For over 150 years, Billerud has been a leader in paper and packaging materials. They share a deep respect for the forest and are passionate about creating sustainable solutions. The world needs packaging, but it should come at minimum expense of the environment. That’s why responsibly sourced raw materials are used to produce high-performance packaging materials that are renewable, recyclable, and reusable. At Billerud, they believe every aspect of packaging can be improved and that more sustainable solutions are essential tools for shaping a better tomorrow.

Sustainable Forestry

Our work begins in the forest. Forests sustain vital ecosystems and support climate regulation, benefiting both society and the environment. Through retention forestry, younger, faster-growing trees can flourish, ensuring a sustainable supply while enhancing CO ₂ storage capacity within the forest. All our wood is traceable and controlled, and we strive to increase the share of certified wood for responsible management and reforestation. We partner with small forest owners, educating and empowering them in sustainable management practices. By working together, we can ensure responsibility and sustainability to create a positive environmental impact for generations to come.

Younger trees grow more and faster than older ones and therefore bind more carbon dioxide into the biomass. The forest produces renewable climate-smart raw materials that can replace fossil and finite raw materials. Active forestry is therefore climate efficient and good for a sustainable future.

Around three quarters of the wood raw material used by our Swedish industries comes from Swedish forests and all wood into our US mills originates from the USA and Canada. Billerud has procedures and guidelines to avoid wood being purchased from illegal felling operations, from forests with high preservation values, from regions with serious social conflicts and where felling leads to deforestation.

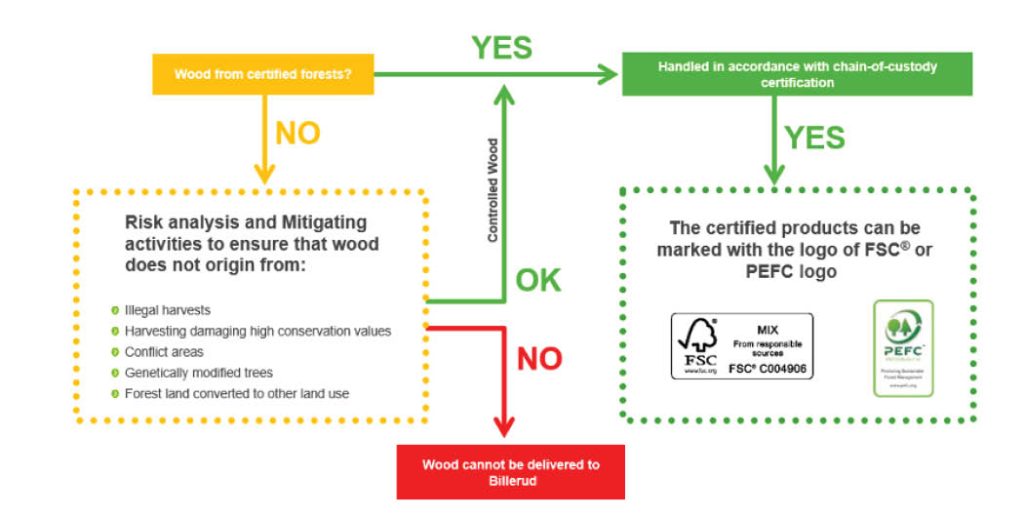

National laws and regulations for forestry are a minimum standard for Billerud. We are third-party certified to chain of custody standards set by the Forest Stewardship Council® (FSC®), Programme for the Endorsement of Forest Certification (PEFC), and in North America, the Sustainable Forestry Initiative® (SFI®).

Billerud’s due diligence system ensures that all purchases follow the procedures set out by FSC® Controlled Wood, Controlled Sources in PEFC Chain of Custody and comply with the EUTR and US Lacey Act timber legislations.

Sustainable Technology

At Billerud, we’re committed to minimizing our environmental footprint through innovative technologies. We produce 98% of our process energy from renewable biomass, reducing our reliance on fossil fuels. We also use the excess heat to warm thousands of surrounding homes and a 100,000 square meter greenhouse where tomatoes grow. Our water treatment plant also ensures negligible impact on nature. We specialize in developing high performance products that are entirely recyclable, making our European packaging material portfolio the first to be third-party assessed as 100% recyclable.

Resource Efficient Production

Stable production and using resources effectively are two of the most important factors in minimizing emissions to air and water from our mills. At the same time, we are working to phase out fossil fuels, increase our energy efficiency, and minimize our water usage and impact on water quality.

Watch: In Pursuit of Lesser Water Footprint

Energy Efficiency

We have already come a long way with phasing out fossil fuels in production. Our efforts to minimize the negative environmental impact are based on systematic work for constant improvements and investments in new technologies, with the goal to run efficient operations with consideration for the surrounding environment and the local community. We have reached a 98% fossil-free production in Region Europe and are working to minimize the usage of fossil fuel in Region North America, which currently is 55% fossil-free.

Billerud’s production is energy intensive. Most of the energy consumed is generated in the pulp process, where large amounts of waste heat are released. This excess heat is mainly used directly in production, but also provides local communities with district heating. In Europe, all electricity that is produced internally or purchased is covered by Guarantees of Origin (GoOs), and in the US we purchased Emission-Free Energy Certificates (EFECs) corresponding to 60% of the total purchased volume in 2023.

