This is the fourth HERB recovery boiler ANDRITZ is currently installing in India, demonstrating it’s strong presence in the Indian pulp and paper market.

January 10, 2022

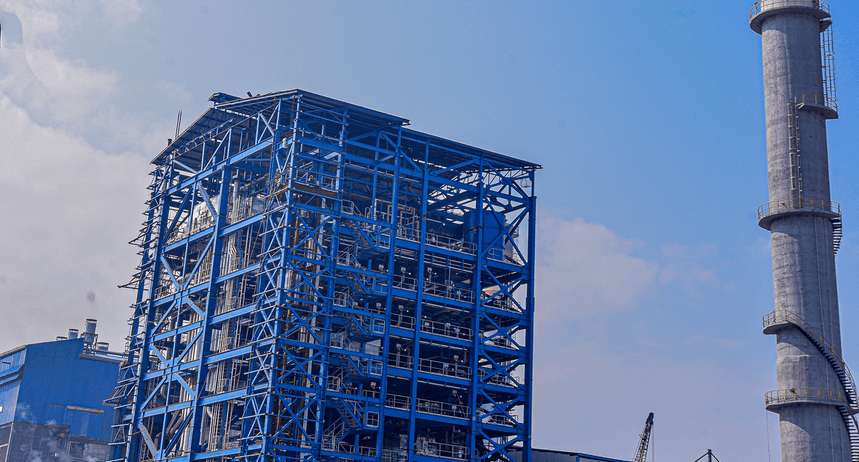

ANDRITZ has successfully started up a new 950 t/d HERB chemical recovery boiler at JK Paper Limited, Unit: CPM at Fort Songadh, in the Tapi District of Gujarat state, India.

The boiler is designed to process hardwood black liquor and enables environment-friendly and more energy-efficient operation compared to the direct-contact evaporator boiler currently used at the mill. This will significantly increase the mill’s pulp production and power-to-heat ratio. The boiler also features a unique air system to minimize air emissions.

The scope of supply also included:

- Engineering for the entire system except for the civil works and the electrical and automation equipment

- Complete pressure parts

- Auxiliaries such as start-up oil burners, black liquor burners, smelt spouts and high-pressure steam valves and piping

- Safety-related system (SRS)

Also Read: JK Paper Joins Hands With IIT Delhi to Set up Centre of Excellence in Paper and Packaging.

Mr. A S Mehta, President & Director of JK Paper Ltd, says: “The entire ANDRITZ team has worked tirelessly and zealously to see that the commissioning was trouble-free and fast. This has been achieved despite many constraints during the COVID-19 pandemic. Team JK Paper conveys its warmest gratitude to the ANDRITZ team for this wonderful support.”