Andhra Paper Limited (APL) has earned quite a reputation for manufacturing its products responsibly and actively working to reduce its environmental impact by promoting sustainable operations. As APL completes seven decades of its existence, it looks forward to exploring new avenues of growth and broadening the path for sustainable development through conscious efforts that not only make a positive difference in the lives of people associated with it, but improve the health of the planet as well.

Sustainable Sourcing of Raw Material

Andhra Paper is committed to delivering high-quality paper products through sustainable and innovative practices. To mitigate risks associated with sourcing wood and fiber for pulp & paper production, APL has implemented a comprehensive ‘Farm Forestry’ program. It partners with farmers within a 150 km radius of its mills to grow trees specifically for paper production, providing them with free saplings and advising them on best practices to promote sustainable agricultural practices. The company has so far planted around 2.062 billion saplings and seeds in around 690,442 acres of land. We have distributed 1,30,49,150 clones and 7,75,84,000 seedlings in FY 2023-34, contributing to carbon sequestration and ensuring sustainable wood sourcing. In order to be environmentally friendly, we have eliminated the traditional practices of poly bag nursery techniques and introduced other low-cost planting techniques.

The initiative has helped the company to become ‘wood positive’ and offered around 86,000 rural farmers an additional source of income. It has further aimed to reduce reliance on external sources by fostering sustainable forestry practices and increasing the availability of raw materials from self-managed forests. APL’s farm forestry program has transformed the ‘wastelands’ of yore into a means of employment and asset creation for the farmers. The perception of paper mills as destroyers of natural resources has been struck down. Instead, they are leading development efforts with the goal of improving forest and ecological systems. The productivity of degraded lands has improved tremendously since the inception of the program, and soil erosion has been controlled. There has also been an observable improvement in moisture conservation. Additionally, the company actively monitors and adapts to changing climate conditions to mitigate productivity risks in forestlands.

Going Green With Eco-Friendly Technologies

By integrating cutting-edge technologies and adhering to stringent environmental standards, we strive to minimise our ecological footprint and secure a better future for generations to come. Andhra Paper is actively mitigating greenhouse gas emissions through a multifaceted approach. This includes substituting fossil fuels with various biofuels in coal-fired boilers, exclusively operating the recovery boiler on 100 percent biofuel derived from black liquor, and maximizing internal power generation efficiency, with 65-68 percent of power needs met by the recovery boiler. We have implemented another innovative project at our Rajahmundry mill that captures carbon dioxide gas & lime mud from limekiln and transforms it into precipitated calcium carbonate (PCC), a material reused as a filler in the paper-making process. The green initiative leads to reduced CO2 emissions and less generation of solid waste. At our Kadiyam unit, recycled paper is reused to manufacture high-quality printing and writing paper, minimizing reliance on virgin material.

Watch: In Pursuit of Lesser Water Footprint

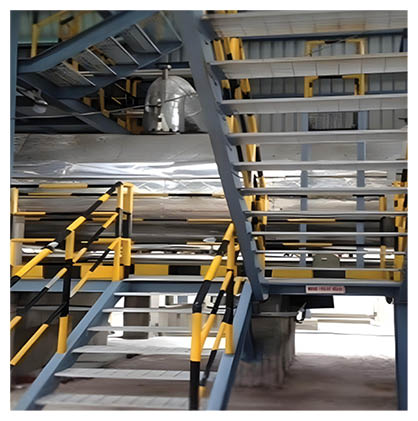

PCC Plant – 125 MTPD – Reduction in Carbon Emission

APL has taken a proactive approach to reduce air emissions through infrastructure upgrades. By expanding the recovery boiler ESP to four fields and replacing 90 electrode plates in the coal-fired boiler’s electrostatic precipitators, dust collection efficiency has significantly improved. The installation of an extra ambient air monitoring station has enhanced monitoring capabilities, demonstrating the company’s commitment to environmental stewardship and regulatory compliance. To mitigate the risks associated with energy-intensive operations, APL has diversified its energy sources by investing in additional renewable sources like solar or wind power, reducing reliance on any single method of electricity generation and increasing resilience to potential supply chain disruptions and regulatory risks.

