ITC-PSPD has four production units- in Bhadrachalam and Bollaram in Telangana, in Kovai, Tamil Nadu and in Tribeni, West Bengal. The Company is a market leader in both virgin and high-quality recycled fibre-based boards and has the total capacity of 9.2 lac TPA. ITC’s focus on being a carbon-positive, water-positive, zero-solid waste disposal organization leads it to constantly develop ways of reducing, reusing and recycling, and thereby, being an environmentally-responsible and sustainable organization.

ITC’s Paperboards & Specialty Papers Business (PSPD) integrated facility at Bhadrachalam has been conferred the GreenCo Platinum+ rating by Confederation of Indian Industry (CII) Green Business Centre, as part of the Green Company rating system. It is the only facility in the pulp & paper sector and the second company overall in the country to have received this prestigious rating

ITC: A Water Positive Company

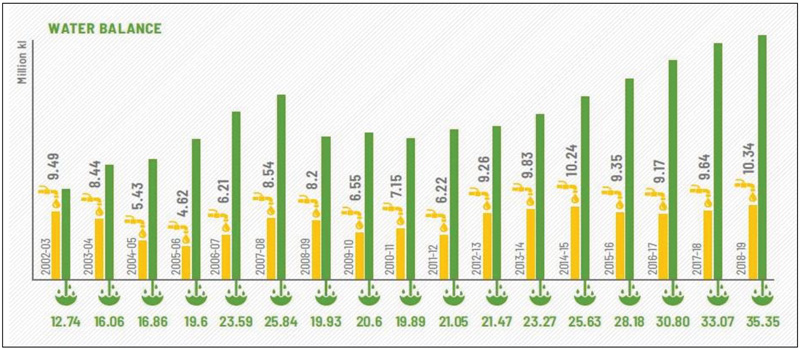

Over the years, ITC has been creating rainwater harvesting capability through extensive investments in its integrated Watershed Development projects. As on March 31, 2020, these projects covering over

1.13 million acres of land have created a total rainwater harvesting potential (RWH) of close

to 39 million kl — over 3 times the net water consumed by ITC’s operations in 2019-20.

Water Scenario: Bhadrachalam Unit

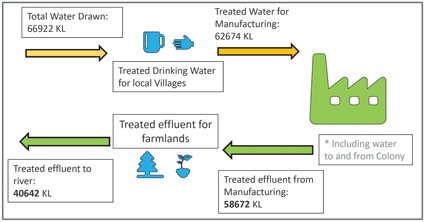

ITC PSPD unit in Bhadrachalam draws water from river Godavari, which is a perennial river. Out of the water intake for consumption, the treated effluent flows back to river. A significant portion of the treated water is released for irrigation purposes, which is an important source of water supply for farmers. ITC also developing biodiversity park in association with Telangana government by using treated effluent water

Although the Godavari is a perennial river, it is reported to be short of water supply for about three months from March to May of the dry-season. Thus, as part of our water management and conservation, we have decided to work extensively on water harvesting structures like check dams, form ponds etc. (beyond the fence or beyond the premises of our production unit), resulting in farmers not dependent on river for their agricultural activities. In addition, we ensure that no ground water is extracted for process.

Although the Godavari is a perennial river, it is reported to be short of water supply for about three months from March to May of the dry-season. Thus, as part of our water management and conservation, we have decided to work extensively on water harvesting structures like check dams, form ponds etc. (beyond the fence or beyond the premises of our production unit), resulting in farmers not dependent on river for their agricultural activities. In addition, we ensure that no ground water is extracted for process.

Approach and Methodology

We have formed a structured approach and methodology to maintain water usage efficiency by ensuring that we reduce water consumption by 5%, maximize reuse in process and increase the recycling of treated effluent. Further, we work towards enhancing the capability of employees so as to equip them with the relevant knowledge, we are always on the lookout to adopt innovative water-efficient technologies, and we give diligent attention to water conservation beyond the boundaries too.

Senior Management Commitment

A strong commitment and initiative towards water sustainability has been demonstrated by ITC’s senior management through various measures:

- Allocating Resources: Providing the required resources in terms of CAPEX, manpower and other infrastructure.

- Setting Goals Setting: Benchmarking and setting the targets.

- Forming Team: Forming and empowering the cross functional team for water conservation activities.

- Progressive Reviews: Periodical reviews and guidance for improvement.

- Celebrations: Rewarding, recognizing and celebrating the achievements.

Employee Involvement and Capacity Building

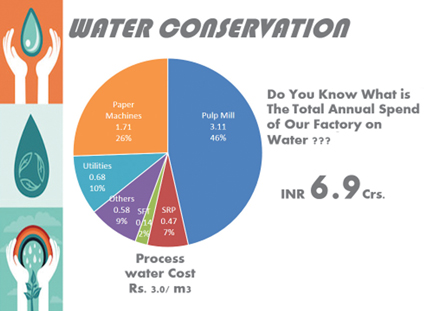

The total annual spend of ITC’s on water conservation is around INR 6.9 crore.

