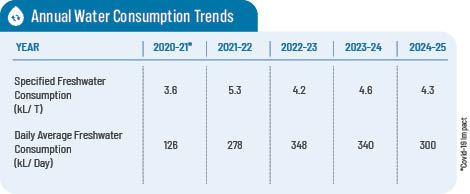

Chandpur Paper’s approach to water circularity has evolved from merely reducing freshwater consumption to actively reusing treated effluents, aiming to establish a closed-loop system. The company has adopted advanced technologies, including upgraded showering systems and kidney technologies like microscreen filters to maximize wastewater usage, thereby reducing freshwater consumption and enhancing internal recycling. In an exclusive interview with Paper Mart, Mr. Devesh K. Singhal, Director and CEO (Technical), reveals how the company has successfully lowered its freshwater consumption from 348 kL per day in 2022–23 to 300 kL per day in 2024–25. He emphasized Chandpur Paper’s commitment to comply with regulatory requirements by integrating efficient systems that align with their long-term sustainability goal of minimal freshwater intake and maximum utilization of treated water.

Paper Mart: How has your understanding or approach to water circularity evolved over time? How close are you to achieving it?

Devesh K. Singhal: Our approach to water circularity has evolved from simply reducing consumption to actively reusing treated effluents. Initially, our focus was on conservation, but over time, we have integrated systems to recycle backwater and primary treated wastewater, significantly cutting down freshwater usage. Our goal is a closed-loop system that maximizes every drop, aligning sustainability with operational efficiency.

PM: To what extent have you implemented internal water reuse, recovery, or circularsystems (including ZLD, water loop closure, or rainwater harvesting)?

DKS: As we are manufacturing quality poster paper grades, reduction in water consumption is possible to an extent only. Too much closure starts affecting paper quality such as its shade, water resistance, and other features adversely. As per CGWA guidelines, in order to prevent pollution of groundwater due to recharge, all red category industries (industries that have a pollution index score of 60 and above), cannot recharge within the premises.

Watch: In Pursuit of Lesser Water Footprint

PM: Which technologies or solutions have you found most effective in reducing your freshwater consumption or increasing internal recycling?

DKS: We’ve adopted technologies like improved showering systems, microscreen filters, and kidney solutions such as Megacell to reduce freshwater use and enhance internal recycling. These innovations have optimized water usage across operations, significantly lowering our dependence on freshwater while promoting sustainability through efficient reuse and minimal discharge.

PM: What are the biggest roadblocks (technical, financial, or regulatory) in achieving higher levels of water reuse or moving toward ZLD?

DKS: For waste paper-based mills, we need to understand that the waste paper is nothing but paper that has undergone treatment like glueing, printing with inks, coating with barriers and other chemicals, etc.

Today, different types of chemicals are available in the market, and these make the effluent system so complex that no treatment system can guarantee 100% treatment. The problem gets intensified with the reduction in freshwater consumption. As a result, both the capital expenditure (CapEx) and operational expenses (OpEx) for the effluent treatment plant have substantially increased, which is a great challenge for the paper industry.

PM: How do local or national regulations affect your water management goals? Have sustainability mandates accelerated your water-saving initiatives?

DKS: We operate well within the local and national water regulations, which reinforces that our water management goals are already being met. While sustainability mandates haven’t directly accelerated our initiatives, they validate our proactive efforts. We’ve consistently aimed beyond compliance, integrating efficient systems that align with both regulatory expectations and our long-term sustainability vision.

PM: Have your investments in water reuse or ZLD technologies paid off in terms of savings, efficiency, or compliance?

DKS: Our investments in water reuse have paid off by ensuring full compliance with regulatory norms. Compliance itself translates to significant savings—avoiding penalties, reducing freshwater dependency, and improving operational efficiency. These investments have strengthened our sustainability credentials while delivering long-term value across environmental and economic parameters.

PM: Do you involve technology providers in planning or customizing your water treatment systems? Any successful collaborations worth sharing?

DKS: We encountered an interesting case where a significant reduction in water consumption led to operational issues on one of our paper machines. After a thorough review and discussion with the supplier, we installed a specially designed set of showers for that particular paper machine. The new system effectively eliminated the problem. As a result, we have placed an order for a similar showering system for the other machine.

Also Read: Haber: Sustainability Begins With Smart Water Audits

PM: How do you see your water use evolving in the next 5–10 years? What would “full circularity” look like in your operations? What kinds of support in terms of technology, partnerships, or policies would help you get there?

DKS: With the increasingly changing market conditions, developing technologies, and dynamic policies, the next 5–10 years can be difficult to predict. Yet our dedication to constant improvement is unwavering. For us, complete circularity implies minimum freshwater intake and maximum utilization of treated water. To achieve this would need to be supported by innovative technologies, robust policy incentives, and collaborative partnerships to scale up sustainable solutions effectively.

PM: Have you considered or implemented digital twins to simulate, monitor, or optimize your water use? What kind of improvements could such systems bring to your operations?

DKS: We are implementing a plant-scale data visualization project for one of our paper machines, which will function similarly to a digital twin. This system will enable our teams to monitor real-time operations, including water consumption, and identify optimization opportunities. Such digital tools enhance visibility, improve decision-making, and can lead to more efficient water use, reduced waste, and better alignment with our sustainability goals.

We are implementing a plant-scale data visualization project for one of our paper machines, which will function similarly to a digital twin.