IBS Paper Performance Group is a leading supplier of technologies and services for the global paper, board, pulp and tissue industry. With over 50 years of experience, IBS is the unrivalled expert for paper machine optimization. Therefore, a professional team of more than 30 papermaking experts around the world is committed to boost its customers’ performance forward – everyday!

Interview with Mr. Alfred Staber, Area Sales Manager, IBS Paper Performance Group, Austria.

Q: What is that makes IBS PPG so successful in the pulp and paper industry?

AS: The IBS Paper Performance Group stands for innovative technologies and excellent products in the world of papermaking. Our comprehensive portfolio covers a wide range of applications. We have eleven strong brands under our roof, all with their own technology and history. And we are not only providing machine components — with over 50 years of experience in the industry, we are providing tailor-made system solutions paired with technological know-how to our partners worldwide. A further secret of being successful is for sure that our development team never stops working; we are continuously improving our solutions. Additionally, IBS employees are experts in each section of the paper machine. A team of well-experienced engineers and papermakers is evaluating each inquiry to find the best solution for every application. This is what makes us strong– we are always one step ahead.

“Today, more than 160 iTABLE™ have been already installed worldwide. The first one was installed in India in 2018, and another one will be installed in the 2nd half of 2021.”

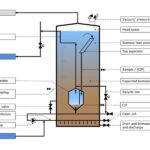

Q: IBS is called to be the inventor of intelligent dewatering solutions in the wire section. What is the iTABLE™?

AS: The idea of inventing an intelligent forming table was already conceived in the last century. After years of research and development, the first fully adjustable wire table was installed in 2007 — called iTABLE™. It gives papermakers flexibility in terms of changing foil angles, heights, pitch, and vacuum settings – and the best part is: Those settings can be done by pushing a few buttons within a couple minutes. The iTABLE™ is not a standard item, it is a tailor-made solution and involves an extensive survey of the machine and the papermaker’s targets. Many mills implement the iTABLE™ in steps. In the last few years, IBS has equipped many machines with automatic vacuum control systems as the 1st step of an iTABLE™ concept. Vacuum has been one of the neglected areas in paper machines and we can have a whole separate discussion on this topic another time.

Q: How many iTABLE™ have been installed already?

AS: Today, more than 160 iTABLE™ have been already installed worldwide. The first one was installed in India in 2018, and another one will be installed in the 2nd half of 2021.

“Our target is to bring high sophisticated products, system solutions and environment-friendly technologies (Energy and water saving products) to our Indian customers.”

Q: Which machines can be equipped with an iTABLE™?

AS: In India, we had the experience that many machines have to produce small order quantities and therefore paper grades need to be changed very often — the best conditions for an iTABLE™. Besides a very few dedicated newsprint machines, all medium and large machines in India are perfect candidates for an iTABLE™.

Q: What is your impression of the Indian paper industry?

AS: The Indian paper industry is one of the fastest growing markets in the world. Considering the number of paper machines currently in operation, India has a huge potential. IBS PPG has a strong presence in India thanks to its technical capabilities, know-how, and a network of IBS’s representative in India. Our target is to bring high sophisticated products, system solutions and environment-friendly technologies (Energy and water saving products) to our Indian customers. With regard to COVID-19, I am quite sure that this crisis is not permanent and the Indian paper industry will revive soon and return stronger than before.

“Currently, the IBS Paper Performance Group is expanding it’s headquarter in Teufenbach-Katsch (Austria) with a distinctive building — the IBS Tower.”

Q: Environment is one of the most important things nowadays. What contribution does IBS PPG make?

AS: Environment-friendly and resource-saving products are one of the main focuses of IBS PPG. We spend 5% of our turnover in research & development. You may have heard of ultra-high-pressure cleaning systems for machine clothing called “FabriCare”& “FabriClean”. These systems clean forming fabrics, press felts and dryer screens online at a pressure between 60 and 280 bars with fresh water only — without any chemicals, steam or vacuum. Compared to conventional high-pressure showers, these systems save 80% to 90% of fresh water. Nearly 20 FabriCare/FabriClean systems have been already installed in India and an additional 15 are lined-up for commissioning in 2021. Currently, the IBS Paper Performance Group is expanding it’s headquarter in Teufenbach-Katsch (Austria) with a distinctive building — the IBS Tower. It is not only intended to create new space for further growth, but also to put down a marker.

“The building is intended to make our internationally extremely successful company and its attractive career opportunities visible to the outside world,” as said by our owner Mr. Klaus Bartelmuss.