Bellmer India is arguably the first Indian company manufacturing the state-of-the-art calenders, equivalent to a European calender…

Paper Mart interviewed Mr. Ranajoy Chowdhury, Managing Director, Bellmer India Pvt. Ltd., wherein he outlines the – overview of Bellmer India, the capabilities, Turbo Calender – TURBOCal, presence in the Indian paper mills, and the future plans of the Company.

Paper Mart: At the start, could you please present a brief run-through of the Company – Bellmer India Pvt. Ltd and its market footprints. What are the significant achievements for the company so far?

Ranajoy Chowdhury: Bellmer India Private Limited, formerly known as – GapCon Engineering Pvt. Ltd., is an Indo-German joint venture, which was conceived with the envisaged growth in the demand of modern pulp and paper machines in India. The production of correctly engineered paper machine calenders has always been an uphill task in the world over, considering that the knowledge base was closely guarded in Europe. With the advent of Bellmer India, the primary objective was to bring to India for the first time, away from the European shores, the knowledge, experience and know-how on the paper machine calenders and its related services. A state-of-the-art investment was set up in the year 2014, to engineer, manufacture and service complete paper machine calenders and crown compensated (CC) rolls. Apart from investing in knowledge and technology for calenders, the investments were strategically rendered in arguably one of the best grinding machines in India, along with an automatic test bench for simulating the CC roll operation on a real-time basis.

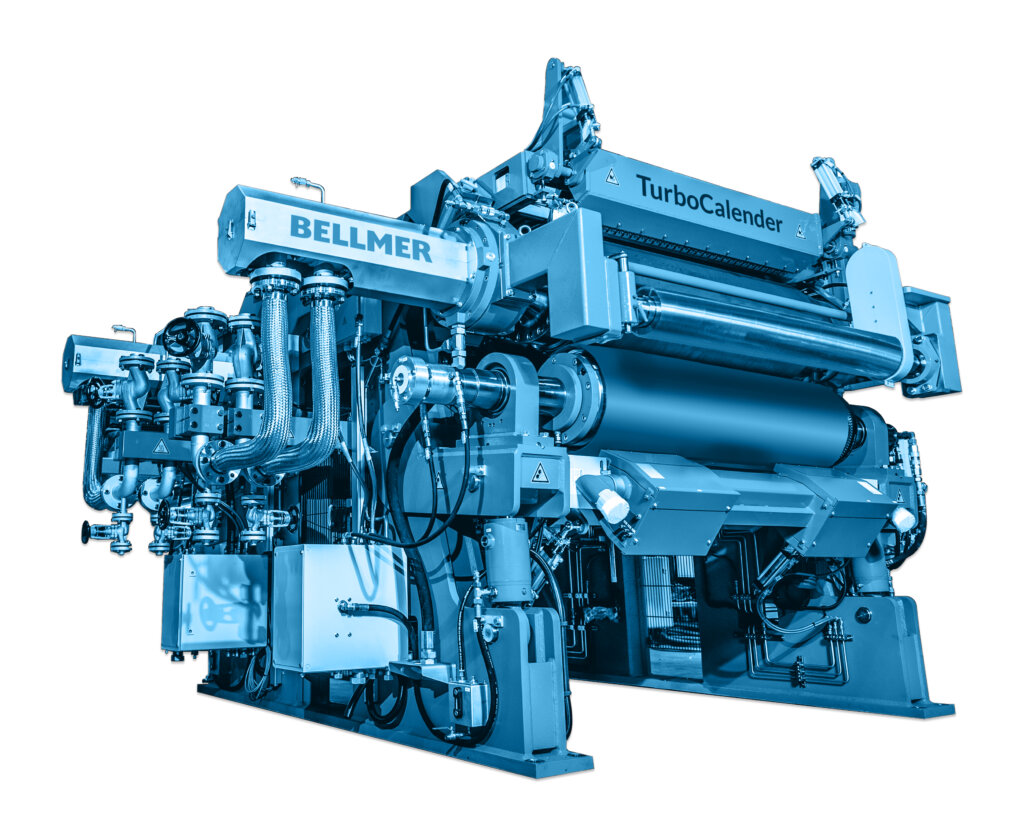

Bellmer India has been showcasing an economical and ergonomical calender named TurboCalender, with German precision and engineering support, felicitous for the Indian market. With this, we offer a complete state-of-the-art new calender TurboCalender and also, we utilize the existing equipment as applicable to build a new TurboCalender or rebuild an existing Multinip to a modern TurboCalender. This comes with both – the hard or soft nip concept, which provides paper mills a technically advanced tool to directly influence their paper/board surface properties.

