Heinzel Group is intensifying its water reduction efforts by enhancing water reuse systems and closing the water cycle loop across its mills, reaching a level of 89.2% water reuse in 2024. In an exclusive interview with Paper Mart, Mr. Sebastian Heinzel, CEO at Heinzel Group. shared the Group’s goal to reduce per metric tonne of freshwater use by 25% by 2030, driven by its ‘Closing Cycles’ motto and a stronger collaboration across sites in Laakirchen, Pöls, and Steyrermühl.

Paper Mart: How has your understanding or approach to water circularity evolved over time? How close are you to achieving it?

Sebastien Heinzel: The Laakirchen site introduced an ISO 14001 environmental management system, as early as 1995, at a time when environmental standards were still the exception rather than the rule. Today, all industrial sites within Heinzel Group are ISO 14001 certified, with selected sites such as AS Estonian Cell and Bunzl & Biach also meeting Eco-Management and Audit Scheme (EMAS) requirements.

For decades, we have effectively prioritized resource optimisation in our daily operation, saving water, air, and soil, as well as minimizing harmful emissions. We actively prevent negative environmental impacts at every stage of production, and the legal standards are the minimum requirement for meeting our environmental responsibilities.

Responsible water use is central to our sustainability strategy. We have implemented effective measures to reduce freshwater consumption by closing the water cycle loop as much as technically feasible, and by continuously improving how we monitor and manage water use. Through these proactive efforts, we aim to reduce our per metric tonne of freshwater withdrawal by 25% by 2030.

Our active measures to save water in every step of production, ongoing investment in water-saving technologies and certified environmental management systems reflects our long-standing commitment to water conservation.

Our motto ‘Closing Cycles’ symbolizes the higher degree of inter-site collaboration, particularly between our sites in Laakirchen, Pöls, and Steyrermühl. This close collaboration between the management teams of the various Heinzel Group subsidiaries and the holding company improves our strategic and operational effectiveness.

Watch: In Pursuit of Lesser Water Footprint

PM: To what extent have you implemented internal water reuse, recovery, or circular systems (including ZLD, water loop closure, or rainwater harvesting)? Which technologies or solutions have you found most effective in reducing your freshwater consumption or increasing internal recycling?

SH: Water conservation is a strategic priority at Heinzel Group, with a strong commitment to reducing freshwater consumption across all our paper and pulp production sites. We have continuously invested in water-saving initiatives and monitoring projects to enhance water efficiency.

In 2024, Laakirchen Papier AG commissioned a sludge dewatering plant to enable the efficient drying of organic and fiber sludges. This investment made a significant contribution to optimizing sludge treatment. The plant includes high-performance centrifuges, screw conveyors to transport the dewater sludge, and a sludge silo with a truck unloading station. To further reduce emissions from the new system components, odor-minimizing measures have been implemented in the sludge dewatering system. All sections of the sludge dewatering system and the sludge loading station are connected to an end-to-end air extraction system which directs exhaust air through an organic filter. This effectively eliminates unpleasant odors, and minimizes the impact on local communities.

In the same year, the facility also commissioned a second anaerobic plant to significantly increase the capacity of wastewater treatment and enable the use of clean water even more efficiently. This extended plant includes a pre-acidification tank with a capacity of 3,000 m³ as well as two anaerobic reactors, each with a volume of 3,400 m³. The biogas from the anaerobic treatment plant is used for steam production (10% of total gas needed) instead of natural gas so that we can save up to 18,000 tons of CO2 yearly.

Laakirchen Papier AG obtains the water for the entire production processes from several wells located on the Traun. The wastewater is 100% processed using the wastewater treatment plant and discharged into the Traun in compliance with official limits.

In 2023, the fresh water withdrawal at Laakirchen Papier AG is approximately 7.926 million m³ while the consumption is only 0.512 million m³. It is also worth mentioning significant progress has been made at the Laakirchen facility in terms of reducing drinking water. By means of improving consumption monitoring, it was possible to reduce drinking water usage between 2021 and 2023 by 74%, which is equivalent to the average annual tap water consumption of 760 people.

At AS Estonian Cell, the reuse of cooling water in centrifuges was implemented, leading to potential savings of 2,500 m³ per month. Further, in general reusing of the surface water extracted from the rivers (all in low water risk areas according to the World Resource Institute) several times is key for optimizing the freshwater use.

AS Estonian Cell also performs comprehensive marine surveys every five years. These investigations performed by the University of Tartu evaluate the quality of the seawater, marine flora and fauna and the concentrations of organic and inorganic substances in commercial water to ensure that the seawater in the wastewater discharge area – around 2.4 km from the coast – is clean and has no negative environmental impacts can be detected.

At Zellstoff Pöls AG, the key measures include the installation of a new control system with the capacity to save 400,000 m³ of water per year. The mill obtains the majority of water from the neighboring Pölsbach. The cooling water is fed back into the Pölsbach on the basis of official requirements (temperature, heat load and quantity). The processed wastewater is 100% purified in the wastewater treatment plant before being discharged into the Pölsbach.