Continuous investment in energy efficiency measures within the cogeneration plant has optimized energy usage and minimized environmental impact. One of the recent investments includes the installation of a new energy-efficient vacuum pulp pump at our Rajahmundry unit, leading to energy savings of 123.6 KW/hr.

Every Water Drop Counts

APL has implemented a range of water conservation initiatives to address the high water usage inherent in pulp and paper manufacturing, such as reusing backwater and secondary condensate in paper machines, as well as using treated water for gardening. We also repurpose reject from the water treatment plant, upgrade paper machine showers, and reuse white water within machines. We have further optimized cooling systems for RLK bearings and transitioned from fresh to hot water in showers. These efforts have led to a significant reduction in specific water consumption per ton of product, from 68 m3 to 53.5 m3, demonstrating our commitment to sustainable water management.

Putting Waste to Meaningful Use

Andhra Paper is dedicated to minimizing its environmental impact through waste management initiatives. At our Kadiyam unit, recycled paper is reused to manufacture high-quality printing and writing paper, minimizing reliance on virgin material. A dedicated sewage treatment plant in Kadiyam ensures responsible handling of wastewater generated from our facilities. We strictly adhere to regulations for electronic waste (E-waste) disposal and partner with authorised recyclers to ensure proper disposal. Plastic waste is also repurposed as fuel for the cement industry, while organic and inorganic sludge from our wastewater treatment plant is used for the production of egg trays. Fly ash from our operations is utilised in brick manufacturing and paper waste generated during manufacturing is reintegrated into our pulping process. We have significantly reduced our reliance on fossil fuel by substituting it with biofuel in our coal-fired boilers. Biofuel includes renewable sources like black liquor, wood waste and sludge. Our Rajahmundry unit utilises biofuel to generate steam and power for almost 65 percent of its needs. APL has established Standard Operating Procedures (SOPs) for the management of hazardous & non-hazardous wastes, e-Waste, batteries waste, and bio-medical waste, ensuring consistent implementation and compliance across various sections.

Recycling of Plastic Waste

Andhra Paper Limited has registered with the Central Pollution Control Board (CPCB) for extended producer responsibility (EPR) under plastic waste rules (PWR) in 2016. Around 900 tonnes of plastic packages were collected from the market and recycled against EPR target of 900 tonnes for 2023-24 for all locations of Andhra Paper. Certificates of recycling for this amount were issued by a third-party organization approved and registered by the CPCB under EPR.

E-waste

APL is compliant with the authorization order of the State Pollution Control Board for E-waste disposal. The Company sends its E-waste to authorised dismantlers, recyclers and re-processors for proper disposal.

Hazardous Waste

Andhra Paper is authorized by the SPCB to reuse a part of their hazardous waste as a biofuel in their boilers, while the remaining hazardous waste is sent to external parties for recycling or disposal in accordance with the SPCB authorisation order.

Also Read: Kuantum Papers: Setting Strong Foundation for Long-Term Sustainability

Non-Hazardous Waste

The Company complies with the SPCB authorization order for non-hazardous waste disposal. A portion of the non-hazardous waste is sent to authorised external parties for beneficial usage, recycling or disposal, while another portion is reused internally in boilers as a biofuel in accordance with the SPCB authorisation.

Despite operating in a resource intensive sector such as the paper manufacturing industry, APL has managed to fulfil its commitment to ensure environmental stewardship. The company’s vision is to become the top performing and most respected paper company in India by integrating Environmental, Social and Governance (ESG) principles into its growth strategy, which is central to improving the quality of life of the communities it serves. Our robust business model, adoption of emerging technology and automation, brand strength, and customer-centric approach back our robust economic performance.