We work continuously to increase the overall energy efficiency of our facilities and to find new ways to further increase the amount of energy produced from renewable resources.

Water Management

We are committed to minimizing the impact of our water use and our impact on water quality. Surface water is mainly withdrawn for our production processes and returned to waterways. There is no significant water consumption in the pulp and paper manufacturing process. Water is reused several times throughout the process before going back to the effluent.

Reuse and Waste Recovery

Billerud strives to use raw materials in the most efficient way possible. For example, most of our energy comes from the fiber residues in our manufacturing process, whereby the cellulose fibers in the digester process are extracted using cooking liquor containing inactive chemicals as well as fiber residues. When incinerating the concentrated cooking liquor in the recovery boiler we recover and reuse the chemicals as well. In the production process, the significant material flow of waste and waste recovery can be described as follows:

- Bark from wood logs is used in solid biofuel boilers for energy production.

- In the recovery process the cooking chemicals are recycled and energy is recovered from wood residues.

- Turpentine is a by-product from the pulping process, and we supply it to other industries.

- Soap is another by-product that can be traded to an external manufacturer or processed into crude tall oil within the mills. Crude tall oil can be used as an energy source internally or traded to biorefineries that, for example, produce renewable fuels and biobased chemicals.

- Paper and paperboard material waste is dissolved and returned to the production process. The paper and paperboard production also provides residues from coating chemicals that can be used as cover material for landfills after external processing.

- Fiber and bio sludges are separated from the wastewater and are either incinerated for energy recovery or used for soil improvement.

Carbon Capture and Storage

Regardless of where the carbon dioxide emissions originate, we will do our very best to reduce them. We aim to develop solutions that reduce biogenic carbon dioxide emissions in addition to fossil carbon dioxide emissions. One promising technology is Bioenergy Carbon Capture and Storage (Bio-CCS).

We are investigating the possibilities within the field of Bio-CCS and we hope to contribute to increased knowledge in general and our own expertise. Billerud has one ongoing project that involves using the residues that arise in our process to capture carbon dioxide from flue gas from the chimneys. After the capture of carbon, the storage possibilities for now are offshore. This project investigates the possibility to store the captured carbon in the rock. A suitable type of bed rock has been discovered directly beneath the site of Karlsborg mill. The same geographical circumstances occur at several pulp and paper sites in Sweden, so if this is a possible technical solution it would really make a difference. Another alternative is to work with Bioenergy Carbon Capture and Usage. In this case the carbon dioxide is mixed with hydrogen and can be used as a replacement for fossil fuels or as feed stock in the chemical industry.

Also Read: Södra Signs Agreement with UPM and Stora Enso to Supply Kraft Lignin by 2027

Responsible Supply Chain- Sustainable Logistics

Billerud procures raw materials, wood, chemicals, transport, products, energy, and services from its global supplier base. Working towards a sustainable supply chain means that all purchasing decisions must be made in line with principles of business ethics and comply with the sustainability criteria.

Our efficient and reliable logistics can play a crucial role in reducing your Scope 3 emissions. We prioritize on-time delivery while utilizing trains for 70% of outbound transportation from our European facilities, with ambitions to further increase this figure. Co-locating our pulp and paper packaging production facilities adds another efficiency advantage, optimizing logistics and minimizing transportation.

Sustainable Advisory for Wiser Decisions

We collaborate closely with brand owners and converters, leveraging decades of know-how in sustainable packaging. Our high-performance materials enable lightweighting, reducing both costs and carbon footprint. With services like packaging optimization and performance testing, we ensure your packaging meets high standards of efficiency and environmental responsibility. We proactively guide the transition to a circular economy, helping you achieve the perfect balance between efficiency and sustainability.

Supplier Evaluations

We have a continuous dialogue with our suppliers to increase their knowledge of the content of our Supplier Code of Conduct, and to strengthen their performance within sustainability and ability to meet our requirements. We continuously encourage our suppliers to develop and improve sustainability in their end-to-end supply chains. We have routines in place to identify suppliers that are critical to the business, such as suppliers of direct materials, suppliers with a purchase value over or certain threshold, or who are deemed to have a sustainability risk. Risks are considered when onboarding new suppliers and are monitored during ongoing business. This includes environmental risks as well as screening against Billerud’s list of excluded and high-risk markets (defined as jurisdictions perceived as having high risk related to responsible business, e.g. human rights, labour rights and/or and corruption.)

Billerud implemented a collaboration with EcoVadis, a third-part solution for supplier assessments, during 2019. EcoVadis provides an evaluation that is based on the supplier’s size, industry, and location. The evaluation consists of four main categories- environment, labor and human rights, ethics and sustainable procurement.

After being evaluated by EcoVadis, suppliers receive a rating and a scorecard. Billerud has set rating levels for approval, approval with conditions or non-approval. Suppliers that are approved with conditions shall commit to improve their performance and carry out improvement activities. In these cases, the supplier needs to implement a Corrective Action Plan (CAP). When deviations are identified, we provide guidance and support to help the supplier to implement systematic improvements. Suppliers that are not approved may pose a risk to Billerud, and in those cases, Billerud has the right to terminate contracts with the supplier and will not source from that supplier. A high evaluation score is an advantage in supplier selections.