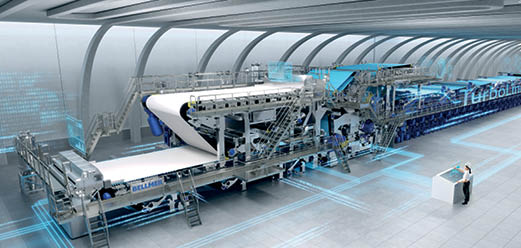

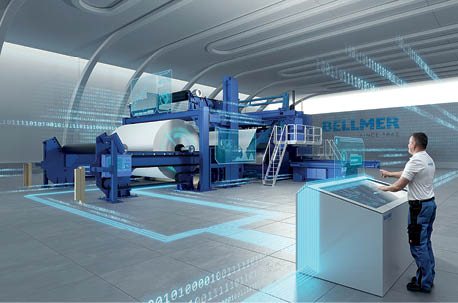

Digital twinning, or the creation of a virtual digital replica of paper machine operations, is poised to transform the pulp and paper industry by enabling the use of artificial intelligence and machine learning in real time. This can significantly minimize wastage, lower costs per ton, and enhance product reliability. In an exclusive interview with Paper Mart, Mr. Ranajoy Chowdhury, Managing Director, Bellmer India explains how Bellmer, as an original equipment manufacturer (OEM), is driving digital transformation by consistently integrating advanced sensors, IoT-enabled systems, and ERP connectivity into its machinery and solutions. He says, while the European mills have developed a robust digital ecosystem, in India the adoption of comprehensive, end-to-end digital twins across entire mill operations is still in its early stages and is expected to take a couple of years to fully implement it.

Paper Mart: What role is digital twin technology expected to play in pulp & paper industry operations today?

Ranajoy Chowdhury: Digital twin technology is one option to significantly restructure paper industry operations by facilitating data driven, fast and efficient decision making. Simulation of a digital replica of paper machine operations could empower the industry to harness the power of artificial intelligence and machine learning in real time. Important is to take on the challenge to get better use of data even in our “physical” production world.

With real-time insights, advanced simulations, and AI-driven recommendations, paper mills can look to minimise waste, reduce costs per ton and enhance product consistency. This is not merely a digital transformation, it offers a substantial competitive advantage in the industry.

Watch: In Pursuit of Lesser Water Footprint

PM: How do you view the potential or readiness for digital twin applications in international paper mills?

RC: European mills have developed a robust digital ecosystem that encompasses everything from the supply chain systems to the finishing lines. Transitioning to digital twin technology for these mills would require minimal capital investment.

European mills are already facing significant pressure to reduce costs, reduce carbon emissions, minimize waste, and decrease downtime. These factors directly affect their profitability and competitiveness against increasing competitions from Asia. Therefore, it would be prudent for these mills to embrace the available technology and leverage it to enhance their efficiency and sustainability process.

To remain competitive, mills must embrace digital transformation and actively leverage them to drive operational efficiency, reduce waste, and meet sustainability goals.

PM: What are the key benefits of implementing digital twins in terms of sustainability, cost reduction, and process optimization?

RC: Adopting digital technology can significantly optimize carbon emissions, energy consumption per ton by simulating real-time operations of boiler loads, drying sections, water and steam usage etc.

These innovative approaches not only enhance sustainability initiatives but also strengthen commitments to Environmental, Social, and Governance (ESG) principles. Furthermore, process optimisations and data driven decisions lead to a reduction in cost per ton through predictive maintenance, savings on chemicals and fibers, a decrease in quality defects and improved asset utilisation. These advancements allow organisations to achieve greater efficiency and sustainability in their operations.

PM: What are the challenges in adopting digital twin tech in paper mills?

RC: Most paper mills still operate with limited digital interfaces and outdated control systems. The absence of real time data collection, connectivity, and standardised digital platforms makes deploying a digital concept technically challenging. Upgrading old machines, installing sensors, integrating software, and training personnel require significant investments—often without immediate visible ROI. This is a major deterrent, especially for mid-sized and smaller mills.

The paper industry has not historically invested in data managers, automation engineers, and domain experts capable of working together to design and run digital strategies for their production and business improvements effectively. Operational staff often lack exposure to digital tools. Conversely, IT or digital teams may lack process domain insights. This gap hinders collaboration and slows down adoption. On the other hand, our country has vast resources to take on these challenges – it is only essential to commit to defined visions accordingly.

American and European mills have developed a robust digital ecosystem that encompasses everything from their supply chain systems to their finishing lines. Transitioning to digital twin technology for these mills would be relatively straightforward and require minimal capital investment.

PM: What do you see as the future of digital twin technology in the paper industry globally?

RC: To remain competitive, mills must embrace digital transformation and actively leverage them to drive operational efficiency, reduce waste, and meet sustainability goals. Digital transformation is no longer optional; it’s a strategic imperative for survival and growth in a rapidly evolving industry landscape.

Also Read: Towards Future-Ready Enterprises: Advancing Innovative Water Solutions

PM: How is Bellmer contributing to this development in the global pulp and paper industry?

RC: Bellmer strongly advocates digital transformations in Paper Industry. The company consistently encourages integration of cutting-edge sensors, IoT-enabled systems, and ERP connectivity into its equipment and solutions. This innovative approach not only optimizes machine performance but also establishes a solid foundation for data-driven operations and the deployment of future-ready digital support structures and services.

PM: Please comment on the current progress of automation in the Indian paper industry. How far are they from having digital twinning in their mills?

RC: Indian mills have made significant advancements in automation, particularly in control systems, remote monitoring, and the integration of Internet of Things (IoT) technologies. These developments position them favorably for the gradual adoption of digital technologies, beginning to focus on specific processes related to fiber savings and power. However, the implementation of comprehensive, end-to-end digital concepts across entire mill operations remains in its early stages. Indian mills are quite away from this development, and it is likely to take a couple of years to get it on stage, but I am convinced those who will, will be the future winners.

Indian mills have made significant advancements in automation, particularly in control systems, remote monitoring, and the integration of Internet of Things (IoT) technologies. These developments position them favorably for the gradual adoption of digital twin technology, beginning to focus on specific processes related to fiber savings and power.