The tissue capacity of Vietnam’s Xuong Giang Paper reached up to 72,000 TPA after getting ANDRITZ’s new tissue machine, which can produce high-quality facial, toilet and towel paper with a speed of 1,300 m/min and a paper width of 2.85 meters.

Apr 5, 2024

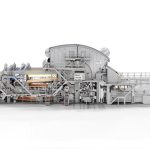

International technology group ANDRITZ has successfully started up its second tissue production line at Xuong Giang Paper in Song Khê – Nội Hoàng Industry Park, Bắc Giang Province, Vietnam.

A statement issued by ANDRITZ says that with this new line, Xuong Giang Paper’s tissue capacity will reach up to 72,000 tonnes per year.

Like the machine supplied by ANDRITZ in 2020, the new PrimeLineCOMPACT S 1300 tissue machine processes virgin pulp to produce high-quality facial, toilet and towel paper with a speed of 1,300 m/min and a paper width of 2.85 meters.

Watch: Top Paper Companies 2023

It is equipped with a 12-ft. PrimeDry Steel Yankee with a steam-heated hood ensuring highly efficient drying and energy cost savings. ANDRITZ has also supplied fabrics and rolls and a tailored automation system, including PrimeControl machine and distributed control systems.

The stock preparation plant is split into separate systems for short and long fibers with high-consistency (HC) refining to achieve better fiber quality in terms of strength, softness and absorbency compared to conventional low-consistency systems. HC refining also allows to save long fibers and thus reduce production costs.

It is the first time that such an HC refining system has been installed in tissue production in Southeast Asia. ANDRITZ’s scope of supply also included an approach flow system, fiber recovery and broke handling equipment as well as pumps.

Also Read: Ekman Group Acquires Allan Morris Recycling Facility Having 75,000 MTPA Capacity

Tran Xuan Nam, Mill Director, Xuong Giang Paper, says: “Although we experienced this before when our first ANDRITZ tissue line went into operation, we were still excited to see the first paper on reel from the second line. We are proud to be able to continue and expand our strategy of sustainable high-quality tissue production. Especially the HC refining system and the steel Yankee with the steam-heated hood make a difference in terms of fiber quality and energy efficiency.”

The PrimeLine tissue machine for Xuong Giang Paper is the fifth one supplied by ANDRITZ to the Vietnamese market in recent years and once again proves ANDRITZ’s position as a leading supplier to the Asian tissue industry.