Philip Tapsall

The 21st of March marks International Day of Forests. For businesses, the day comes as a friendly reminder of the importance of forests and how paper companies can play a crucial role in contributing to the conservation of the world’s rapidly depleting forests.

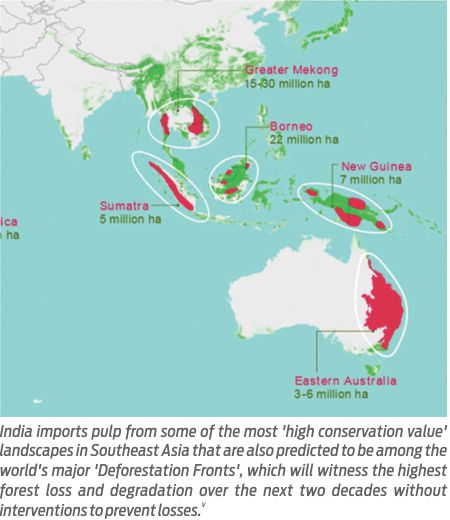

Global demand for paper is on the rise – Asia alone accounts for 45% of the world’s paper and paperboard demand.i According to the FAO Forestry Statistics of 2014, India is the 10th largest consumer of wood pulp for paper in the world, consuming 3% of global volumes.ii India’s imports of wood pulp have been growing steadily over the last 5 years (2011-15) at an annual growth rate of 10% and, as of 2013, nearly all of the imported pulp we use comes from plantations in Southeast Asia. From 2011-2013, Indonesia accounted for the largest share of wood pulp imports to India (close to 30% of total imports).The production of pulpwood from drained peatlands is a production system that causes extremely high carbon emissions and, at times, catastrophic fires that affect local livelihoods and release very large amounts of carbon dioxide into the atmosphere. In fact, the pulp and paper sector was estimated in 2009 to generate more than 600 million tons of carbon dioxide emissions per year, more than 70% of which result from the conversion of peatland for plantations.iii

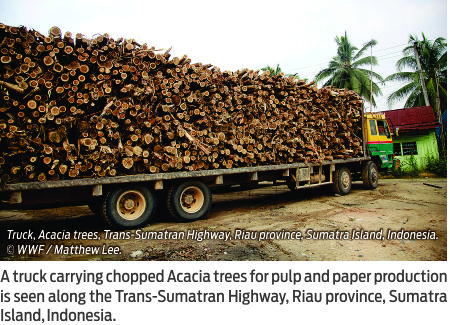

However, these imports come at a larger cost. Since the mid-1990s, forest conversion for pulp and paper production in the tropics has largely occurred in Indonesia, primarily on the island of Sumatra. In fact, the pulp and paper industry is one of the biggest drivers of deforestation in Indonesia, accounting for roughly 20% of deforestation in the 2000s and 50% of peatland conversion. It is estimated that a significant amount of pulp plantations cleared 2 million hectares of natural forests in the district of Riau, accounting for nearly half the Sumatran province’s recent forest loss.iv

However, these imports come at a larger cost. Since the mid-1990s, forest conversion for pulp and paper production in the tropics has largely occurred in Indonesia, primarily on the island of Sumatra. In fact, the pulp and paper industry is one of the biggest drivers of deforestation in Indonesia, accounting for roughly 20% of deforestation in the 2000s and 50% of peatland conversion. It is estimated that a significant amount of pulp plantations cleared 2 million hectares of natural forests in the district of Riau, accounting for nearly half the Sumatran province’s recent forest loss.iv

On the other hand, on domestic grounds, the Indian paper industry has its own challenges – manufacturers face rising demand for a limited resource, increasing competitive pressures, access to markets, new technology, evolving customer preferences, followed by other environmental concerns of pollution and high levels of water and energy consumption.

A strategic sustainability approach aimed at establishing a credible and responsible supply chain is critical for Indian companies to address these challenges while mitigating larger impacts linked to deforestation.

This involves engagement by Indian paper companies with their suppliers to understand and remove deforestation from their sourcing and deploying clear operating procedures, credible third-party verification, and transparent reporting on sustainability parameters.

The Global Context

The Global Context

The 2014 Climate Summit in New York saw 53 of the world’s largest companies like Cargill, PepsiCo, Unilever and General Mills sign the New York Declaration on Forests (NYDF), through which they committed to eliminate deforestation from their supply chains. Hundreds of companies from the Consumer Goods Forum have made the same pledge in recognition of the need for collective effort to address deforestation and its related impacts.

