PGA Anlagenbau GmbH is a leading supplier of starch and coating kitchens, additive plants and chemical plants. Since 20214, the company based in Wernberg (Austria) is part of the IBS Paper Performance Group. With a long experience in special dispersing machines of coating kitchens, PGA developed the iFIBRE concept.

Mr. Christopher Krainer, Product Manager of iFIBRE systems, shares an insight into this patented system for the treatment of fibre suspensions.

What is the iFIBRE?

The iFIBRE is a high shear mixer which operates continuously with consistencies between 2-6%. The system creates a high-frequency of intense fibre to fibre friction without shortening the fibres and generating fine material.

Where in the paper mill iFIBRE can be installed?

In general, an iFIBRE system can be installed in all paper mills using any type of furnish. However, the application of the iFIBRE depends on what that particular mill wants to achieve. The iFIBRE family is divided in three applications:

iFIBRE deSAVER:

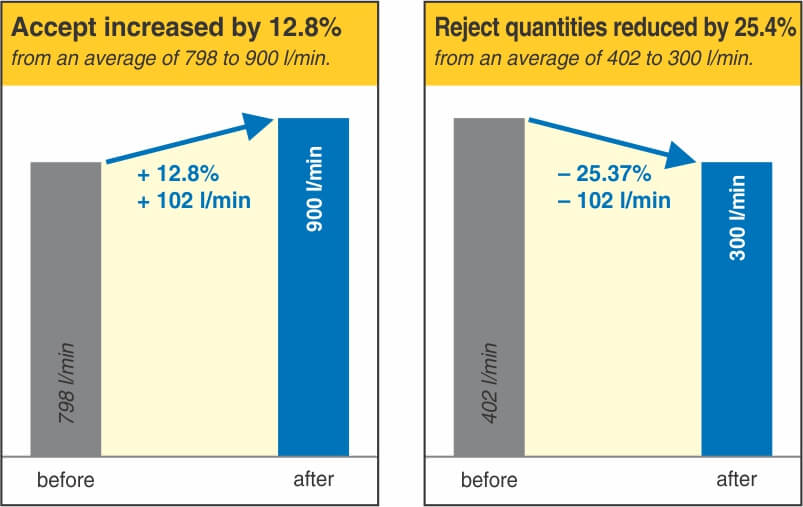

The target of the iFIBRE deSAVER is to reduce reject in the screening process. The system is especially designed to improve the efficiency of existing screening plants in waste paper-based mills. Its area of application is in the reject line of stage 1 or 2 in the fine screening. Alternate areas of application are in the coarse screening or fractionation. The deSAVER significantly reduces reject quantities and thus saving fibre. Moreover, reduction in reject also mean saving in dumping costs.

iFIBRE deTUNER

The iFIBRE deTUNER saves energy and optimizes refiner lines. The solution is especially designed for the optimization of refiner lines (connected in series). When treating fibre suspensions with the deTUNER, stock freeness (Degree SR) is slightly increased without shortening the fibre. This increase is often sufficient to switch-off one of the refiners connected in series. Since the deTUNER is very energy-efficient and requires little maintenance compared to a conventional refiner, it pays back the investment in a noticeably short period of time.

iFIBRE deFLAKER

The iFIBRE deFLAKER homogenizes stock suspensions — Due to the high shear forces achieved by the special design of the system, fibre suspensions are dispersed and homogenized using minimal energy. It is resistant to impurities such as stones, wires, etc. The most common applications of the deFLAKER are directly after the pulper or after the mixing vat. The application of a deFLAKER after the dissolving ensures an optimal preparation of the stock suspension for the subsequent refining process.

How does iFIBREsystems work?

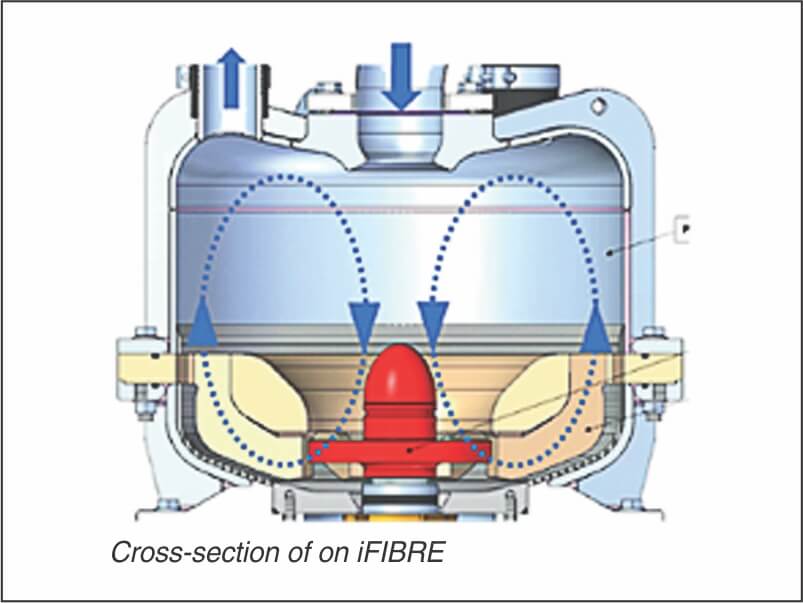

The basic functionality of iFIBRE systems is similar. The pulp suspension entering the iFIBRE at the top is led to the rotor and is thrown against the stator with rotational acceleration. Due to the circulation and the different speeds within the iFIBRE, the fibre bundles within the suspension are opened, resulting in a highly homogeneous stock suspension. The cautious treatment of the suspension does not destroy the fibres. Further on, impurities are not crushed and can be exit from the process reliably. deSAVER, deTUNER and deFLAKER differ in their distinctive and special design of internals, rotor, stator and control parameters such as dwell time, frequency, flow rates.

In which sizes iFIBRE machines are available?

We have a big range from 10m³/hour to 350m³/hour.

Please tell us about other activities of PGA?

As mentioned before, PGA is well known for starch kitchens, coating kitchens, additive plants and chemical plants. The company started its operations in India during 2017-2018 through its representative Omicron Paptech LLP which has its head office in Mumbai. Since its cooperation with Omicron, PGA has sold 2 fully automatic enzymatic starch kitchen lines in India; one plant to a mill producing liner kraft and another to a writing & printing paper mill.