Indian paper mills are implementing digital twin technology to optimize efficiency and process control. Early pilots show promise as manufacturers move from machine-level monitoring to intelligent, mill-wide optimization.

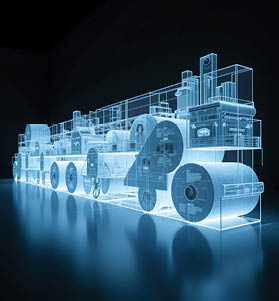

Digital twins are the digital models or virtual replicas of real-time factory systems and processes. These replicas mirror physical production systems through continuous data streams, enabling predictive maintenance and real-time process adjustments. The technology arrives as India’s paper sector seeks competitive advantages through operational excellence.

As said, digital twin systems create precise virtual models of equipment like digesters, bleaching sequences, and paper machines, allowing operators to test scenarios without disrupting production. Market momentum supports broader adoption. The global digital twin market is projected to expand from USD 10.1 billion in 2023 to USD 110.1 billion by 2028, growing at a CAGR of 61.3%, as per market reports. India’s segment crossed USD 546.7 million in 2024, with forecasts indicating eightfold expansion by 2030. Paper Mart looks at industry opinions on digital twin technology, a subject of much debate in manufacturing.

Watch: In Pursuit of Lesser Water Footprint

Redefining Mill Intelligence

Earlier applications of digital twins were largely limited to machine-level monitoring. Today, paper mills are turning to process-level twins that can model entire workflows, from chemical dosing and bleaching to drying and winding, simulating variables and predicting outcomes before implementation.

At ITC PSPD, the digital twin journey has started with in-house development targeting critical unit operations. The company has successfully developed a digital twin for its digester process, coded internally using Python and Tkinter. This localized simulation tool provides real-time visibility and control over one of the most complex and critical stages of pulping.

While not mill-wide, this tool demonstrates how even localized digital twins can drive operational gains when grounded in process expertise. “One of the most strategic areas for applying process digital twins are digesters which are the starting point of the pulp production line,” said Gaurav Kataria, VP Digital (Manufacturing). “Having an in-house digital twin in place for such a process helps us move from reactive troubleshooting to real-time, data-driven decision making, leading to improvements in efficiency and quality across the entire value chain.”

Kuantum Papers has developed a customized digital simulation system, internally conceptualized and implemented, that mirrors specific high-impact processes such as boilers and energy systems. Built using tools like dataPARC dashboards, model predictive controllers, and soft sensors, the system simulates dynamic operating conditions, suggests real-time corrections, and supports closed-loop optimization. It is not a comprehensive mill-wide digital twin, but rather a focused in-house initiative addressing key operational pain points. “We have successfully implemented a first-of-its-kind in-house Digital Twin system at Kuantum. It simulates critical processes based on historical and real-time data,” said a company official.

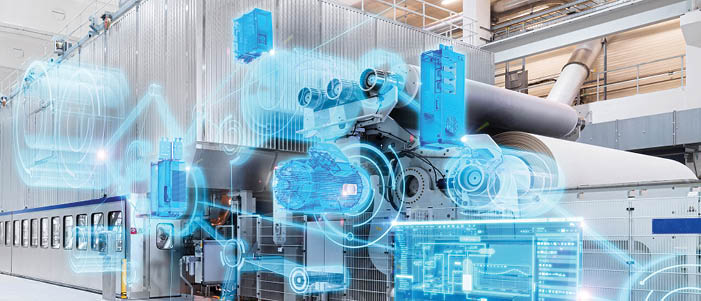

Trident Group, the world’s largest wheat-straw-based paper manufacturer, is currently piloting digital twin modules across its energy-intensive units, laying the groundwork for broader implementation. “In today’s global paper manufacturing context, digital twins are used to mirror mill operations, from pulp preparation to paper finishing lines, helping optimize machinery efficiency and quality control,” noted Rajnish Kumar Gera, CEO (Paper).

At Trident, these virtual models are being tested for real-time monitoring, predictive maintenance, and process simulation, particularly to improve paper conversion cycles, reduce waste, and enhance material yields. Backed by automation, ZLD systems, and sensor-based frameworks already in place, the company sees digital twins as the next leap in smart manufacturing, aligned with ESG goals and resource efficiency.

Building Digital Readiness Into the Machine Layer

“While digital twins are still nascent in Indian mills, there is increasing interest, especially among integrated and sustainability-driven manufacturers,” says Trident’s Rajnish Kumar Gera. Early adopters are already reporting tangible gains from digital twin deployments, validating the potential of this technology even in its nascent Indian context. At ITC PSPD, in-house models have enabled faster root-cause analysis and greater stabilization of pulp quality, critical to maintaining consistency in high-speed production environments.

“Digital twins are expected to evolve from visualization and diagnostic tools into predictive and prescriptive systems that can simulate scenarios, enable root cause analysis, improve process efficiencies, and prevent unplanned downtimes,” said Gaurav Kataria. The company’s digester twin has already demonstrated improvements in chemical dosing and fibre yield, while laying the groundwork for smarter, low-cost deployments across other unit operations.

