Emami Paper Mills have made a significant stride in enhancing its water efficiency, increasing its recycled water usage by 28% within a single year. Notably, 30% of the company’s daily water consumption is fulfilled through reclaimed water and 50% of the treated water is repurposed for irrigation. In an exclusive interview with Paper Mart, Mr. Ashish Gupta, Senior President at Emami Paper Mills shares how the mill is leveraging high-efficiency Dissolved Air Flotation (DAF) units, scan showers, disk filters, and advanced membrane filtration technologies to minimize fresh water usage and advance water circularity across its operations.

Paper Mart: How has your understanding or approach to water circularity evolved over time? How close are you to achieving it?

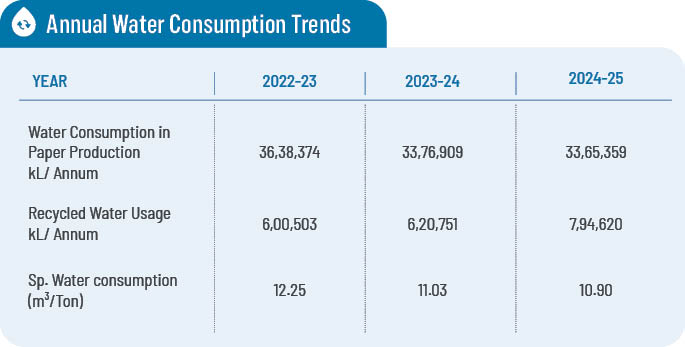

Ashish Gupta: Emami Paper Mills’ approach to water circularity has evolved from basic conservation to a comprehensive recycling and reuse model. Starting with specific water consumption of 12.6m³/ton of production in 2021-22, we have currently brought it down to 10.9 m³/ton, which is a reduction of around 13.5%.

PM: To what extent have you implemented internal water reuse, recovery, or circular systems (including ZLD, water loop closure, or rainwater harvesting)?

AG: We have significantly advanced in adopting water reuse and circular practices. At Emami Paper Mills, 30% of our daily water consumption is met through reclaimed water, which is reused internally for dust suppression, floor sanitation, horticulture, and ash conditioning; 50% of the treated effluent is used for irrigation, promoting sustainable water usage beyond our operations.

We have constructed 20 recharge wells with gravel filtration systems, for the replenishment of groundwater. These wells have a total recharge capacity of around 26,03,874m³ per year, which is 77% of our total water drawn.

These initiatives reflect our commitment to reducing depletion of ground water and moving towards a more circular water management system.

Watch: In Pursuit of Lesser Water Footprint

PM: Which technologies or solutions have you found most effective in reducing your freshwater consumption or increasing internal recycling?

AG: Installation of a scan shower in the wire section has helped in substantial reduction of fresh water consumption. Besides this, high-efficiency DAF (Dissolved Air Flotation) units, disk filters and advanced membrane filtration technologies etc. have also contributed in our efforts towards reduction of fresh water consumption.

PM: What are the biggest roadblocks (technical, financial, or regulatory) in achieving higher levels of water reuse or moving toward ZLD?

AG: As a large volume of water is required for manufacturing paper, the major challenge is the high initial investment and subsequent high operating costs of the water treatment systems. Newer manufacturing technologies therefore focus on reducing the consumption of water thereby reducing the investments in wastewater treatment and its operating costs.

However, the constraints of handling large volumes of water continue to remain with older paper machines, which are still in operation.

PM: How do local or national regulations affect your water management goals? Have sustainability mandates accelerated your water-saving initiatives?

AG: The regulatory requirements and ESG commitments have accelerated our efforts. Compliance with CPCB/SPCB norms and increased customer requirement of sustainability reporting have further given us a push.

PM: Have your investments in water reuse or ZLD technologies paid off in terms of savings, efficiency, or compliance?

AG: The investments in water reuse strategies and technologies have resulted in reduced usage of freshwater and lower effluent load, thereby resulting in cost-effectiveness in the long run.

Also Read: Seshasayee Paper and Boards Aims to Achieve Full Water Circularity

PM: Do you involve technology providers in planning or customizing your water treatment systems? Any successful collaborations worth sharing?

AG: We work closely with vendors to customize water treatment systems, and to suit our operational needs. We also involve vendors wherever newer technologies are involved like in the case of scanning showers. These collaborations enhance our understanding of the latest technologies, thereby improving our water treatment efficiency.

PM: Have you considered or implemented digital twins to simulate, monitor, or optimize your water use? What kind of improvements could such systems bring to your operations?

AG: Though we use real-time online flow and consumption monitoring devices to monitor and control consumption through digital flow meters, we are yet to explore the use of a digital twin to stimulate the data. Digital stimulation would be useful in optimizing water distribution and anticipating demand and improving long term planning.