The company has reduced its water withdrawals to 15% per metric tonne of pulp and paper produced. Further, a detailed analysis, numerous process-based optimizations and technical innovations have also been implemented to conserve and treat the water resource. In the last three years, seven sub-projects have been implemented and further action is already being planned.

Further, regular internal inspections and third-party audits are conducted to ensure compliance with environmental standards at all sites and keep emissions well below legal limits. AS Estonian Cell, since the start of production, has held an Environmental Complex Permit (ECP, No. 1) and has continuously invested in environmentally friendly technologies to meet ECP requirements. In 2024, this subsidiary extended its ECP to enhance the monitoring of fine particulate matter emissions. This includes the implementation of third-party measurement procedures to effectively monitor and reduce emissions from the fluid bed dryer.

Heinzel Group has been a reliable partner to local communities, ensuring that both their own and municipal wastewater treatment meet environmental, and quality standards set by authorities. Every step we take, every decision we make, and every investment we pursue contributes to our vision of a clean environment – not just for today, but for the future.

In 2023, the fresh water withdrawal at Laakirchen Papier AG is approximately 7.926 million m³ while the consumption is only 0.512 million m³.

PM: How do local or national regulations affect your water management goals? Have sustainability mandates accelerated your water-saving initiatives?

SH: Water is the basis of all life on Earth and therefore key to environmental stability and human well-being. At the same time, water is also an important element in many industrial processes including the production of pulp and paper. We need to use water responsibly and efficiently in order to protect our water sources and the water cycle.

Adopting water-saving technologies and modern water treatment plants are a means of actively protecting the environment – to maintain biodiversity and environmental stability in the region. That is why water management is one of our main priorities by 2030 and we have put it on the agenda, setting water reduction targets and a roadmap. The current regulations and market demands are certainly helping to manage water consumption and to internally raise awareness of the importance of freshwater reduction.

At Zellstoff Pöls AG, the installation of a new control system has the capacity to save

400,000 m³ of water per year.

PM: Have there been any unexpected challenges while carrying out the water initiatives and how have you solved it?

SH: Responsibility is not just taking initiatives but also responding promptly and effectively to environmental incidents. In 2024, two unforeseen incidents occurred. Early in the year, ground natural limestone (calcium carbonate, used as a filler material in paper production) escaped from an enclosed system due to a defective compensator. While harmless to people, fauna, and flora, the substance briefly turned the Traun River white. Immediate action by the Laakirchen site’s environmental department, in close cooperation with the fire brigade and local authorities to ensure a swift resolution of this effect, preventing any further impact.

Also Read: APP Group Embraces Circular Bio-Economy, Integrates Water Treatment with Energy Recovery

PM: How do you see your water use evolving in the next 5–10 years? What would “full circularity” look like in your operations? What kinds of support in terms of technology, partnerships, or policies would help you get there?

SH: We have a clear pathway to reduce our freshwater consumption by identifying practical steps, through technology, process optimization, or operational changes, that will lead to the decrease in the amount of fresh water used in our operations. Our company will mainly focus on full circularity in water use wherein we will be closing the water loop wherever it is technically feasible. The water will be reused multiple times within the pulp and paper manufacturing process rather than discharging it after one use. The water will be collected, treated, and reused internally as much as possible.

PM: What is your current annual water consumption, and how has the consumption reduced over the past few years?

SH: In 2024, Heinzel Group recorded specific freshwater withdrawals of 22.2 m³/t, up from 20.7 m³/t in the previous year. This increase was primarily due to two factors: the conversion of the new paper machine (PM6) at the location in Steyrermühl, which required water for initial quality tests and pilot operations, and the continued operation of wastewater treatment and energy plants at Heinzel Raubling Paper Gmbh despite the production stop.

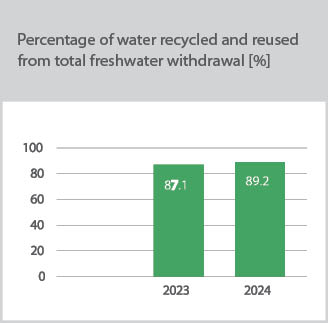

In FY23, 87.1% of all freshwater is used multiple times in the production process. In FY 2024, the share of water reused at all mills of Heinzel Group was increased to 89.2 %. As in previous years, 100% of all water withdrawn is safely treated before being discharged into nearby rivers or into the sea.

All in all, our commitment to a clean environment is a continuous process rather than a one-time milestone and our goal is to actively contribute by not only complying with the strict regulations on water pollution but also continuously improving our water conservation and water treatment process through consistent use of the best available technology and proactive measures to achieve success.

ABOUT

HEINZEL GROUP

Heinzel Group produces market pulp and packaging paper at three locations in Europe and trades in pulp, paper, recycled fibre and packaging solutions worldwide. With the production companies heinzelpöls, heinzelpaper and Estonian Cell, Heinzel Group is one of the most important pulp and paper producers in Central and Eastern Europe. The three trading companies of Heinzel Group – heinzelsales, Europapier and Bunzl & Biach – respond flexibly to the most diverse customer needs internationally. The growth success of the Heinzel Group is based on entrepreneurial spirit and a focus on long-term partnerships. Sustainability is the focus of all its activities.