Bellmer’s team in India, has been working relentlessly, to rectify the previous mistakes, as observed in various installations of calenders, bringing to the market correct solutions with a driven CC roll, importance of a heated roll and application of multizone CC rolls.

PM: Please describe the company with respect to – the manufacturing capabilities and also outline an overview of the infrastructure of your facility.

RC: Bellmer India is involved in a number of activities as a prelude to the manufacturing efforts of TurboCalender, in their state-of-the-art plant, which is located close to Kolkata. Some of the activities include – engineering of complete tailor-made calender, procurement, and assembly of both – calender CC rolls and complete calenders. In addition, our capabilities also include – service and repair of all kind of CC rolls, hydraulic test bench for CC rolls, grinding, balancing and repair of all functional rolls, quality control and training.

PM: Kindly present an overview of the Turbo Calender – TURBOCal. How do you think Turbo Cal is positioned to provide paper mills a technically advanced tool to directly influence smoothness, two-sidedness, bulk, gloss, and profile?

RC: TurboCalender is a smart surface treatment tool, which can be designed for multiple applications as a pre- and post-calender, which would directly influence features such as – sizing, two-sidedness, caliper profile, gloss and smoothness. The applications are all directly related to the relevant surface property improvements, influencing the final product, with its feel, optical properties and printability. Bellmer India is arguably the first Indian company manufacturing the state-of-the-art calenders, equivalent to a European calender, both hard and soft, for all grades and application.

PM: Elaborate on some of Bellmer India’s recent associations and projects executed for the paper mills in India? What was the scope of the supplies and how do you think it will benefit the mills in the long run?

RC: There has been an aggressive technical campaign in the market, to rectify the previous mistakes in the supplies of calenders, bringing to the paper mills, correct solutions with a driven CC roll, heated roll concept and usage of multizone CC rolls. Bellmer India was the first company to introduce the concept of integrated loading system in BILT, the usage of two multizone CC rolls in Khanna Paper Mills, apart from numerous modern pre calenders for coated board, LWC (lightweight coated paper) etc. in the market. Our pre calenders are working in nearly 50% established coated board manufacturers in India, for instance, Deevya Shakti Paper Mills, Sripathi Paper & Boards, Khanna Paper Mills, Sahota Papers, Emami Paper Mills, to name a few. However, it’s just an extract, with benefits attributed to properties such as – gloss and bulk. Our objectives are to realize the dream of Indian paper makers, to have a tool which directly influences the surface properties without compromising on strength.

PM: Having expertise in the design, manufacturing, supply, and commissioning of calender, film press, deflection compensation rolls and its corresponding services, and also the rebuild of any existing calender; could you please shed some light on the necessary capabilities of the company which enables it in undertaking turnkey projects?

RC: Bellmer Group is fully equipped to supply complete machine from the headbox to the reel, and as an alternative, all relevant key sections comprising of the headbox, top-former, shoe press, film press, coater, pre- and post-calender, reel and winder. At this juncture, the Indian operation is restricting its scope to supply and manufacturer of complete paper machine calenders and its related services. However, in due course of time, depending on the market pre-requisites, the further decision to append its product range, and to include the key sections would be introduced. Further, the customers should feel free to approach our counterparts in Europe for other key sections or for turnkey project machines.

PM: How do you view the Indian pulp and paper industry with respect to the demand for modern calenders? Also, what is your viewpoint with respect to capacity expansions, quality enhancement, and productivity improvements in the pulp and paper industry?

RC: As stated earlier, the investment in Bellmer India was based on the envisaged increase in the consumption and growth in the Indian market. Today, the Indian market is certainly aware of the cheap imports and its impact on the surface properties of paper/boards and herein lies the growth in demand by the Indian paper mills for a modern and efficient calender. In fact, I would like to emphasize that security for all investments, movement in tandem with the growth in demand, the return on investment would come only with the product having improved surface properties, i.e., with a Bellmer TurboCalender.

PM: Please outline on the recent product developments at your end and the upgradations you have introduced in the recent past at your production unit. Also, what is the future roadmap of Bellmer India going forward?

RC: At present, we are considering to make investments in our existing operation to append our capacity with respect to both – space and manpower, to exceed the existing capacity for the supply of new TurboCalender and related services. There has also been a reasonable advancement in developing a full-fledged automation team in India, not just for TurboCalender but also in Bellmer Shoe Press – TurboPress.

Depending on the market-demand and trends, we will plan to introduce technologically advanced equipment, which will be manufactured in India, and will act as a replacement for expensive imports.