a thicker paper for better writing experience. In fact, we are the only branded player to do so even if it means being more expensive than competitors. The emphasis is to deliver superior quality, which is aligned with our brand’s promise. Moreover, we’re committed to innovation, quality, and customer satisfaction, and driving our growth and expansion.

Watch: In Pursuit of Lesser Water Footprint

PM: How do you ensure the quality and consistency of your paper products?

SS: The key is technology, and the promoters have been very clear about this. The fact that we have SAP right across all the operations explains for us, ‘standard means standard’. There is thorough automation at each level and a lot of transparency is built into the system. We are one of the very few companies where the customer has absolute clarity; we do reconciliations every month. Automation and the whole philosophy are ingrained in the people who are running the machines. Whether it is the backend or the frontend, there is technology that is running behind it.

PM: Tell us about your export markets? How is the overall volume split up between exports and domestic consumption?

SS: We have our footprints in more than 30 countries across the world. While majority of our exports are in African region and Middle East, of late we had started consolidating our presence in US, Europe and New Zealand along with the SAARC countries. Depending on the markets, we customize our products. In India, there’s a misconception that brighter paper is better. However, the European and several other markets prefer a slightly off-white tone, as prolonged reading causes eye strain due reflection of reading lights from the paper.

Accordingly, we have developed a new product, Pearl line, which is “Soft for eyes” and which we feel has good market potential in the European and the US publishing markets. The success of the product is such that we are experiencing capacity constraints, and we are in a sold-out position. To keep up with diverse demands, we continue to develop new products and tailor them. In fact, we are one of the few companies across the world which supply copier paper on non-laminated wrappers and hence completely sustainable.

Our export revenue is approximately 5 to 10 percent of the total revenue, and I’m confident that the numbers will change as we are driven by innovation.

PM: Amongst the wide product portfolio, what are your best performing ones?

SS: ‘Spectra’ is our flagship copier brand which enjoys the highest demand, featuring a 75 GSM in domestic markets & 75 GSM / 80 GSM in International market. It ensures a perfect balance between durability and flexibility, making it ideal for various applications. Well known in the Middle East and Africa, especially in Kenya and Tanzania. I must say it is one of our mainstays as a brand.

Another segment, Maplitho, is the jack of all trades. Our “Diamond” line maplitho, ranging from 60-150 GSM, is extensively used in printing and publishing houses. Its versatility and high-quality finish make it a preferred choice for various printing needs, ensuring crisp and vibrant results every time.

Also Read: Ruchica Garg Kumar: From ‘Helicopter Mom’ to Industry Trailblazer

PM: What challenges do you encounter as a paper manufacturer?

SS: While working directly with farmers, we’re also partnering with NGOs to educate them, as we’re in a symbiotic relationship. If farmers compromise, the product suffers, and both parties lose. Procuring consistent, high-quality raw materials poses a challenge.

Another challenge is the highly capital-intensive characteristic of the paper industry. From an industry perspective, we urge the government to provide stronger financial support through policies, as this sector also benefits farmers and society at large. The significant upfront investment, with returns materializing after three years, makes it challenging to create a viable commercial proposition.

PM: The paper industry is often branded as ‘water guzzler’. How water efficient are your mills?

SS: As mentioned earlier, sustainability is at the heart of our business. It encompasses not only water conservation but also responsible chemical management. Our on-site effluent treatment plant enables us to recycle and reuse water, further reducing our water footprint. We have our own sumps where we store rainwater, however, it is insufficient. But our unwavering goal is to save as much water as possible by reducing water consumption or doing more with little.

We have significantly increased our renewable and clean energy share, with the installation of 12.53 MWp rooftop solar during Q1 FY25, bringing the total solar capacity to 40.9 MWp. The power generated from solar power projects is consumed for manufacturing facilities located at Budhni, Madhya Pradesh resulting in a considerable reduction of carbon footprint.

Mr. Samir Joshipura,

Group CEO, Trident Group

PM: Running a paper company needs a highly diverse workforce, given that mills are located in rural areas, while the offices are in the cities. How do you address the challenges?

SS: The Trident family has been running Takshashila. It’s one of the programs where every year we take students and train them for about a year, providing them with a stipend and eventually retaining them. The program operates on the principle of “Learn, Earn, and Grow,” aiming to uplift individuals from rural areas by providing them with valuable opportunities. Each year, the program welcomes new participants from these regions, offering them a starting salary of 12 lakhs. This initiative not only supports financial growth but also fosters personal and professional development, empowering participants to achieve their full potential.

Our factories are in the rural areas, but we have a lot of employees from cities who have been stationed there. It is possible since we have created a good ecosystem comprising housing to sports and medical facilities, to mention some.

PM: Give insights about the Indian paper industry, the challenges it faces and what support it expects from the government.

SS: The industry has a lot of potential. Post-COVID, a lot of paper manufacturers entered the packaging segment with the rise of e-commerce. India happens to be one of the few bright spots globally where paper consumption is rising 6-7% annually. With FTA and other agreements, a lot of cheap paper is being imported, which makes it difficult for the mills to sustain their quality. Another big challenge is the cost structures. In India, costs are higher due to various reasons. It could be sourcing raw materials or taxes. We request the government to be more proactive by offering support, such as financial incentives, lower interest rates, and commercially viable incentives.