Case Study 1 (Recycle)

Case Study 1 (Recycle)

Power Plant: The steam coming out from turbines are condensed in a tube and shell type surface condenser. The Cooling towers are used to reduce the temperature of outlet hot water which is re-circulated again in the system.

The condensers are provided with online cleaning system to avoid the deposits. Hence, it was tried to use the treated effluent for makeup of cooling tower after passing through filtration and softening plant. We have been able to save 1500 KL/day (Horizontal deployable) through this methodology.

The condensers are provided with online cleaning system to avoid the deposits. Hence, it was tried to use the treated effluent for makeup of cooling tower after passing through filtration and softening plant. We have been able to save 1500 KL/day (Horizontal deployable) through this methodology.

Case Study 2 (Reduce): Paper Machines-Wire Lubricating Showers

A paper machine requires around 2300 CUM water per day for wetting and lubricating the forming wire. This water is sprayed evenly through showers. Now, the water requirement to lubricate evenly the forming wire has been optimized with the latest “Diamond Tip shower nozzles”. The nozzle size was reduced from 1 to 0.7 mm diameter with self-cleaning arrangement without compromising on quality. With this modification, we have been able to lower the consumption of water by 825 kilo liters per day, with horizontal deployment across the units.

Case Study 3 (New Board Machine): Selecting and Adopting Water Efficient Technologies at Design Stage

Case Study 3 (New Board Machine): Selecting and Adopting Water Efficient Technologies at Design Stage

- As water ring vacuum pumps are used on conventional paper machines, it requires huge amount of fresh water. Our project team came across the latest technology of “Turbo air blowers” which has been introduced recently and operates without sealing water. Thus, ITC adopted this technology for our new board machine, although it had a higher capital cost.

- ITC PSPD unit in Bhadrachalam is India’s first BCTMP plant. The state-of-the-art BCTMP plant was designed especially for low water requirement and liquid discharge to ETP. The spent liquor coming out of the process is concentrated in evaporators along with the black liquor of existing ECF pulping. This results in low discharge to ETP and hence lower make-up in the system.

Achievements

In the last two years, we have been able to reduce 4,272 KLD of freshwater consumption, reuse 8400 KLD of back water and recycle about 4,700 KLD of treated effluent from mill ETP for process application.

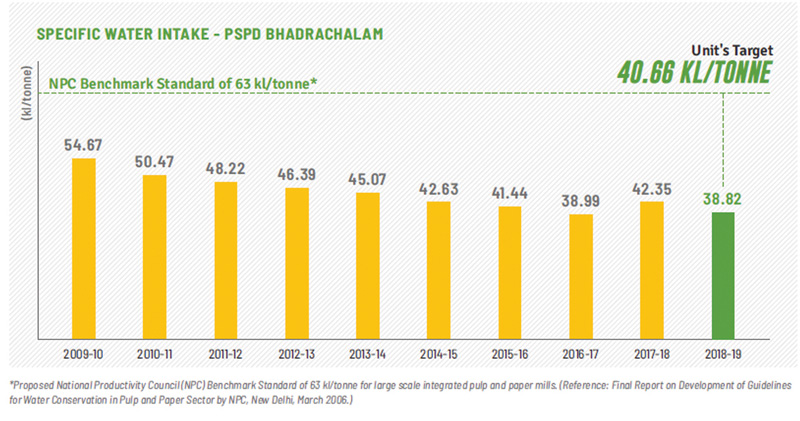

Achievements: Water Usage Efficiency Trends

ITC’s 3-fold Approach to Water Stewardship

We have created a 3-fold approach to water stewardship, which are:

- Integrated watershed development across 16 Indian states covering 1 million acres.

- Enhancing water use efficiency in agriculture through demand side management.

- Maximizing water use efficiency

Within our approach of water conservation, we ensure that we are efficiently using the resource as by making sure that there is a continuous monitoring of water use efficiency, assessment and mitigation of water related risks at local watershed level, and grassroot capacity-building for efficient water usage in agriculture. In addition, we ensure to maintain sustainability of agriculture through integrated water shed development, conduct water security studies and hydro-geological assessments of all operational units, create rain water harvesting potential within and outside company premises and most importantly, we carry out the recycling/reusing of all treated effluents.

