Belluga Papers Private Limited is a modern high tech enterprise dedicated to production and sales of environmentally friendly products. The company is a leading supplier for the national and international market segment and is ISO 9001: 2015 certified, hence providing full guarantee in product quality, safety and environment protection. The company is one of the foremost manufacturers in various industries having a good market share and have been deeply engaged for business in India, Sri Lanka, Bangladesh, Nepal, Bhutan, in European Nations like Turkey, Romania, Germany and more. In a recent conversation with Paper Mart, Mr. Aman Bajla, Director, Belluga Papers, gave an overview of his company, manufacturing operations and product line, along with the current trends in the biodegradable tableware market.

Company’s Overview

We at Belluga Papers believe ‘Quality is not an Act, It’s a Habit’. Having experience in railways and tea processing for 25 years gives us an edge to accelerate in the paper industry. We are an ISO 9001 : 2015 certified company and follow all the quality control practices. We take pride in having a great team of trained and helpful people who are easily available to attend your requirements. Using the latest machines and technology we thrive to improve the quality, reduce the wastage and hence benefit our customers. Our company has been trying to give the best to the tableware industry and make regular developments. We have been a foremost manufacturer in various industries having a good market share and have been deeply engaged for business in India, Sri Lanka, Bangladesh, Nepal, Bhutan, in European Nations like Turkey, Romania, Germany and more. We constantly strive for improvements and innovations that enhance our performance, securing a healthy environment for future generations. Our outlook is for continued growth, and we plan on increasing our manufacturing capability, positioning ourselves to be one of the world’s fastest growing manufacturers.

Watch: JMC Paper Tech Launches New Subsidiary JMC Papers

Manufacturing Operations & Product Line

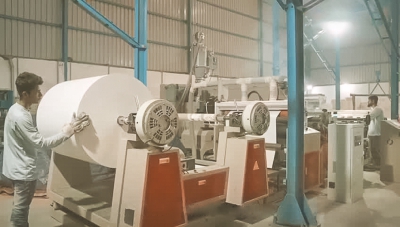

We procure the materials from the best mills across the country like ITC, Century, etc. which helps us to offer the best quality product. Every product has a different manufacturing process. We use coating machines, slitting, printing, cutting and shrink machines for most of our products. Currently, we have a capacity of 1200 MT/month which we are planning to increase by the end of this year. A major chunk of our revenue is through the tableware sector. We make the raw materials which are used by paper cup , paper straw, plate and box manufacturers and more. We make paper cup blanks of various sizes ranging from 30 ml to 300 ml. We also make paper plate circles of sizes 6 inch, 7 inch, 8 inch, 9 inch, 12 inch, 13 inch, 14 inch, etc. Our firm is engaged in offering poly coated cup stock paper, poly coated poster paper, poly coated maplitho paper, poly coated chrome paper, etc. We do promote recycled paper as well as it reduces the cost for the end users.

Also Read: Greenvale Nurtures Sustainability with Over 60 Eco-Friendly and Biodegradable Products

Trends In Biodegradable Tableware Market

With regard to the biodegradable crockery, we assume that there would be a drastic increase in the market in upcoming years. Our company keeps working on the development round the clock. For instance, we have come up with more than 6 different grades of paper and boards for paper plate manufacturers. The biodegradable tableware industry has been increasing drastically but talking specifically about bagasse tableware, there is an acceptance in the country but most of the bagasse manufacturers are targeting exports . Being a premium product in the sector, it might take a bit more to be accepted by the masses.