Since the adoption of the NYDF in 2014, the movement to tackle deforestation linked to agricultural commodities like palm oil, timber, pulp and paper, soy and cattle, has developed rapidly, particularly with the private sector. A report titled ‘Tracking corporate commitments to deforestation-free supply chains’, published by Supply Change in 2016, researched 629 companies with exposure to deforestation risk, and found that 66% of these companies have made at least one public commitment to eliminate or reduce deforestation from their supply chains.vi

Globally, several corporate commitments have emerged in the paper sector as well. For example,  Mondi, an international packaging and paper group, has integrated sustainability across its global supply chain, from the responsible management of forests, through the production and marketing of packaging and paper products to the recycling of these products. All of its leased, owned and managed land is FSC (Forest Stewardship Council) certified. Mondi also supports and uses FSC and other standards for wood and fiber purchased. In 2012, a total of 46 percent of wood supplied to Mondi processing plants was from FSC certified sources and another 19 percent from other certified sources, an improvement of 8 percent against 2010.vii

Mondi, an international packaging and paper group, has integrated sustainability across its global supply chain, from the responsible management of forests, through the production and marketing of packaging and paper products to the recycling of these products. All of its leased, owned and managed land is FSC (Forest Stewardship Council) certified. Mondi also supports and uses FSC and other standards for wood and fiber purchased. In 2012, a total of 46 percent of wood supplied to Mondi processing plants was from FSC certified sources and another 19 percent from other certified sources, an improvement of 8 percent against 2010.vii

Moving Forward in India

Moving Forward in India

In the long run, true change will require making a commitment to a credible supply chain. For example, one’s of India’s largest paper and paperboard manufacturers, ITC-PSPD, works towards developing market linkages with responsible suppliers across the globe and ensuring that 100% of the fibre it uses is of known and legal origin. Domestically, the company ensures responsible wood procurement through its farm and social forestry initiatives. All of the company’s domestic wood sourcing areas have been assessed as per the standards of FSC-Controlled Wood and every year an increasing proportion of this area is being covered under the credible FSC-Forest Management certification. ITC-PSPD also looks to promote the uptake of FSC in the Indian market, and the increasing volume of certified fibre being sourced from these plantations enables the company to offer to discerning customers credibly certified products, labelled under FSC’s Chain of Custody (CoC) certification scheme.viii

For Indian papermanufacturers, responsible paper production can start with knowing where their wood pulp comes from, even before setting ambitious goals with measurable targets. This initiative can be backed by a step-wise strategy that involves:

– Tracing where pulp is being procured from.

– Identifying potential ‘unwanted’ sources that are linked to deforestation that should be avoided.

– Building capacity with producers to drive productivity and yield improvements towards sustainable production.

– Continuous improvement to gradually move towards a credible supply chainthat is ‘deforestation-free’ or certified-sustainable procurement.

WWF’s Global Forest & Trade Network (GFTN) is an ideal starting point for companies. Its structured, step-wise approach provides assistance in overcoming challenges to responsible forest management and fibre purchasing by offering technical inputs for better forest management, responsible procurement policies and risk management. Through its global platform GFTN also means better resource mobilization and innovative collaborations with a wider industry network, connecting responsible producers and buyers across the international forestry sector. GFTN hand-holds a company through these steps with the ultimate goal being to attain credible certification across its entire supply-chain.

A more responsible paper industry can support land-holding communities that protect and restore forests, design wildlife-friendly concessions and improve yield and quality for smallholder farmers. Indian companies can benefit from being a part of such an industry, as these measures not only contribute to an important global cause but are also a means to protect brand value, improve supply chain resilience and meet the future requirements of an evolving customer base.

________________________________________________________________________________________________________

Philip Tapsall is Director – Sustainable Business at WWF-India and can be contacted at ptapsall@wwfindia.net

Visit: http://wwf.panda.org/about_our_earth/deforestation/forests_for_life/

______________________________________________________________________________________________________

i. http://www.eulerhermes.com/economic-research/sector-risks/Global-Paper-Report/Pages/default.aspx

ii. FAOSTAT

iii. ITC trade database

iv. http://rainforests.mongabay.com/0807a.htm

v. http://wwf.panda.org/about_our_earth/deforestation/deforestation_front/

vi. Supplychange.org, Progress on NYDF

vii. http://reports2015.mondigroup.com/downloads/sdpublication15.pdf

viii. http://www.itcportal.com/media-centre/press-releases-content.aspx?id=30&type=C&news=ITC