Kuantum Papers leveraged its digital twin technology investments to achieve quantifiable operational gains, positioning the company ahead of competitors in sustainability performance. Its Model Predictive Control systems have brought about a 26% reduction in caustic soda, 24% in oxygen, and 10% in both hydrogen peroxide and chlorine dioxide consumption during the pulp bleaching process.

“Further, this rigorous process control also helped reduce effluent load and air emissions,” admits a senior executive from Kuantum Papers. “In terms of cost reduction, the savings on bleaching chemical consumption translate directly to lower production costs.”

At Trident Group, while full-scale deployment is still in progress, digital twins are being used strategically across energy-intensive areas to minimize waste and reduce process variability. These pilots complement the company’s established zero-liquid-discharge systems and biomass-based energy infrastructure, reinforcing its position as a circular economy leader.

“For Trident Group, which uses agri-residue fuel, digital twins can further drive resource conservation by reducing process variability and enhancing material yield,” informs Rajnish Kumar Gera. The Group sees digital twins not only as tools for internal optimization but also as pivotal enablers of traceability, emissions monitoring, and compliance in agri-residue-based production systems.

A Gradual but Certain Shift

Despite their promise, digital twins come with steep learning curves and structural challenges, especially in the Indian context. The initial investment required for integrating sensors, software platforms, and advanced analytics can be a major hurdle, particularly for mills operating on thin margins. “The upfront investment required for sensors, software and integration platforms can be significant, especially for mills with limited automation,” informs Kuantum Papers.

From a global technology supplier perspective, Bellmer India’s MD Ranajoy Chowdhury echoes the sentiment, “Upgrading old machines, installing sensors, integrating software, and training personnel require significant investments, often without immediate visible ROI.” Bellmer is embedding digital twin compatibility directly into its systems, using advanced sensors, IoT interfaces, and ERP-connected frameworks.

Older machinery complicates integration further, often requiring custom retrofits or hybrid control strategies. “Retrofitting legacy machinery with IoT sensors and data platforms can be capital-intensive and technically complex,” says Rajnish Kumar Gera. Customizing digital twin platforms for industry-specific applications presents significant technical hurdles for manufacturers. The pulp and paper sector faces particular constraints in adapting these systems to its complex production environments. “A key limitation is lack of domain specific models tailored to unique processes of pulp and paper manufacturing,” says Gaurav Kataria.

Beyond the infrastructure, the human element remains a critical bottleneck. Many mills lack the in-house expertise to interpret advanced data models, while frontline teams may resist adopting unfamiliar digital workflows. As operations become more connected, cybersecurity concerns and interoperability with legacy systems also become pressing.

Leading mills are tackling these barriers with strategic clarity. Kuantum Papers adopted a phased implementation approach, starting with basic data integration and visualization, before gradually rolling out MPCs in targeted areas. Trident Group is addressing the skill gap head-on with training programs and digital literacy initiatives, while ITC emphasizes the importance of domain-specific process modeling to avoid AI-driven inaccuracies.

Zooming out to the broader industry, the digital twin readiness spectrum is uneven. Tier-1 mills with scale, capital, and digital ambition are moving beyond proof-of-concept into strategic deployment. “Broader adoption will depend on strengthening certain foundational elements,” says Gaurav Kataria.

Tier-2 mills, though digitally curious, often stop short at basic automation, hampered by a lack of integrated platforms. At the other end, Tier-3 and SME players face the dual challenge of limited capital and low digital literacy, making digital twin adoption a longer-term prospect.

Still, the trajectory is unmistakable. “Mills are beginning to embrace Industry 4.0 technologies such as IoT, AI, and cloud computing, crucial foundations for effective digital twin deployment,” informs Rajnish Kumar Gera. Rising expectations around traceability, sustainability, and regulatory compliance are nudging all segments toward some form of smart manufacturing. Digital twin systems, whether partial or end-to-end, are likely to become a shared aspiration across mill sizes and geographies. “Traditionally, digital twins have been deployed at the product level, focusing on individual machines… However, real value in process industries like pulp and paper lies in moving towards process digital twins…,” says Gaurav Kataria.

“Indian mills have made significant advancements in automation, particularly in control systems, remote monitoring, and the integration of Internet of Things (IoT) technologies,” says Ranajoy Chowdhury. “These developments position them favorably for the gradual adoption of digital twin technology, beginning to focus on specific processes related to fiber savings and power.”

Also Read: ITC PSPD Develops In-House Digital Twin Technology Showcasing Cost-Effective Innovation

Technology for Today and Tomorrow

Indian paper manufacturers must now consider when, not if, digital twins become essential. Looking forward, industry leaders foresee plant-wide optimization frameworks, where energy, steam, water, and emissions are monitored and managed in real time. Operator training simulators based on live mill data may soon become standard, as will predictive maintenance ecosystems and closed-loop quality control systems.

As Kuantum Papers aptly summarizes, “India’s paper industry is on the cusp of a digital revolution. While the pace of adoption may vary, the trajectory is irreversible. Digital twins will be at the heart of this transformation, merging physical operations with virtual intelligence to build more agile, efficient and sustainable mills.” Trident’s Rajnish Kumar Gera adds, “Greater adoption is expected within 3–5 years, especially among vertically integrated and future-ready mills.”