As part of the Process Line Package (PLP), Voith assumes full responsibility for the project.

October 10, 2019

Ilim Group, Russia’s largest pulp and paper producer with an annual production volume of more than three million tons, will significantly expand its production capacity in a project now underway. As part of an extensive investment program, the company plans to produce up to 600,000 tonnes of kraftliner per year at its new plant in Ust-Ilimsk, Eastern Siberia, starting in 2021. The key partner in this project is the technology group Voith, which is working with Ilim Group on this scale for the first time.

The experts for the entire papermaking process ensure that the plant in Siberia starts up safely, on schedule and with precisely coordinated components. The PLP reduces the number of required interfaces and contact persons and simplifies the entire project handling, which ultimately also reduces costs.

As a full-line supplier, Voith is able to provide all system components including screens for each section, as well as comprehensive Papermaking 4.0 digitizing technologies. In addition, the globally positioned group is responsible for the electrical equipment and the entire drive system of the plant. A comprehensive training program on the new machine is also part of the project scope.

“Voith is partnering with Ilim Group in this historical and outstanding project. It will become a milestone for the Russian pulp and paper industry, and we are proud to contribute with our deep experience and latest innovations,” says Christoph Müller-Mederer, President Projects EMEA at Voith Paper.

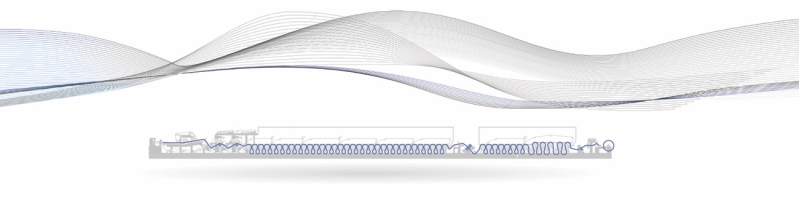

The centerpiece of PM 1 in Ust-Ilimsk is a XcelLine of the latest generation. With a wire width of 10,300 millimeters, the Ilim Group plans to produce up to 2,150 tons of kraftliner per day with basis weights between 80 and 175 grams per square meter. This will make the new machine the most powerful of its kind in the world. The production speed of 1,200 meters per minute also represents a top performance.

OnCare.Health and OnCare.Asset as well as OnEfficiency.Strength are among Voith’s Papermaking 4.0 digitalization technologies that ensure consistently high product quality and reliably efficient manufacturing. In Ust-Ilimsk, OnCare.Health monitors the current status of the system at all times, registers even the smallest malfunctions and their causes, alerts the papermaker and independently works out optimization measures. In combination with the intelligent maintenance management system OnCare.Asset, this enables a significant increase in machine availability.

In addition to the record-breaking XcelLine machine, two BlueLine stock preparation systems are also included – one for hardwood pulp, the other for softwood pulp. They ensure exact compliance with the composition of the pulp. Voith’s technology thus sets the course for maximum product quality right from the start of the process.

The preassembled equipment will be erected directly at the construction site in Ust-Ilimsk. In addition to the XcelLine and the BlueLine, components supplied by Voith will include a FlowJec dosing system for additives, the former section with two Fourdrinier machines equipped with MasterJet Pro F, a ModuleJet II and DuoShake, EcoCal hard calender, the drying section with CombiDuoRun dryers and a Sirius reel with EcoChange and VariFlex Performance winder. The delivery of the 79-ton Nipco-P roll represents a particular challenge for the project.