Bry-Air (Asia) Pvt. Ltd.

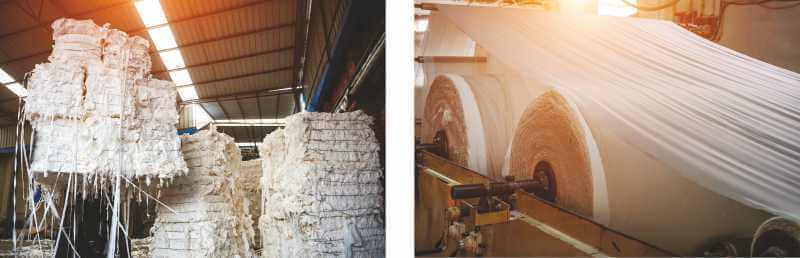

Paper Industry is one of the high priority industries having a bearing on socio-economic development globally. In India, the industry plays a vital role in overall industrial growth and is one of the fastest-growing industries. The paper industry in India consists of small, medium and large-sized paper mills manufacturing different grades of paper as per market needs. In order to obtain a good end product, the pulp & paper industry goes through multiple processes. The quality and characteristics of paper are the flagships of any manufacturer. If the quality of the paper is excellent, it leads to high revenue along with satisfied customers. But achieving the desired end product with unmatched quality is an arduous task. The key to success is optimal climate control in the production and storage stage. Pulp and paper manufacturing is a cumbersome process involving a lot of critical steps, factors such as high temperatures, high humidity, and constant water ingress are particularly challenging and can adversely impact productivity.

To define, paper coating is a method in which the paper is coated with a specific compound or polymer such as kaolinite, calcium carbonate or bentonite, to impart desired characteristics in the paper which enhances the quality of performance and printability. However, high solids and viscosity are needed to obtain a good printability and uniform coating layer. Paper is naturally hygroscopic, making it dimensionally unstable and vulnerable to temperature and humidity changes. Hence, it is quite important to maintain optimal air quality and humidity levels should be controlled. It’s one of the critical parameters to ensure smooth and efficient operations.

Once produced and reeled, the paper can be exposed to ambient conditions at the end of the paper machine for a considerable period of time. When the desired level is maintained throughout the manufacturing process, the moisture in the paper maintains not only the flexibility of the product but also leads to stable production and packing. Low humidity in the slitting area will cause moisture losses to occur; these losses will take place very quickly. The paper sheds most of its moisture during the manufacturing process; it tends to retain moisture, particularly along the edges, during packaging and storage.

The other prevalent factor which needs to be given equal importance while manufacturing is the corrosive gases. In the pulp & paper industry, there are different chambers associated to develop the products, such as DCS rooms, recovery boiler control rooms, pulp milk control rooms, fiber line control rooms, evaporated line control rooms, and others. These control rooms get exposed to a wide variety of corrosive chemicals like chlorine, sulphides, hypochlorite and several other similar corrosive substances as products react at various stages while processing the pulp. The control room equipment is to be protected to achieve optimum reliability and productivity of the paper and pulp processing as high eminent chemicals and gases such as hydrogen sulphide, sulphur dioxide, carbon monoxide can bring the server in control rooms to a halt.

The protection of such rooms should be carried out by providing cleaned pressurised air; it is advisable to provide air leakage ports, again at the room ceiling level. By doing this, the MCC room shall not only be protected from corrosion but also enough air would be thrown out of the room to extract the generated heat.

When it comes to controlling the humid environment, the ambient conditions/production environment plays a major role in maintaining the humid situation along with the weather conditions. While the weather conditions are unpredictable, a minor deviation in the environmental conditions can lead to a high level of humidity. Bry-Air Dehumidifier can lower the moisture content of the surrounding air in the manufacturing, packaging, and storage areas to the desired level and help upgrade the quality of the paper in terms of its performance and producing the final product.

Gas Phase Filtration System is the most ideal and cost-effective system to deal with any issue of corrosion in various control rooms. It is the key to airborne molecular gaseous and particulate contamination removal. Bry-Air Gas Phase Filtration Systems (GPF) Systems provides an optimum solution for efficient removal of air-borne contaminants causing corrosion, bad odour and harmful gases from the atmosphere. The systems are designed keeping in view various existing parameters such as contaminants presence and their concentration, airflow, space availability, and standard legacy systems in the contaminated atmosphere. The wide range of chemical media and macro-porous chemical filters are most suited for the efficient removal of almost all types of harmful contaminants.

Therefore, having gas phase filtration solutions, and desiccant dehumidifiers moisture control solutions are a blessing for the pulp & paper industry operators preventing them from the hassle of corrosion and abysmal product.