Digital sheet break solution provides a root cause analysis within one minute and acts as early warning system in a way not possible with current manual solutions.

April 14, 2021

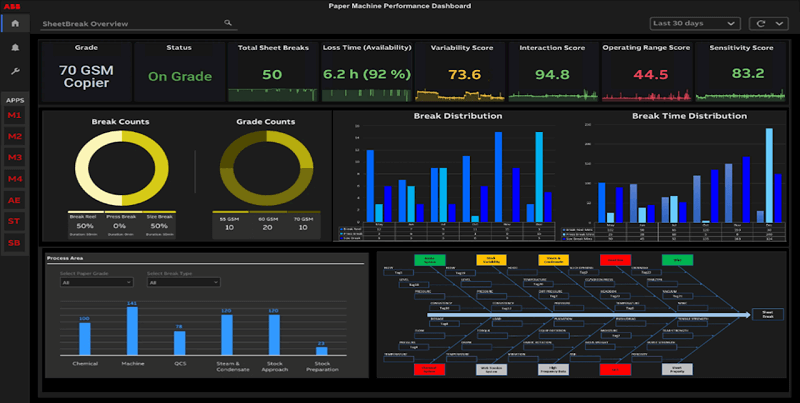

ABB has released Sheet Break Performance, an ABB Ability™ Performance Service that automatically curates, calculates and contextualizes key data points into an intuitive user interface to reduce the time to identify the root cause of sheet breaks for swift corrective action, while also determining optimal operational parameters to help prevent unplanned downtime.

The digital service quickly pinpoints the underlying issues and recurring trends that prohibit optimum performance in paper mills and specifically addresses pain points such as frequent sheet breaks, long recovery times and increases in paper rejects.

Watch: Adler Paper: Turning Waste into Meaningful Resources.

The diagnosis and root cause identification of each sheet break event is traditionally performed manually by operators who often need to access the information from different sources, such as process control systems, drives and quality management systems. This requires the breakdown of data from multiple systems and interactions between process variables, which is time consuming.

ABB’s digital offering, which is built on a powerful combination of a proprietary analytics engine, advanced algorithms and online monitoring, provides a root cause analysis within one minute after the break.

With the ability to monitor the real time variations in the operating parameters as well as the interactions between the various sections of the paper machine, operators are alerted to abnormalities and detrimental changes in the system that could lead to sheet breaks. This serves as an early warning system allowing the operators to take corrective actions and prevent unplanned downtime.

This switch from manual to digital analysis can prove to be a useful stepping stone in a mill’s transformation and can also help to make a mill more sustainable by lowering energy usage, raw material and water footprint while improving fiber recovery. Plus, it reduces safety concerns with operators less frequently having to enter the dryer to extract broken paper.

Also Read: ANDRITZ Signs Industrial Maintenance Contract with LD Celulose S.A. in Brazil.

Delivered via the ABB Ability™ Collaborative Operations service delivery model, it is fully integrated with ABB Ability™ Analytics framework, with on-premise or cloud deployment options.