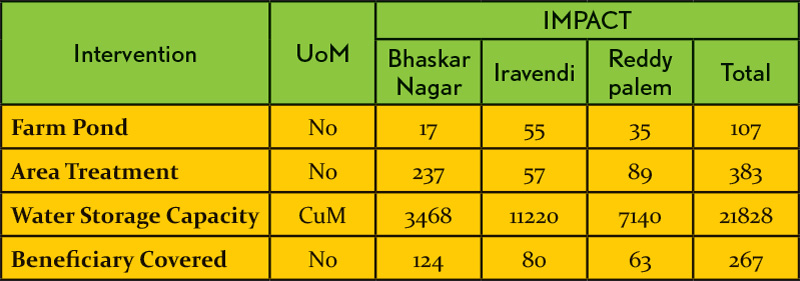

Case Study 1: Beyond the Fence

- Water Harvesting structures developed: 1134

- Bio-diversity plots: 66

- Water Storage Capacity – 4.5 lakh CUM

- Beneficiaries – 16,434

Natural Resource Management in Bhadrachalam Factory Catchment area

Case Study 2: Beyond the Fence – To Educate the Farmers about Water-Efficient Means in Irrigation

Case Study 2: Beyond the Fence – To Educate the Farmers about Water-Efficient Means in Irrigation

Water is a critical input for agricultural production and the agriculture sector accounts for 80% of total water withdrawals and consumption, out of which 60% is consumed by paddy alone. Traditionally, the flooding method of irrigation is used for growing paddy with 2-3 centimeters of water. This practice of irrigation results in large scale water consumption with lower water use efficiency.

There are many methods of paddy cultivation but the SRI (System of Rice Intensification) method totally deviates from the traditional way of cultivating irrigated paddy and hence, it has different water saving capabilities. The method appears to be the most efficient method of paddy cultivation with water savings reaching up to 40- 50% when compared to traditional method of paddy cultivation.

Last year, we have presented 5 demos in the murreru catchment area to mobilize the farmers towards water use efficiency; however, we are planning to scale up these demos to 60. As there is a compelling need to address the water security issue, we want to promote water use efficiency methods and educate the people in the community about various ways to conserve water.

Awards & Certifications

ITC PSPD’s Unit Kovai is first site in India and first Paper Mill in the world to achieve platinum rating, the highest rating under the Alliance for Water Stewardship standards. The company has also received National Award for Excellence in Water Management 2019. It was awarded with Telangana State Energy Conservation Awards 2018 and TSREDCO Energy Conservation Award – 2019. ITC PSPD Bhadrachalam unit was conferred with IPMA Environment Award 2017-18 and CII -National Water Conservation Award – 2019

Challenges and ITC’s Action Plans

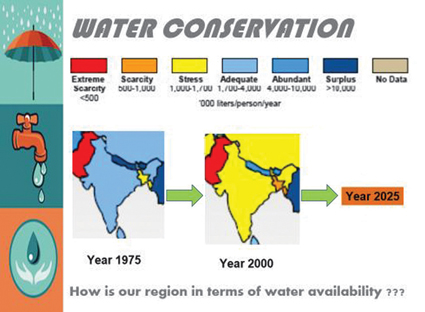

Within Fence: There are some pertinent challenges with regard to water usage that we have to consider – there has been a continuous decline of ground water and drying of rivers which thus results in the regulatory limits on water withdrawal for businesses and the deteriorating water quality entails additional treatment expenses.

To address these challenges, ITC’s Action Plans are to – continuous monitor water use efficiency, focus on Reduce – Reuse – Recycle methodology, and continued investment on rain water harvesting potential. Also, we plan to conduct water security studies and hydrological assessments for operating units located in high water stressed areas.

Beyond fence: The key challenge in the area of water conservation beyond our fence/premises is, as water is a crucial input for agricultural supply chain as well as production, business operations may get affected due to potential disruption in water availability.

Thus, ITC’s Action Plans to solve this challenge is by ensuring sustainability of agriculture through water shed development, soil and moisture conservation projects, aquifer recharge particularly in areas where ITC sources its raw materials. Moreover, we also give attention to engagement with external stake holders for assessment and mitigation of water related risks at local watershed level.

Paper Industry Specific Challenges

There are some major limitations for recycling/re-use of back waters in Indian mills:

-Increased operation problems due to change in water quality: Accumulation of various organic and inorganic components.

-Corrosion problems: Increased levels of calcium, chlorides, sulphates and suspended matter.

-Adverse impact on the product quality: Lower retention and drainage of the additives.

-Increased levels of microbial population (slime): Rise in temperature by water recycling- affecting the runnability of paper machines.

Some of the other challenges are — Recycling of treated effluent within the process is limited by the TDS limit of effluent discharge (2100 mg/l). The technology on TDS reduction is still commercially not viable and the business can be at risk due to no alternate source of water (Use of ground water is not allowed for industries). There are restrictions on water drawl during summer have impacted production in some units. In spite of these challenges, there are opportunities that we can rely on – Opportunity for cross industry learnings of best practices, treated effluent use for agriculture, as it has high nutrients. Moreover, the support from industry experts like Valmet and Andritz has helped us with reliable and efficient water audits. There is a huge opportunity beyond the fence, check dams, ponds, rain water harvesting etc. ITC-PSPD also believes in continuous improvement with employee involvement through innovative ideas and kaizens generation for improving water-use efficiency.